Steam turbine generator set torsion measuring method based on CCD photographing technique

A technology of turbogenerators and turbogenerators, applied in measuring devices, testing of machine/structural components, testing of static/dynamic balance, etc., capable of solving problems such as poor dynamic characteristics and limited measurement locations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

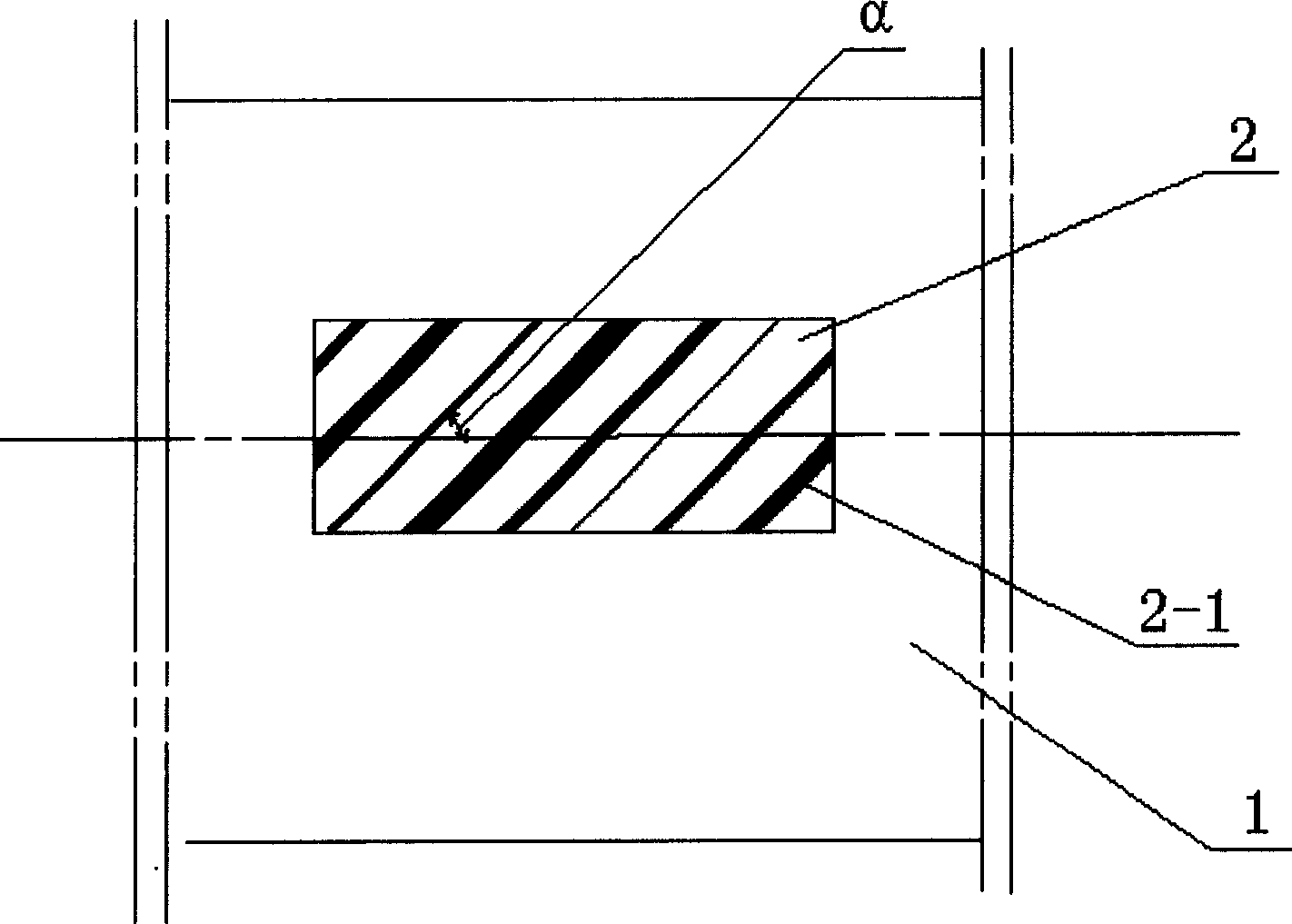

[0015] Specific implementation mode one: the following combination figure 1 This embodiment will be specifically described. It is achieved through the following steps:

[0016] One, use several CCD cameras to take pictures of the paper tapes 2 with patterns pasted on different positions on the length of the turbine generator shaft 1 in front of the lens respectively, and each CCD camera takes pictures synchronously; two, take each CCD camera The images of the images are sent into the computer respectively, and the instantaneous linear displacement of the paper tape 2 at the corresponding position of each CCD camera is calculated respectively; 3. According to the instantaneous linear displacement of the paper tape 2 at the corresponding position of each CCD camera, the instantaneous change of the steam is calculated. Speed increment or twist angle increment of wheel generator shaft 1.

[0017] The pattern on the paper tape 2 is a plurality of black stripes 2-1 with a certai...

specific Embodiment approach 2

[0019] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step 2, a generalized correlation delay estimator based on adaptive technology is used to calculate the instantaneous displacement. The displacement can be regarded as the delay on the position coordinate axis, so the calculation method of the displacement adopts the generalized correlation delay estimator based on the adaptive technology. The generalized correlation delay estimator is calculated by using the overall information of the image signal, so that a higher signal-to-noise ratio can be obtained, and the requirements for image clarity and focus are relatively low. After adding adaptive technology, the estimator can adapt to the time-varying measurement environment. The calculation process of this estimator is an iterative process, and the iterative algorithm is as follows:

[0020] ε(k)=x 2 (k)-y(k)

[0021] y ( k ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap