Mixed liquid additive for feed and preparation method of mixed liquid additive

A liquid additive and mixing technology, applied in the direction of animal feed, application, additional food elements, etc., can solve the problems of material agglomeration, unfavorable mixer sealing, etc., to improve utilization rate, avoid adverse effects, and improve feed quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

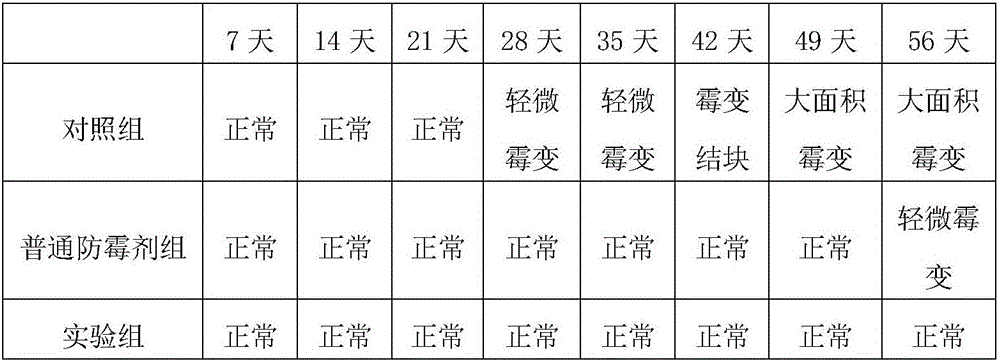

Examples

preparation example Construction

[0040] A method for preparing a mixed liquid additive for feed, comprising the following steps:

[0041] (1) According to the proportioning of antifungal agent 40-60%, Tween 5-15%, Span 5-15%, polyethylene glycol glycerol ricinoleate 10-20%, water 5-30%, each Component weighing;

[0042] The fungicide is selected from one or more of propionic acid, benzoic acid, sodium diacetate, ammonium propionate, sodium propionate or calcium propionate

[0043] (2) Put the antifungal agent into the finished product mixing tank first, stir and mix, add formic acid or sodium hydroxide according to the pH value of the antifungal agent, adjust the pH value of the antifungal agent to 5.8-6.2, and mix evenly to obtain the antifungal agent pretreatment liquid;

[0044] (3) Add Tween, Span and polyethylene glycol glycerol ricinoleate into the emulsifier pretreatment tank, and add water, stir and mix for 5-10 minutes to obtain the emulsifier pretreatment liquid;

[0045] (4) Add the emulsifier p...

Embodiment 1

[0052] Embodiment 1: The mixed type liquid additive for feed is made up of the following components by mass percentage: Propionic acid 20%, sodium diacetate 20%, Tween 5%, Span 5%, polyethylene glycol glycerol ricinoleate 20%, water 30%. The preparation method is as follows:

[0053] (1) each component is weighed by the above-mentioned proportioning;

[0054] (2) Put the components of the antifungal agent into the finished product mixing tank first, stir and mix, add formic acid or sodium hydroxide according to the pH value of the antifungal agent, adjust the pH value of the antifungal agent to 5.8, and mix evenly to obtain antifungal Agent pretreatment solution;

[0055] (3) Add Tween, Span and polyethylene glycol glycerol ricinoleate into the emulsifier pretreatment tank, and add water, stir and mix for 5 minutes to obtain the emulsifier pretreatment liquid;

[0056] (4) Add the emulsifier pretreatment solution obtained in step (3) into the finished product mixing tank eq...

Embodiment 2

[0057] Embodiment 2: mixed type liquid additive for feed, is made up of the component of following mass percent: benzoic acid 20%, sodium propionate 30%, calcium propionate 10%, Tween 10%, Span 10%, polyethylene glycol Alcohol Glyceryl Ricinoleate 10%, Water 10%. The preparation method is as follows:

[0058] (1) each component is weighed by the above-mentioned proportioning;

[0059] (2) Put the components of the antifungal agent into the finished product mixing tank first, stir and mix, add formic acid or sodium hydroxide according to the pH value of the antifungal agent, adjust the pH value of the antifungal agent to 6.0, and mix evenly to obtain antifungal Agent pretreatment solution;

[0060] (3) Add Tween, Span and polyethylene glycol glycerol ricinoleate into the emulsifier pretreatment tank, and add water, stir and mix for 8 minutes to obtain the emulsifier pretreatment liquid;

[0061] (4) Add the emulsifier pretreatment solution obtained in step (3) into the finis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com