Zooming apparatus of long-distance large-range semiconductor laser lighting device

A semiconductor, a wide range of technology, used in semiconductor lasers, lasers, laser parts and other directions, can solve the problems of high cost, unfavorable installation, energy waste, etc., to achieve the effect of low cost, simple implementation and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

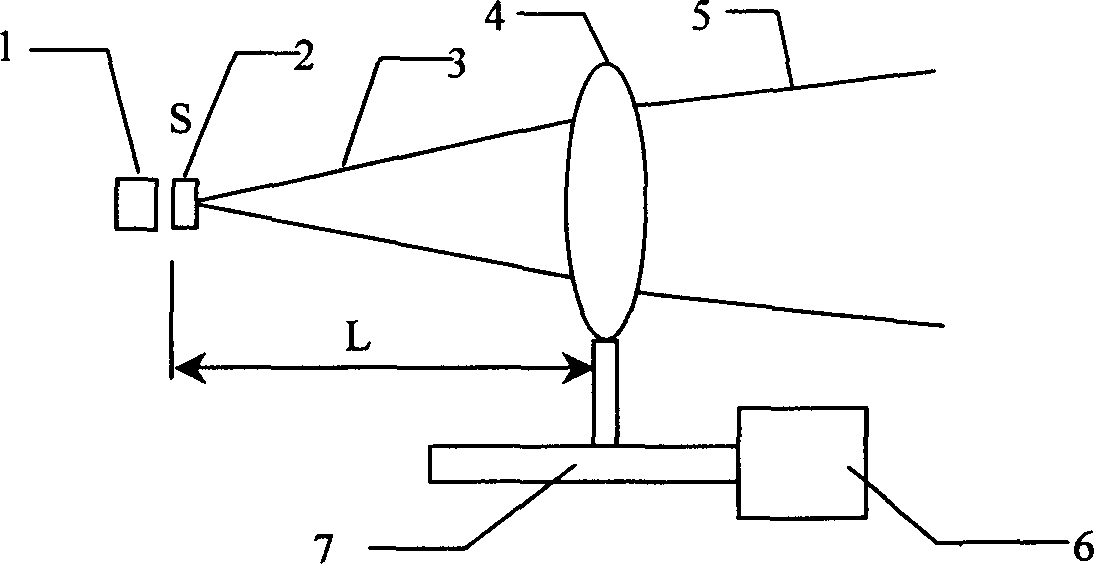

[0028] Such as figure 1 As shown, the beam emitted by the semiconductor laser 1 is usually about 10° (horizontal) × 40° (vertical), and the horizontal and vertical divergence angles are adjusted to be basically the same through the shaping optical device 2 . After shaping, the light beam 3 is angle-compressed by the thin lens group 4 with positive refractive power, and emerges as the outgoing light beam 5. The angle of the outgoing light is related to the distance L, and L is the distance between the light source s and the thin lens group 4 . The motor 6 converts the rotational motion into a linear motion through the mechanical transmission mechanism 7, drives the lens 4 to move back and forth, and adjusts the distance L, thereby controlling the outgoing angle of the outgoing light beam 5. During the forward and backward movement of the thin lens group 4, it is always ensured that the light source S is located on the optical axis of the thin lens group 4, and the entire optic...

Embodiment 2

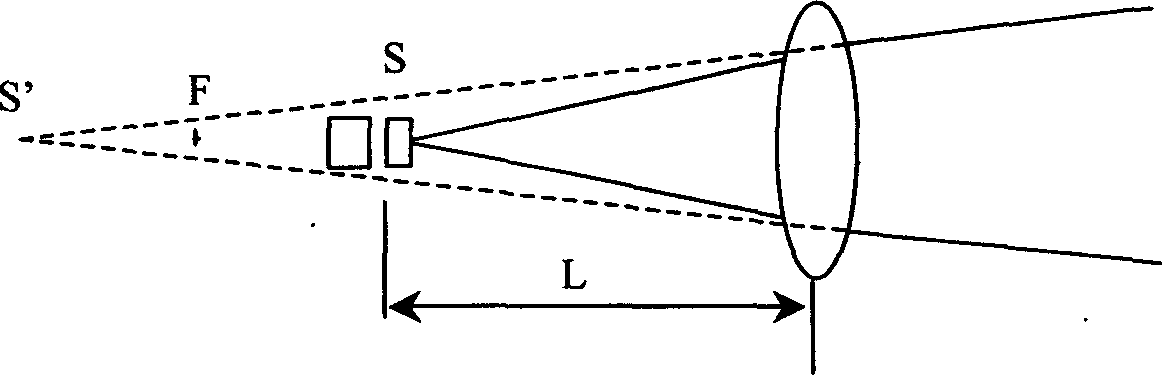

[0030] The angle of the outgoing beam is determined by the divergence angle θ of the light source S after shaping, the focal length f of the lens, and the distance L between the lens and the light source. Such as figure 2 As shown, in particular, the light source S is located within the front focal point F of the lens, and becomes a virtual image light source S' after passing through the lens, and the angle of the outgoing beam is the divergence angle θ' of the light source S'.

Embodiment 3

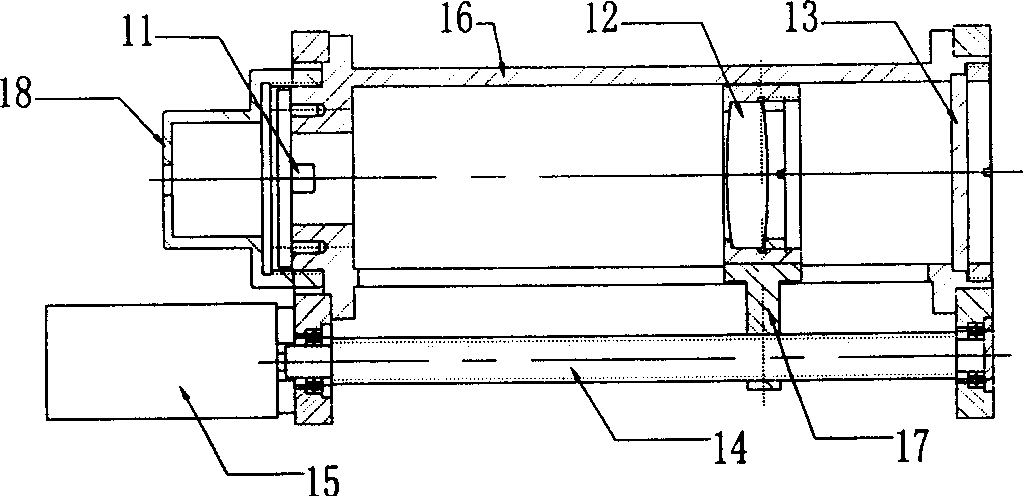

[0032] image 3 It is a specific embodiment of the present invention. The semiconductor laser 1 of this embodiment is fixed on the inner rear end of the lens sleeve 16 by screws, the semiconductor laser 1 itself has been shaped, and the divergence angle is 30°. The double cemented spherical lens 12 has a focal length of 30 mm and a relative aperture of 0.5. It is located inside the lens sleeve 16 and can slide forward and backward therein. The sliding distance is equal to the length of the lens sleeve 16 . The filter protection glass 13 is fixed on the front end of the lens sleeve 16 through a pressure ring. The transmission screw 14 is fixed on the bottom of the lens sleeve 16 through a ball bearing, the right end is connected with the 12V DC motor 15, and the middle is connected with the fixed frame of the doublet lens 12 through the connecting piece 17. The laser protective cover 18 is fixed outside the rear end of the lens sleeve 16 .

[0033] During work, the power lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com