Domestic direct-firing gasification stove

A direct-fired, gasifier technology, used in household stoves/stoves, solid heating fuels, lighting and heating equipment, etc., can solve problems such as high use and maintenance costs, inability to popularize in a large area, and unresolved technology. Low cost, solve common cooking and heating energy, high temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with drawings and embodiments.

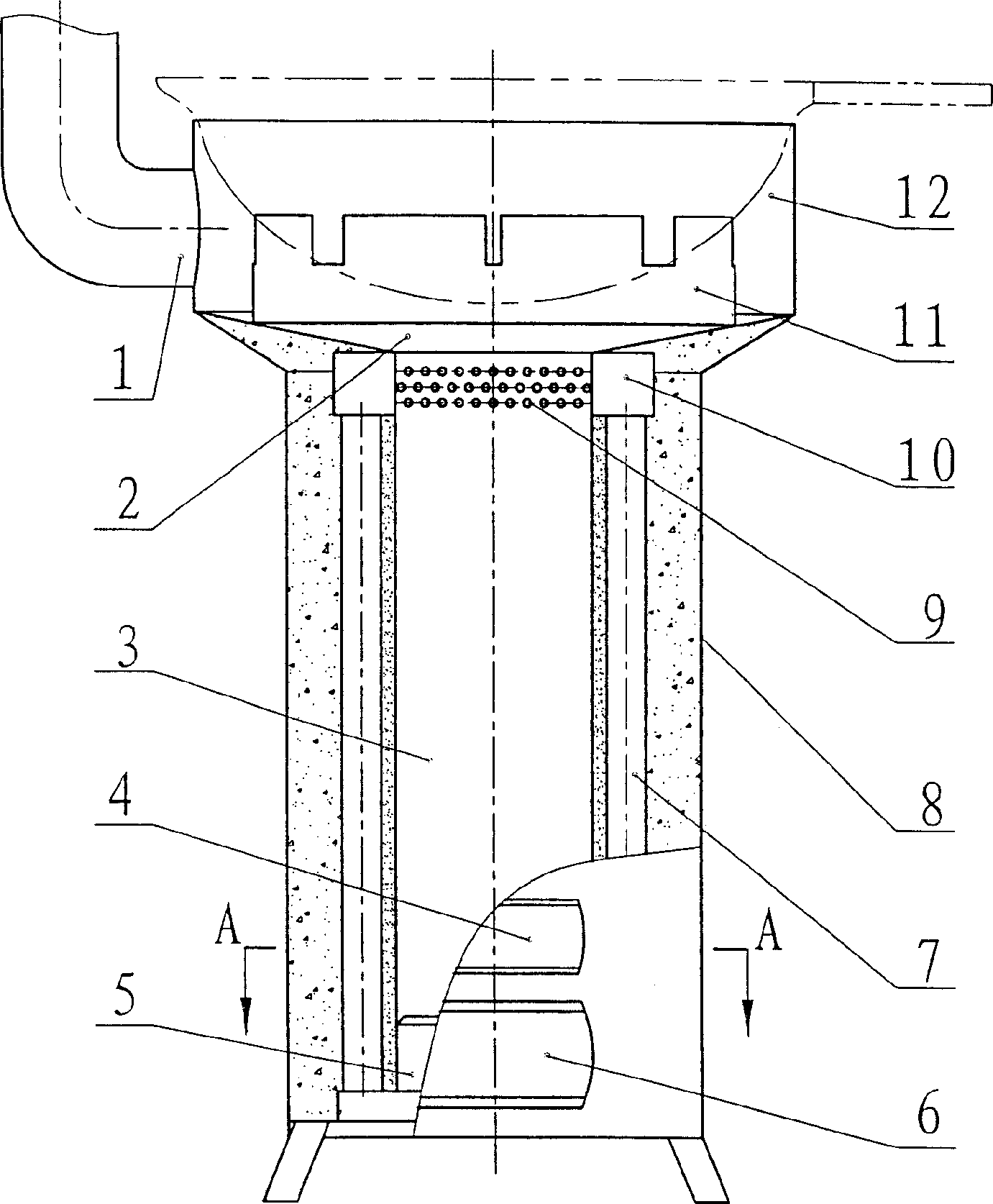

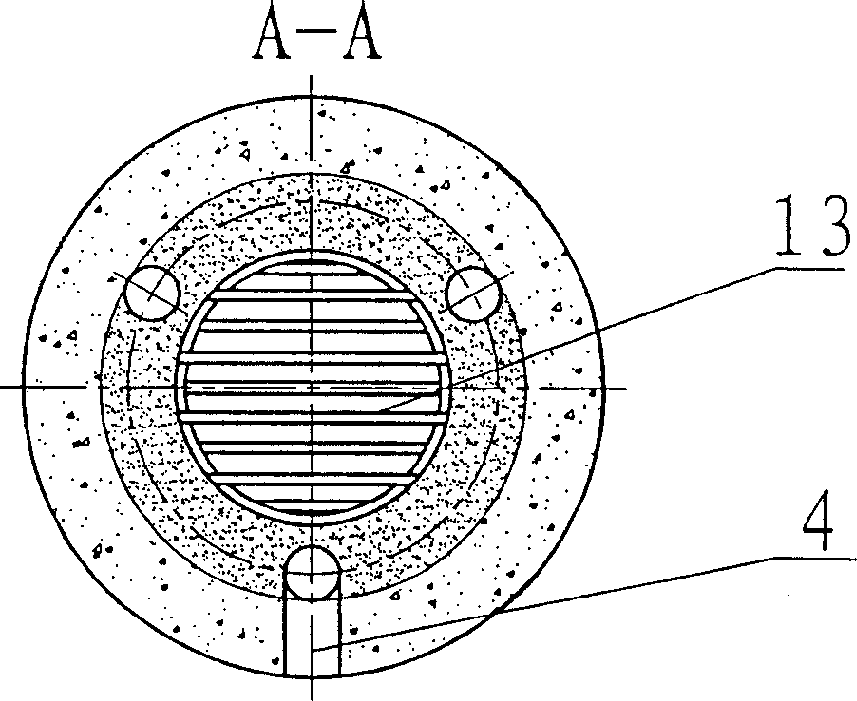

[0018] Such as figure 1 , figure 2 As shown, the present invention includes a furnace body 8, a furnace core 3, a secondary air chamber 10, a secondary air inlet pipe 7, a fire retaining ring 11, a return flue 12, a chimney 1, and the like. There are inner and outer heat insulation layers inside the cavity of the furnace body 8, the outer heat insulation layer is filled with plant ash, and the inner heat insulation layer is filled with expanded perlite for heat preservation. Three evenly distributed secondary air intake vent pipes 7 are built between the inner and outer heat insulation layers, and the gas in the three vent pipes communicates through the cylindrical holes at the bottom of the furnace body 8 . One side of the body of furnace 8 is provided with a secondary air inlet 4 and a primary air inlet 6, the primary air inlet 6 communicates with the ash bin 5, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com