A grain conditioning method before steam flaking

A technology of steam tabletting and preparation method is applied in the preservation method of animal feed raw materials, animal feed, animal feed and other directions, which can solve the problems of limited improvement of grain nutritional value, inability to effectively achieve grain starch gelatinization, etc., and improve production performance. , increase the utilization efficiency and increase the effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

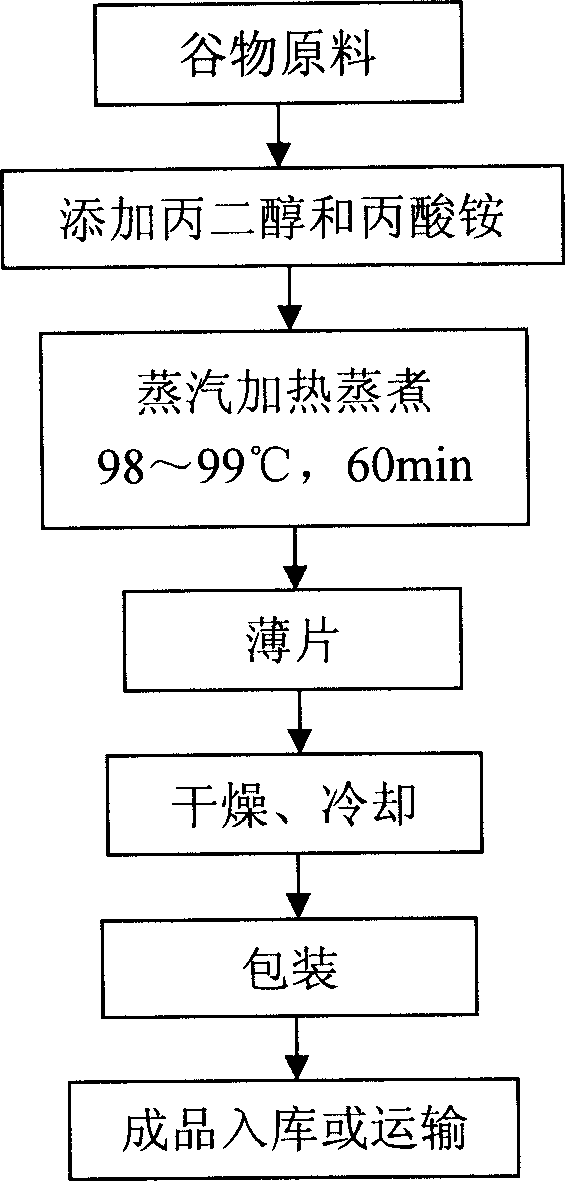

[0015] Depend on figure 1 It can be seen from the process flow diagram shown that the present invention is to pre-treat and prepare the grains to be steam-pressed. This pre-treatment preparation method is to add propylene glycol or ammonium propionate to the grains to be steam-pressed, or add propylene glycol or ammonium propionate simultaneously. ammonium propionate.

[0016] Table 1: Nutrient composition

control group

0.1%

0.4%

1.0%

Dry matter (%)

Crude protein (%)

Glucose Utilization Rate (%)

Gelatinized starch (%)

Gelatinized starch (kg / t)

84.7±0.31

8.7±0.22

58.1±1.74 c

50.9±1.99 c

308.3±26.9 c

85.0±0.54

8.5±0.23

59.8±1.80 c

52.1±2.13 c

313.7±29.1 c

83.7±0.28

8.8±0.35

69.7±1.82 a

59.5±2.18 a

360.5±22.5 a

84.0±0.22

8.8±0.12

65.1±1.23 b

54.9±1.54 b

331.2±18.3 b

[0017] Table 2: Nutrien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com