Punch-shearing machine

A stamping shearing and frame technology, which is applied in the direction of shearing devices, nibbling cutting devices, shearing equipment, etc., can solve the problems of laborious operation, incompetent processing, and lengthy processing process without contamination of metal shavings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

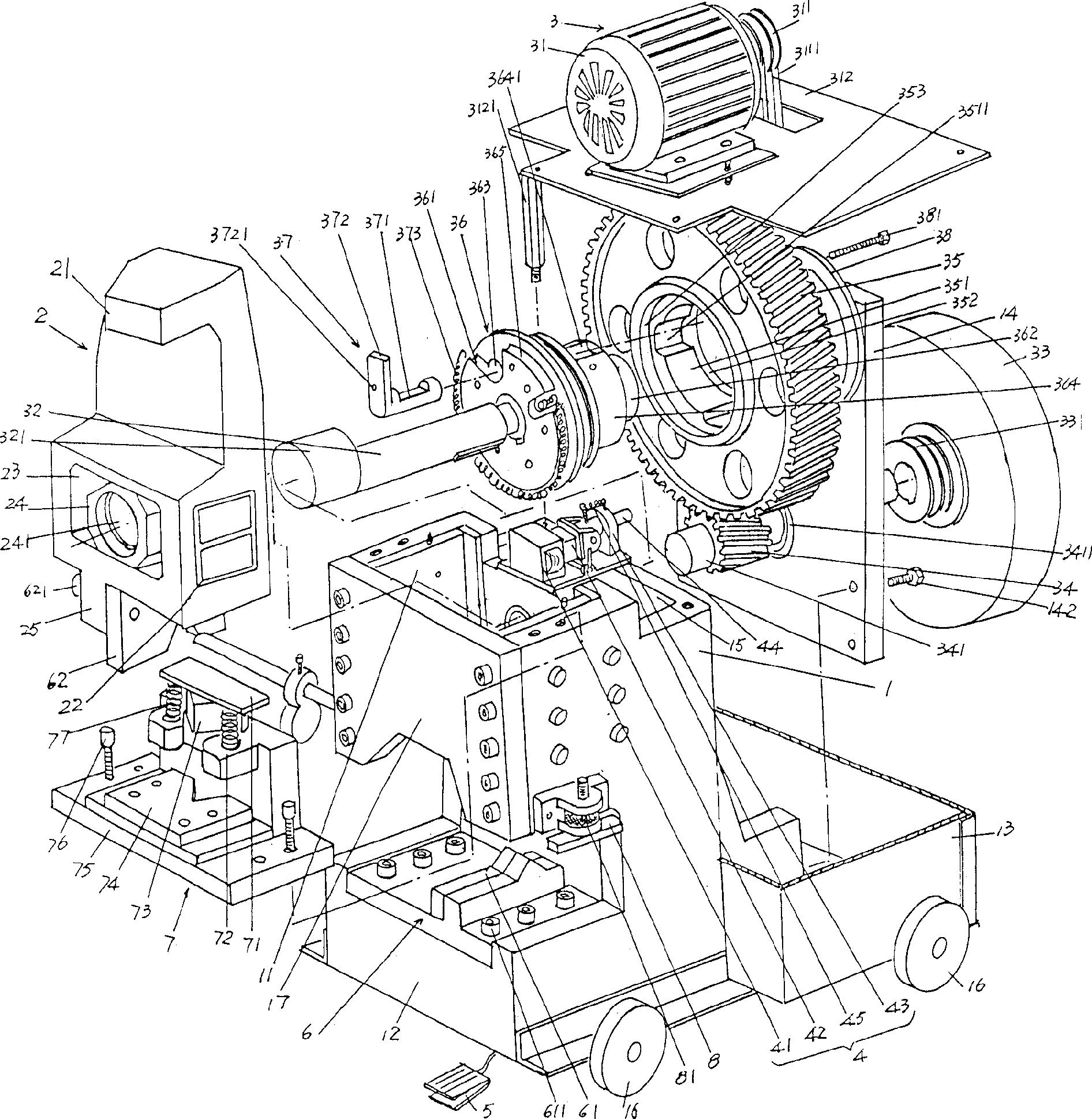

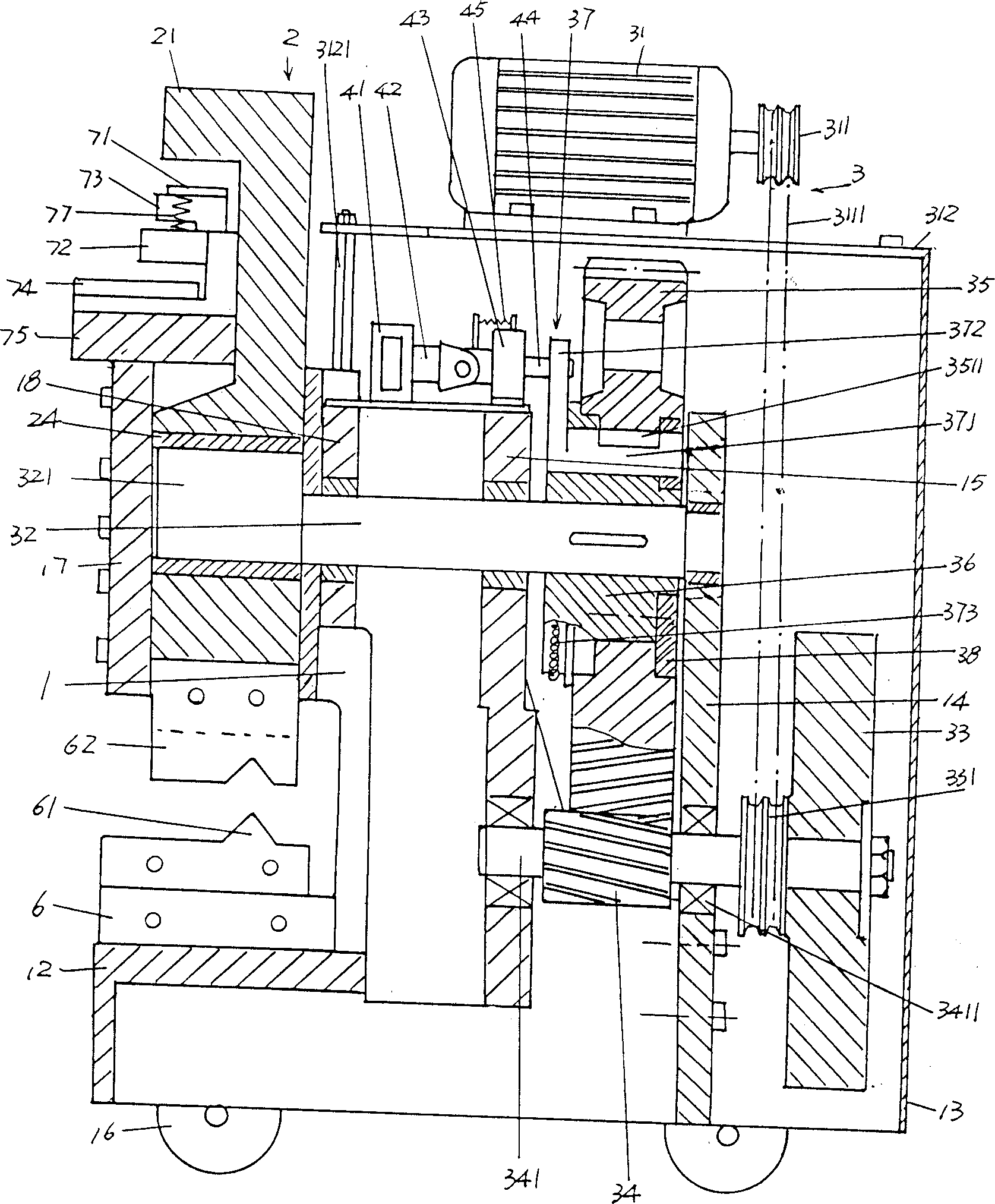

[0018] please see figure 1 and combine figure 2 , the upper front side of the frame 1 is processed with a slider cavity 11, the front side mentioned here refers to the side facing the operator in use, the cavity of the slider cavity 11 is the third wall plate 17 shields, a certain distance is reserved between the third wall plate 17 and the blanking mold base 12, and the working area is formed by this distance. The punch slider 2 is accommodated in the cavity area of the slider cavity 11. In order to obtain a good lubrication effect between the two sides of the punch slider 2 and the two inner walls of the slider cavity 11, it can be recessed in the punch The oil channels 22 on the lower part of both sides of the slide block 2 replenish lubricating oil, so that the up and down movement of the punch slide block 2 is flexible. The sliding sleeve 24 arranged in the sliding sleeve hole 23 at the lower part of the punch slider 2 is connected with the transmission mechanism 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com