Method for producing forage by mulberry branch

A technology of mulberry branches and animal feed, applied in the direction of animal feed, animal feed, additional food elements, etc., can solve the problems of secondary environmental air pollution, difficult to handle, highly polluted mulberry branch production and seasonality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0030] The implementation method of mulberry feed comprises the following steps:

[0031] The required raw material active ingredient of the present invention is big and the weight percent of each component is;

[0032] (1) crushed mulberry branches 50-95%

[0033] (2) Straw powder (mulberry branch substitute) 30-50%

[0034] (3) Rice bran 10-15%

[0035] (4) Urea 3-4%

[0036] (5) Livestock manure (replacing rice bran and urea) 30-70%

[0037] (6) Edible fungi, medium-low temperature aerobic microorganisms, and yeasts are 1-20% of the above-mentioned total proportion.

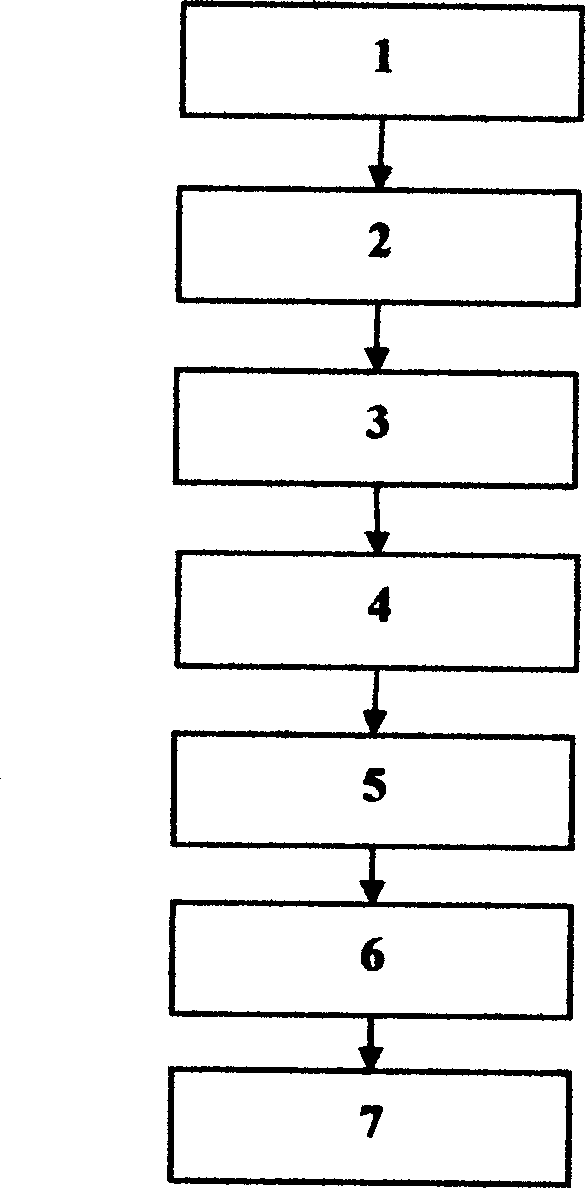

[0038] The process procedure is as follows (attachment 1 in the manual): 1. Raw material crushing → 2. Raw material mixing and puffing → 3. Medium and low temperature aerobic microbial fermentation → 4. Fungal inoculation → 5. Solid fungal hyphae fermentation → 6. Yeast Fermentation → 7. Feed. Each procedure is described separately as follows:

[0039] 1. Crushing of raw materials:

[0040] The mulberr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com