Three-phasefluidized turbulent ball gas washing tower

A gas scrubber, three-phase flow technology, applied in chemical instruments and methods, dispersed particle separation, use of liquid separation agents, etc., can solve problems such as large operating resistance, high energy consumption, blockage, etc. low consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

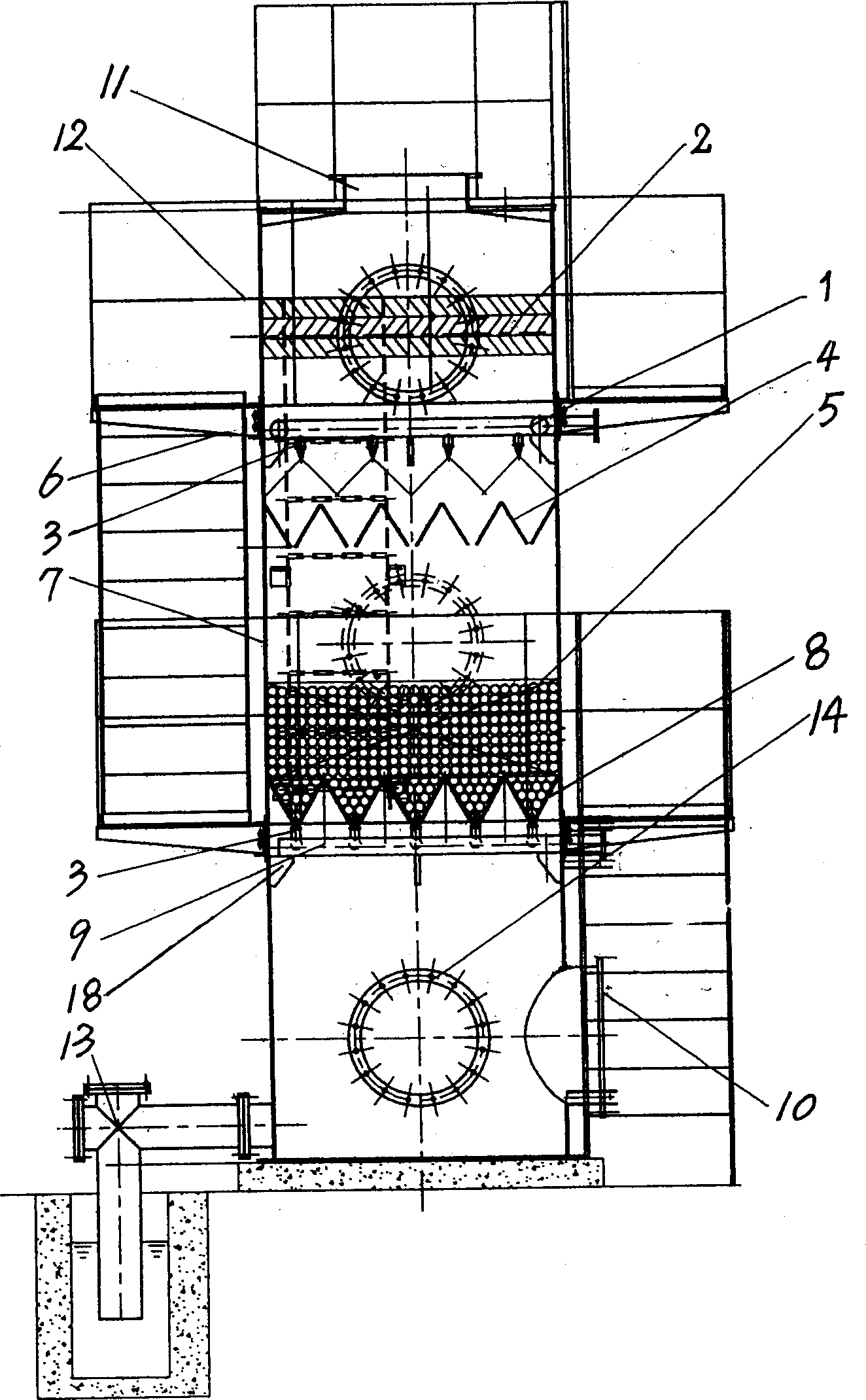

[0014] The embodiments of the present invention will be further described in conjunction with the accompanying drawings. This embodiment is used to illustrate the present invention, but not to limit the present invention.

