Plasticizer for biodegradable resin

A biodegradable and plasticizer technology, applied in the field of plasticizers for biodegradable resins and biodegradable resin compositions, can solve problems such as insufficient flexibility, easy whitening, and inability to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

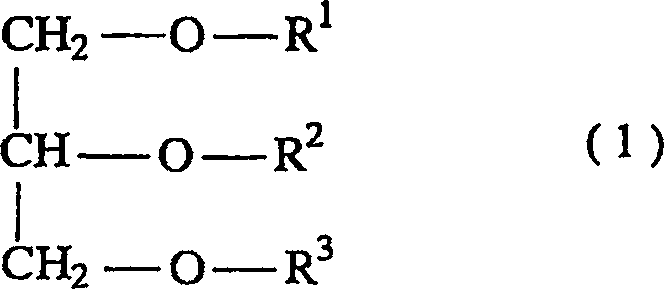

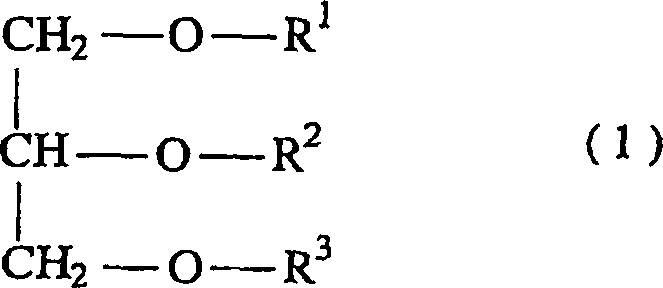

Method used

Image

Examples

Embodiment 1~2 and comparative example 1~3

[0051] As a biodegradable resin, 100 parts by weight of polylactic acid resin (trade name レイイシア (LACEA) H-400 produced by Mitsui Chemicals Co., Ltd.) obtained after vacuum drying at 50°C for 24 hours, and as shown in Table 1 The composition formed by 15 parts by weight of the plasticizer was kneaded for 10 minutes with a laboratory plasticizer (manufactured by Toyo Seiki Co., Ltd.) at 180°C, and then a press molding machine with a thickness of 0.5mm was produced using a press molding machine at 190°C. test piece.

[0052] The prepared test pieces were evaluated for volatility resistance, flexibility, transparency and bleed resistance by the following methods. The results are shown in Table 1.

[0053]

[0054] Using a differential calorimeter, the temperature of the plasticizer was raised from room temperature to 300° C. (5° C. / minute) in a nitrogen atmosphere, and the temperature at which the weight decreased by 10% was measured. The processing temperature of polylactic a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com