Performance tester based on heat exchanger fin unit

A test device and heat exchanger technology, which is applied in the field of test devices and performance test devices based on heat exchanger fin units, can solve problems such as uneven flow, and achieve the effects of avoiding measurement errors, low processing costs, and high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation of the present invention will be described below with reference to the accompanying drawings.

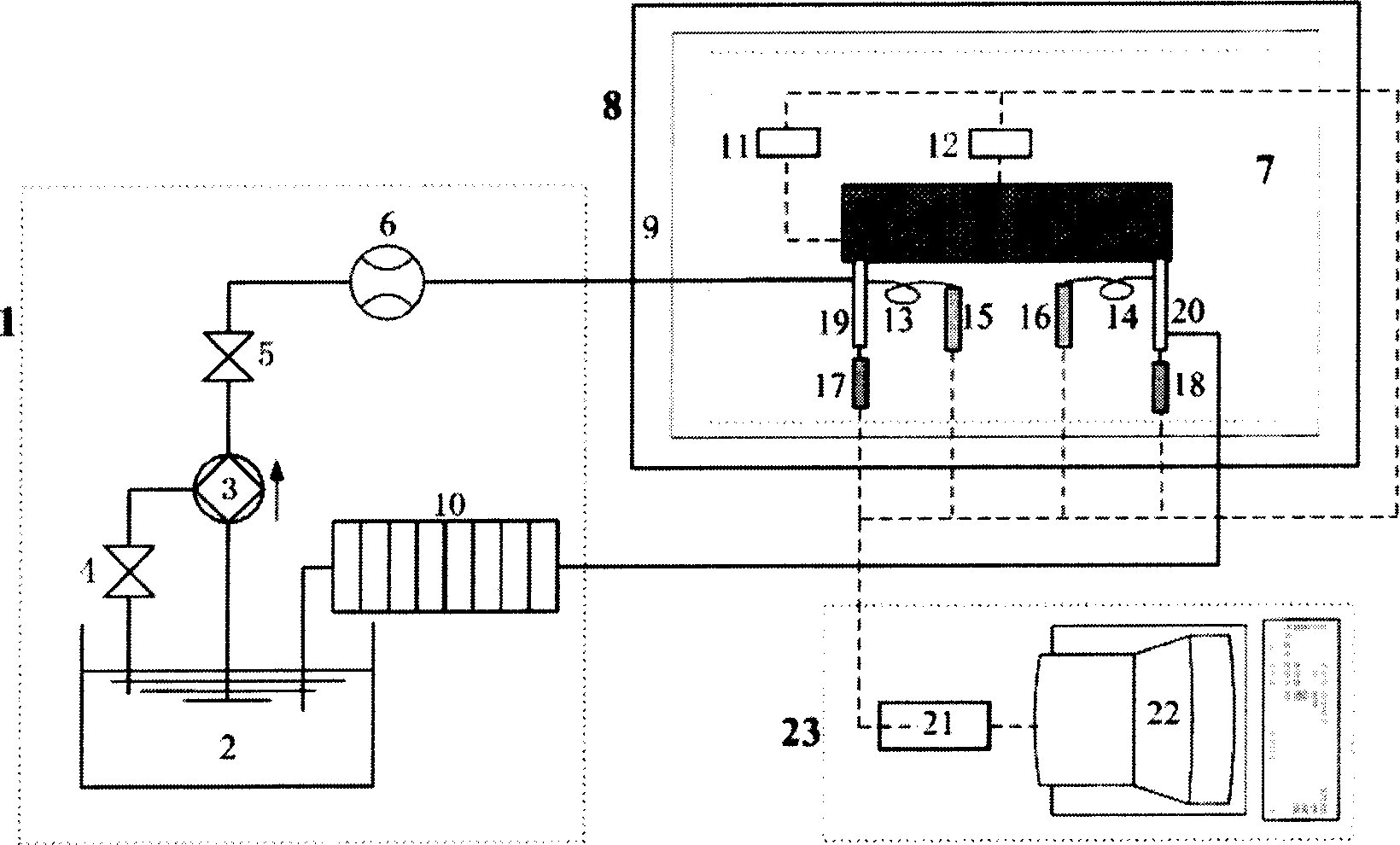

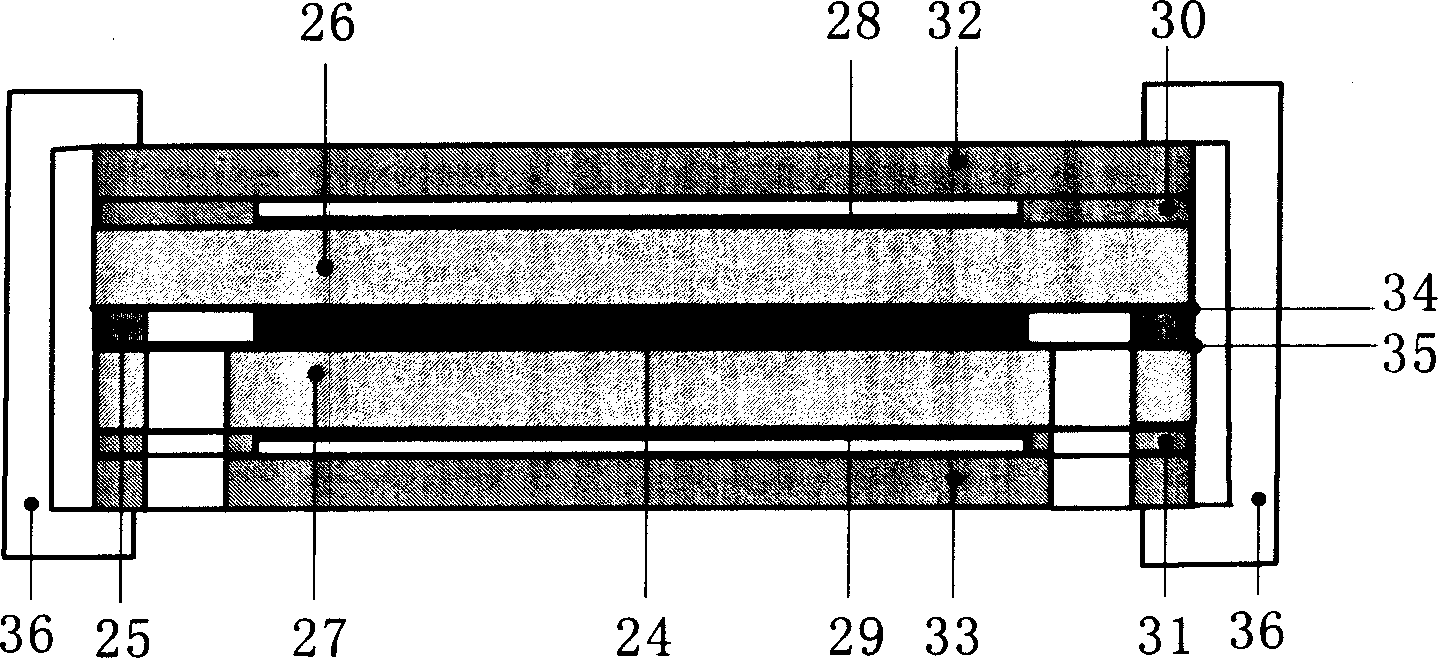

[0018] Such as figure 1 , 2 As shown, the present invention consists of an oil pipeline system 1, a constant temperature oil bath 2, a test section 7, a heat preservation water tank 8 and a data test / acquisition system 23. The oil pipeline system 1 includes a gear oil pump 3, a first pipeline regulating valve 4, a second pipeline regulating valve 5, a mass flow meter 6 and a plate heat exchanger 10; the test section 7 includes a test fin 24 and a fin Frame 25, first copper substrate 26, second copper substrate 27, first thin film heater 28, second thin film heater 29, first thermal insulation frame 30, second thermal insulation frame 31, first thermal insulation plate 32, second thermal insulation Plate 33, first gasket 34, second gasket 35, clamp 36, oil inlet pipe 19, oil outlet pipe 20, thermocouple 12, inlet platinum resistance 17, outlet platinum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com