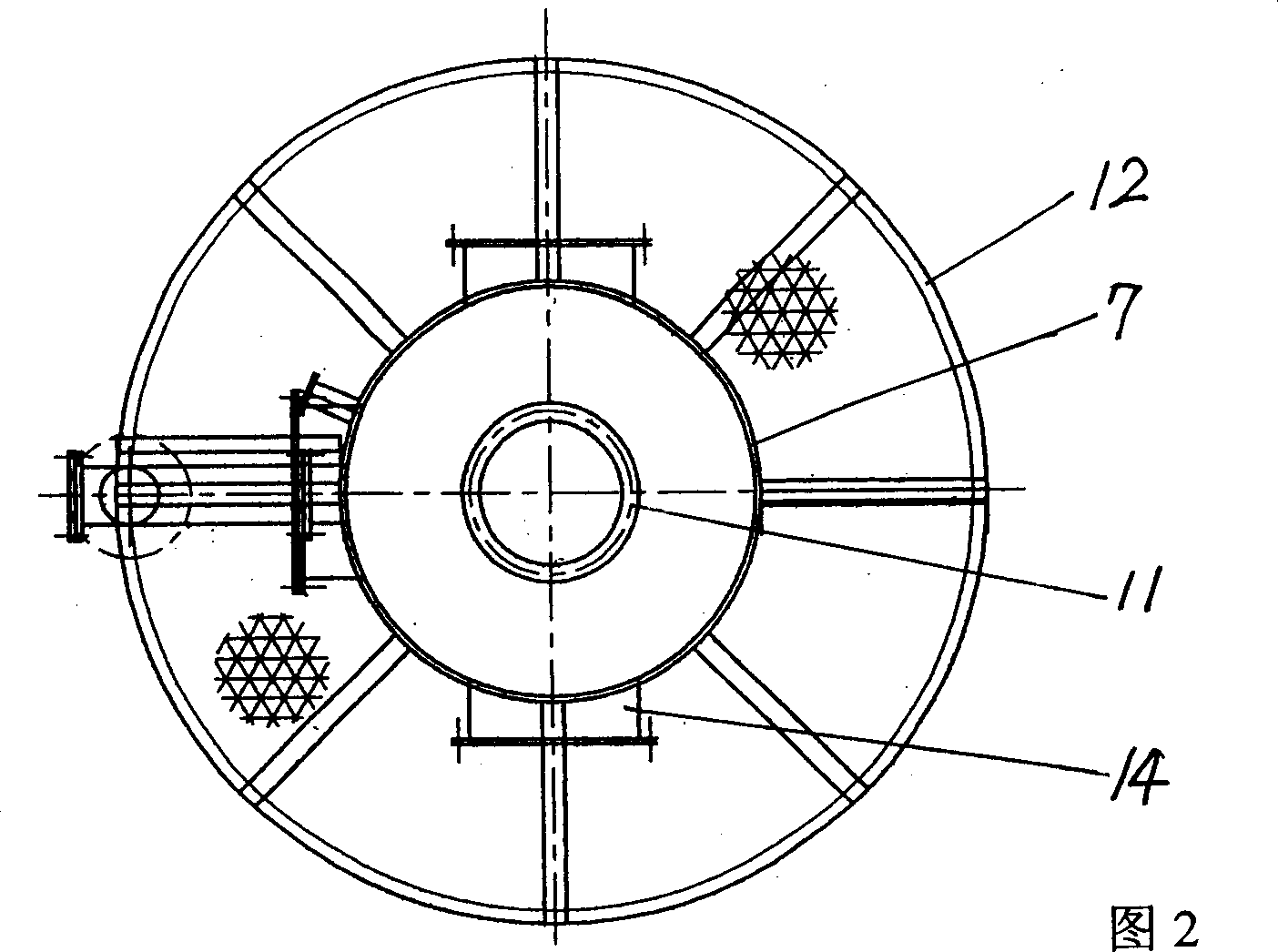

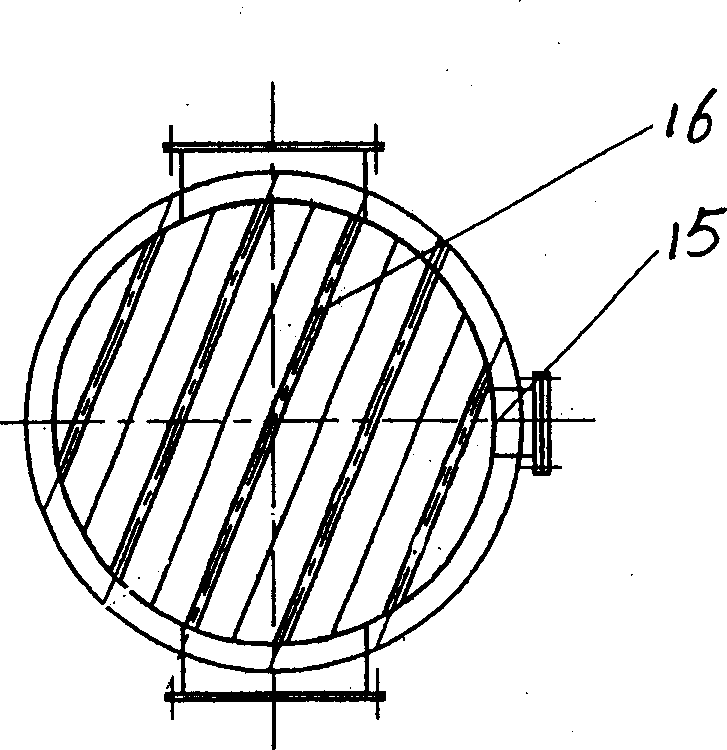

[0015] The three-phase fluidized turbulent ball scrubber includes a housing 7 with an air inlet 10 at the lower part and an exhaust port 11 at the upper part, an escalator 6 fixed to the housing 7, an operating platform 12, and a water return pipe connected to the lower part of the housing 7 13. Inside the shell 7, baffle plate water collector 2, upper air distribution plate 4, upper water spray system 1 with sprinkler 3 at the lower part, turbulent ball packing layer 5, lower air distribution plate 8, and sprinkler head are installed in sequence from top to bottom inside the shell 7 3. Lower sprinkler system 9. The air distribution plate is porous and wavy. There are gaps at the ends of two adjacent air distribution plates at the trough, and a number of d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com