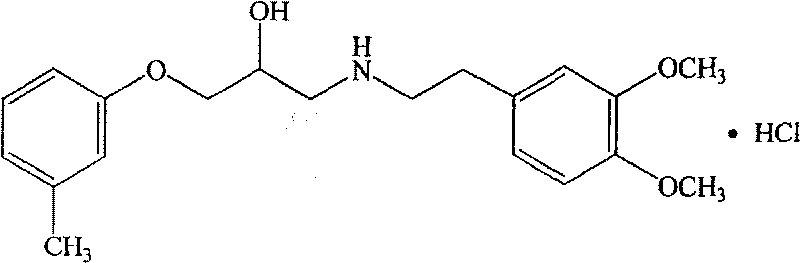

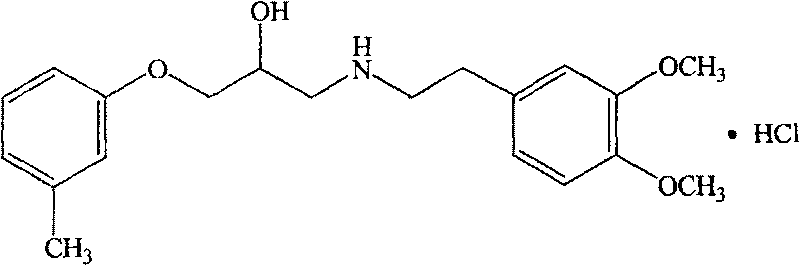

Method for refining bevantolol hydrochloride

A technology of bevanolol hydrochloride and a refining method, which is applied in the refining field of bevanolol hydrochloride, can solve the problems of increasing solvent post-processing work, increasing product cost, difficult to remove inorganic salts, etc., so as to simplify operations and reduce the number of refining times. , The effect of controlling the content of inorganic salts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

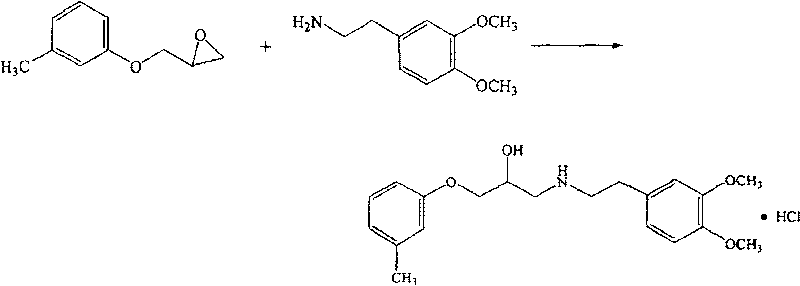

Method used

Image

Examples

Embodiment 1

[0017] Add 150ml of distilled water and 50g of crude bevanolol hydrochloride to the reaction flask, reflux to dissolve the solid, heat filter, and cool the filtrate to crystallize. Suction filtration, drying to constant weight, white solid powder: 46g, yield: 92%, purity: 99.82% (HPLC), residue on ignition: 0.012%.

Embodiment 2

[0019] Add 2250ml of 5% isopropanol aqueous solution and 300g of crude product of bevanolol hydrochloride to the reaction flask, reflux to dissolve the solid, heat filter, and the filtrate is cooled and crystallized. Suction filtration, drying to constant weight, white solid powder: 282g, yield: 94%, purity: 99.81% (HPLC), residue on ignition: 0.010%.

Embodiment 3

[0021] Add 550 ml of 95% isopropanol aqueous solution and 100 g of crude bevanolol hydrochloride to the reaction flask, reflux to dissolve the solid, heat filter, and the filtrate is cooled and crystallized. Suction filtration and drying to constant weight gave white solid powder: 95g, yield: 95%, purity: 99.80% (HPLC), residue on ignition: 0.013%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com