Cleanup method for optics in immersion lithography

An optical system and immersion technology, which can be used in cleaning methods, cleaning methods and utensils using liquids, microlithography exposure equipment, etc., which can solve the problems of time-consuming and cumbersome

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

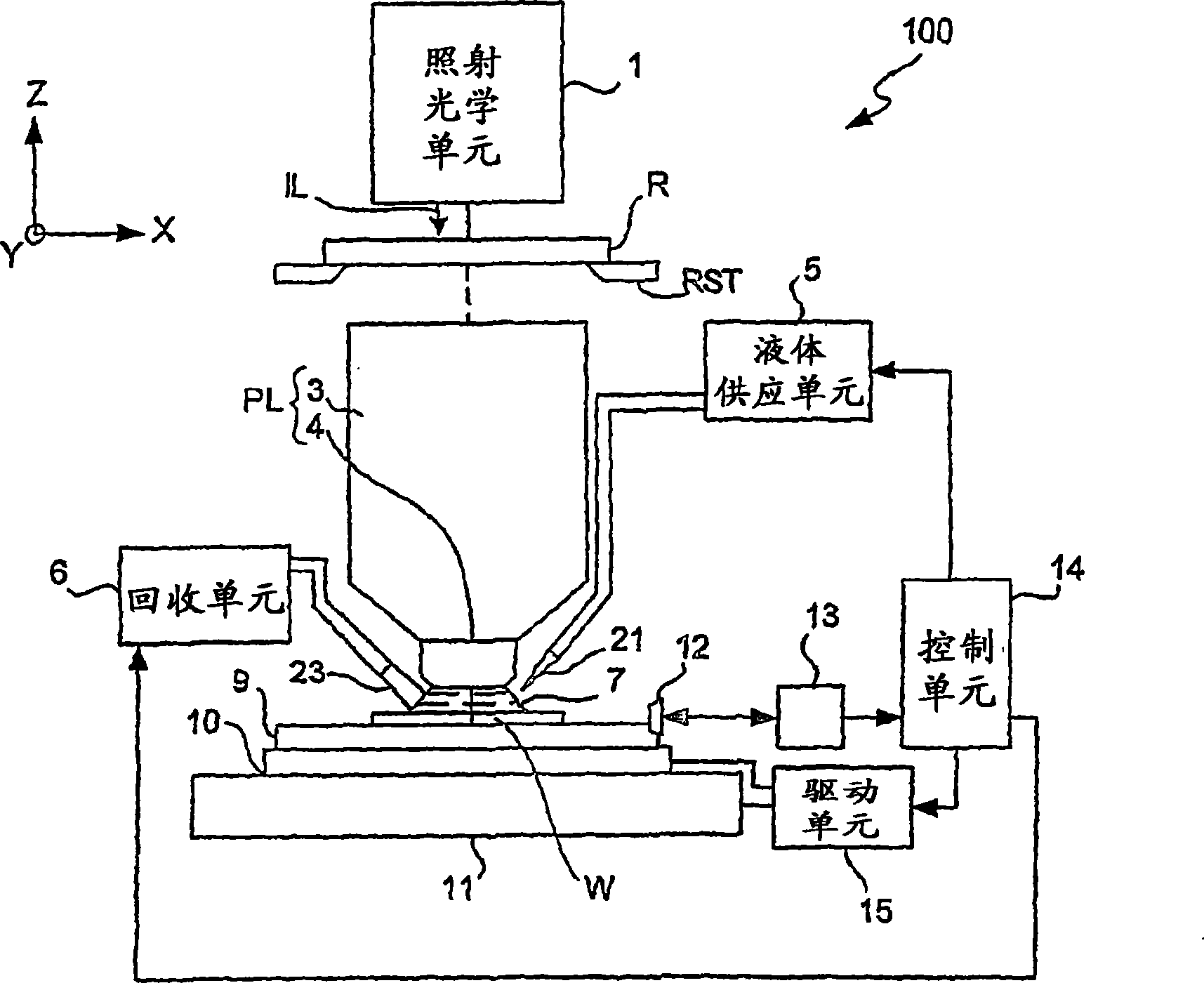

[0029] figure 1 An immersion lithography apparatus 100 is shown on which the method and system of the present invention may be applied.

[0030] Such as figure 1 As shown, the immersion lithography apparatus 100 includes an illumination optics unit 1, which includes a light source such as an excimer laser unit, an optical integrator (or homogenizer) and a lens, and the illumination optics unit is used to emit wavelength The ultraviolet light IL of 248nm is incident on the pattern on the reticle R. The pattern on the reticle R is projected onto the wafer W coated with photoresist at a specified magnification (eg 1 / 4 or 1 / 5) by a telecentric light projection unit PL. Pulsed light IL can be selected from ArF excimer laser with a wavelength of 193nm, and F excimer laser with a wavelength of 157nm 2 Excimer laser light, or mercury lamp i-line with a wavelength of 365nm. Subsequently, when describing the structure and function of the lithography apparatus 100, use figure 1 The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com