Optical data storage media

A media and information technology, applied in the direction of optical record carrier, optical record carrier manufacturing, information storage, etc., can solve the problems of lack of structure and inconvenience of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

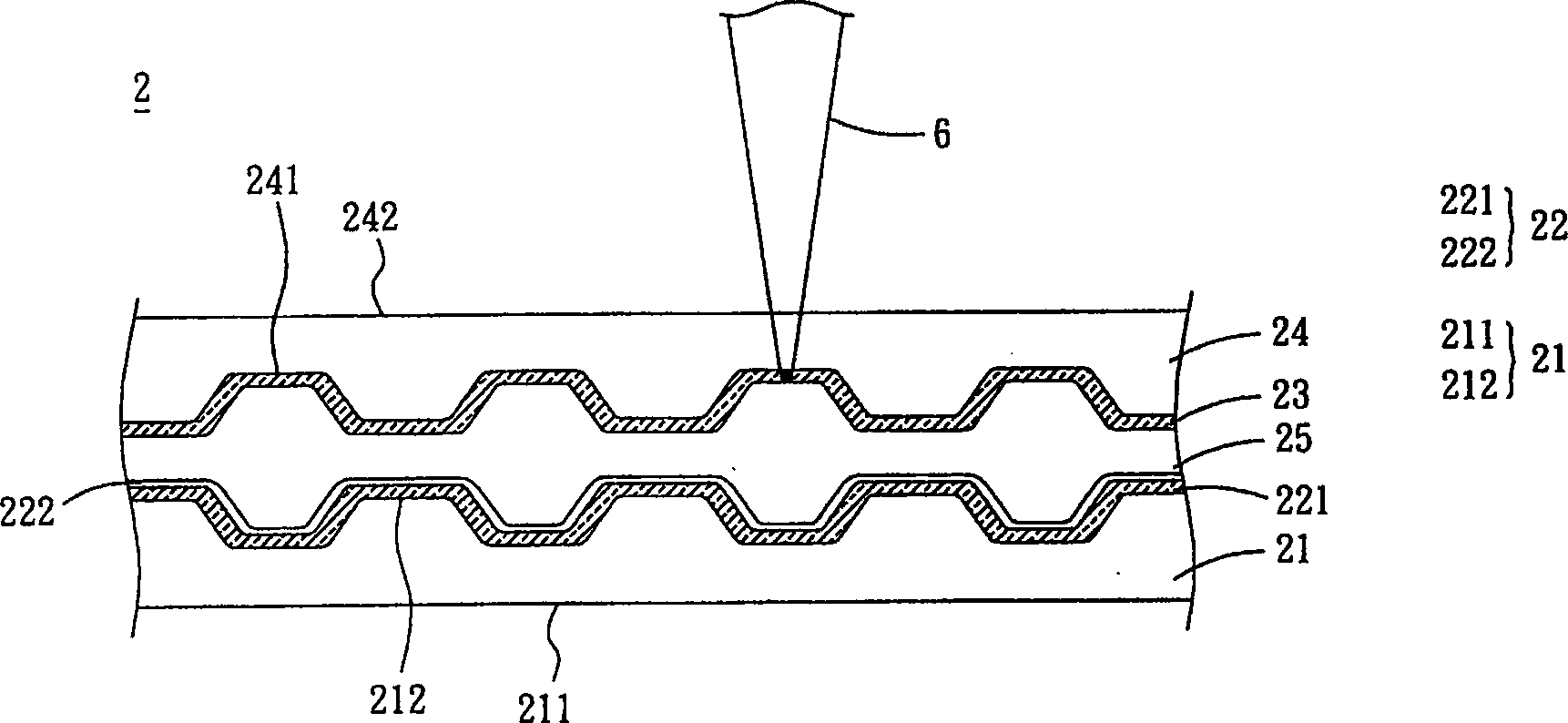

[0048] Please refer to figure 2 As shown, the optical information storage medium 2 according to the first embodiment of the present invention includes a first substrate 21 , at least one recording layer 22 , a first drawing layer 23 and a second substrate 24 .

[0049] The first substrate 21 has a first surface 211 and a second surface 212 ; the recording build-up layer 22 is disposed on the second surface 212 of the first substrate 21 . In this embodiment, the recording layer 22 includes a recording layer 221 and a reflective layer 222 , and the reflective layer 222 is disposed on the recording layer 221 .

