Production technology of glucomannan

A technology of glucomannan and production process, applied in the field of glucomannan preparation, can solve the problems of high processing cost, cumbersome steps, low yield of glucomannan, etc., achieves low cost, avoids the destruction of three-dimensional structure, The effect of maintaining water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

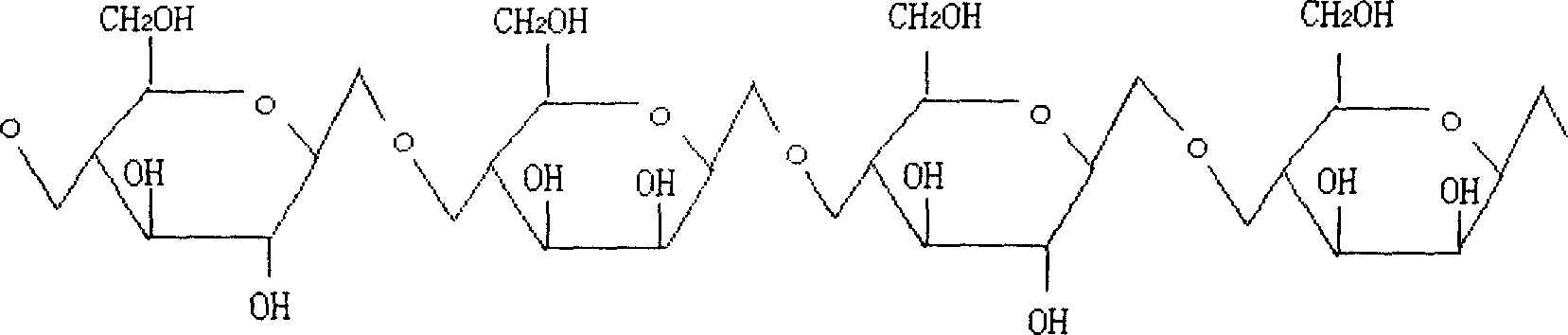

Image

Examples

Embodiment 1

[0019] Example 1 Preparation of the solvent of the present invention

[0020] Mix the monohydric alcohol, ester, and polyhydric alcohol according to the ratio, and the ratio is shown in Table 1:

[0021]

Embodiment 2

[0022] Example 2 Preparation of Glucomannan

[0023] The underground tubers of the Araceae plant Konjac are dried, peeled, sliced, dried, crushed, and sieved to obtain 80-120 mesh konjac powder; soak the konjac powder with solvent, and the mixing ratio: add 2.2 per 1kg konjac powder After liters of solvent, the konjac meal and the solvent are fully mixed, stir at room temperature for 3 hours, and the stirring speed is controlled at 60-100 rpm;

[0024] Centrifugal filtration, the speed of the centrifuge is controlled at 1500-3000 rpm, washed with absolute ethanol 3 times (until the filtrate is clarified), and dried under reduced pressure at 40-60°C to obtain medicinal glucomannan; the obtained preparation results are shown in Table 2 :

[0025]

Solvent number

Yield / %

(As glucomannan / konjac meal)

Contains glucomannan / %

(Calculated as anhydrous glucose)

1

65.8

56.3

2

66.4

66.8

3

75.2

67.5

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com