Self-flowing pellet fuel environmental protection stove

A granular fuel and self-flowing technology, which is applied in solid heating fuel, household stove/stove, lighting and heating equipment, etc., can solve the problems of inconvenient fuel versatility, difficult to guarantee environmental protection indicators, poor combustion stability, etc., and achieve good heating effect , avoid high temperature slagging problem, the effect of stable ash layer thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

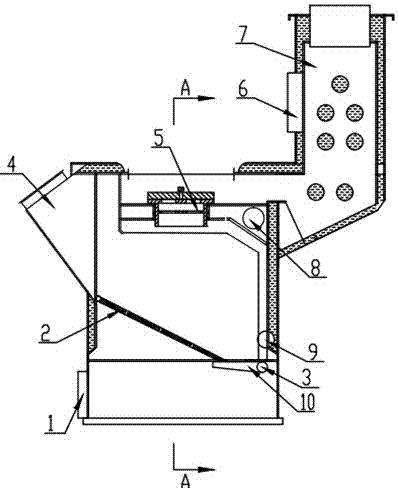

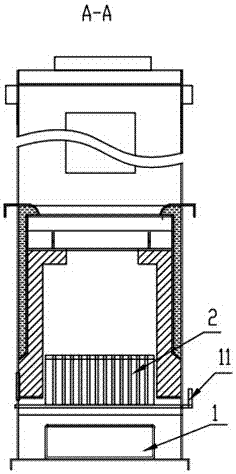

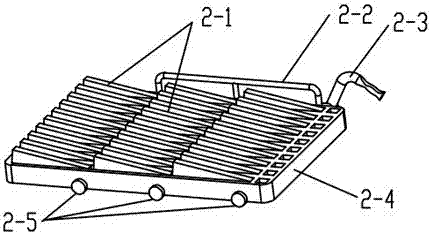

[0034] According to attached figure 1 and 2 It can be seen that the present invention specifically relates to a self-flowing granular fuel environmental protection stove, which specifically includes a furnace body, a feed port located on one side of the furnace body, and The smoke exhaust channel 7 is provided with a combustion chamber inside the furnace body, the upper part of the combustion chamber is the furnace mouth, and the lower part of the combustion chamber is the ash removal chamber. The present invention is an improvement on the basis of traditional stoves. The main improvements are: a movable grate 2 is provided between the combustion chamber and the ash removal chamber, and the movable grate 2 separates the combustion chamber and the ash removal chamber. The grate 2 is placed obliquely inside the furnace body. One end of the movable grate 2 is set at the intersection of the combustion chamber and the feed port 4, and is hinged with the inner wall of the combustio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com