[0050] The first drawing layer 23 is disposed on the recording layer 22, and its material is to have a phase change material or an organic dye, wherein the phase change material is, for example, Ge-Sb-Te or Ag-In-Sb-Te, etc., After being irradiated by a laser beam 6, the phase change material undergoes a phase change due to the high temperature generated by the focusing...

no. 2 example

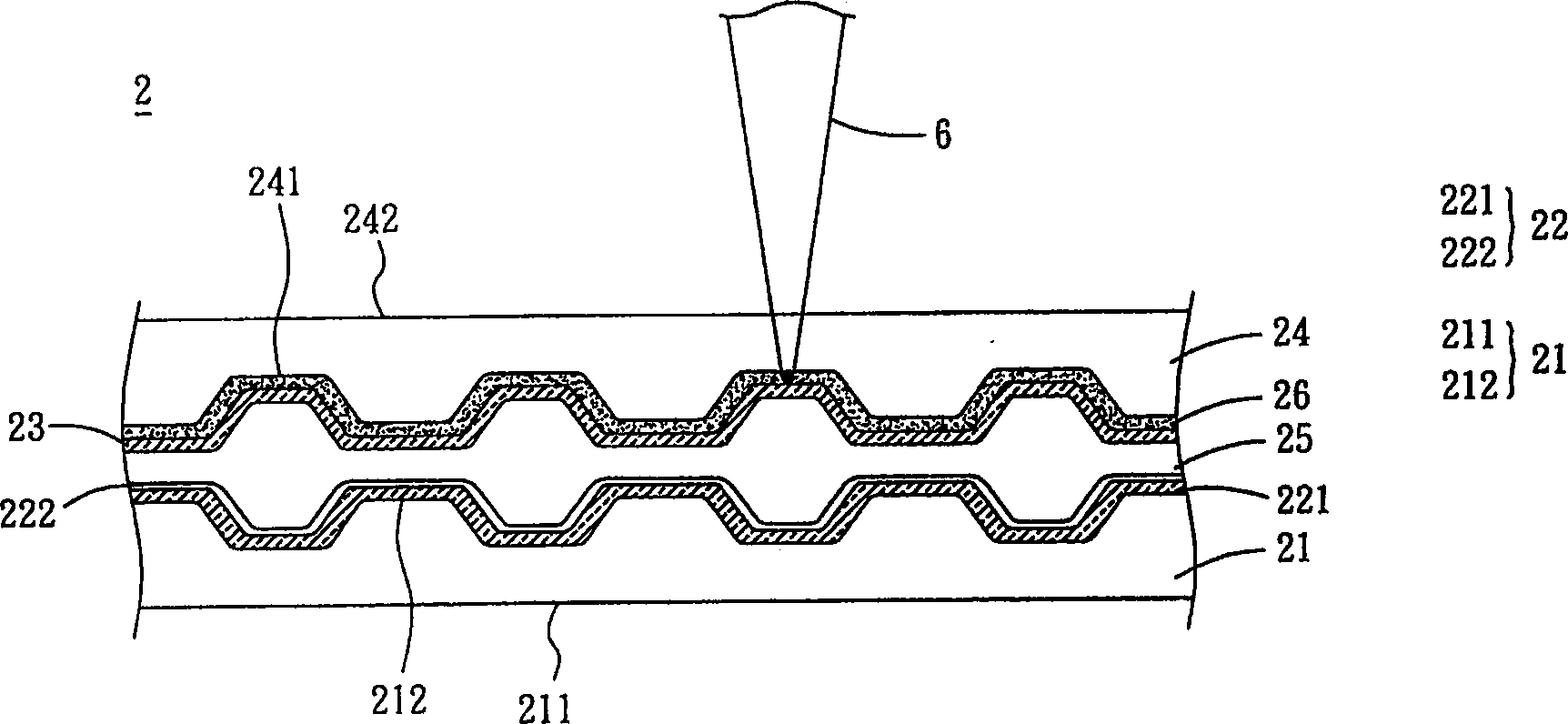

[0054] Please refer to image 3 As shown, the optical information storage medium 2 of the second embodiment of the present invention includes a first substrate 21 , at least one recording layer 22 , a first drawing layer 23 , a second drawing layer 26 and a second substrate 24 .

[0055] The structures, materials and features of the first substrate 21 , the recording layer 22 , the first drawing layer 23 and the second substrate 24 in this embodiment are the same as those described in the first embodiment, so they will not be repeated here.

[0056] However, in this embodiment, the second drawing layer 26 is disposed on the first drawing layer 23 . Here, for example, the material of the first drawing layer 23 can be green titanium cyanine dye, and the second drawing layer 26 can be a red nitrogen-containing compound. After the light beam 6 is irradiated, a pit will be formed to expose the color of the first drawing layer 23, and because the second substrate 24 is transparent,...

no. 3 example

[0058] Please refer to Figure 4 As shown, the optical information storage medium 2 of the third embodiment of the present invention includes a first substrate 21, at least one recording layer 22, a first drawing layer 23, a second drawing layer 26, a third drawing layer 27 and A second substrate 24 .

[0059] The structures, materials and features of the first substrate 21, recording layer 22, first drawing layer 23, second drawing layer 26, and second substrate 24 of this embodiment are as described in the second embodiment, so they will not be repeated here. repeat.

[0060] However, in this embodiment, the third drawing layer 27 is disposed between the first drawing layer 23 and the second drawing layer 26 . For example, the material of the first drawing layer 23 can be green titanium cyanine dye, the second drawing layer 26 can be red nitrogen-containing compound, and the third drawing layer 27 can be selected from blue cyanine dye. By modulating the intensity of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com