Laser cutter for liquid-crystal screen short-circuit loop

A technology of laser cutting and short-circuit ring, applied in the field of machinery, can solve the problems of low production efficiency and slow cutting speed, and achieve the effect of improving production efficiency, improving cutting and forming speed, and being easy to master and adjust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

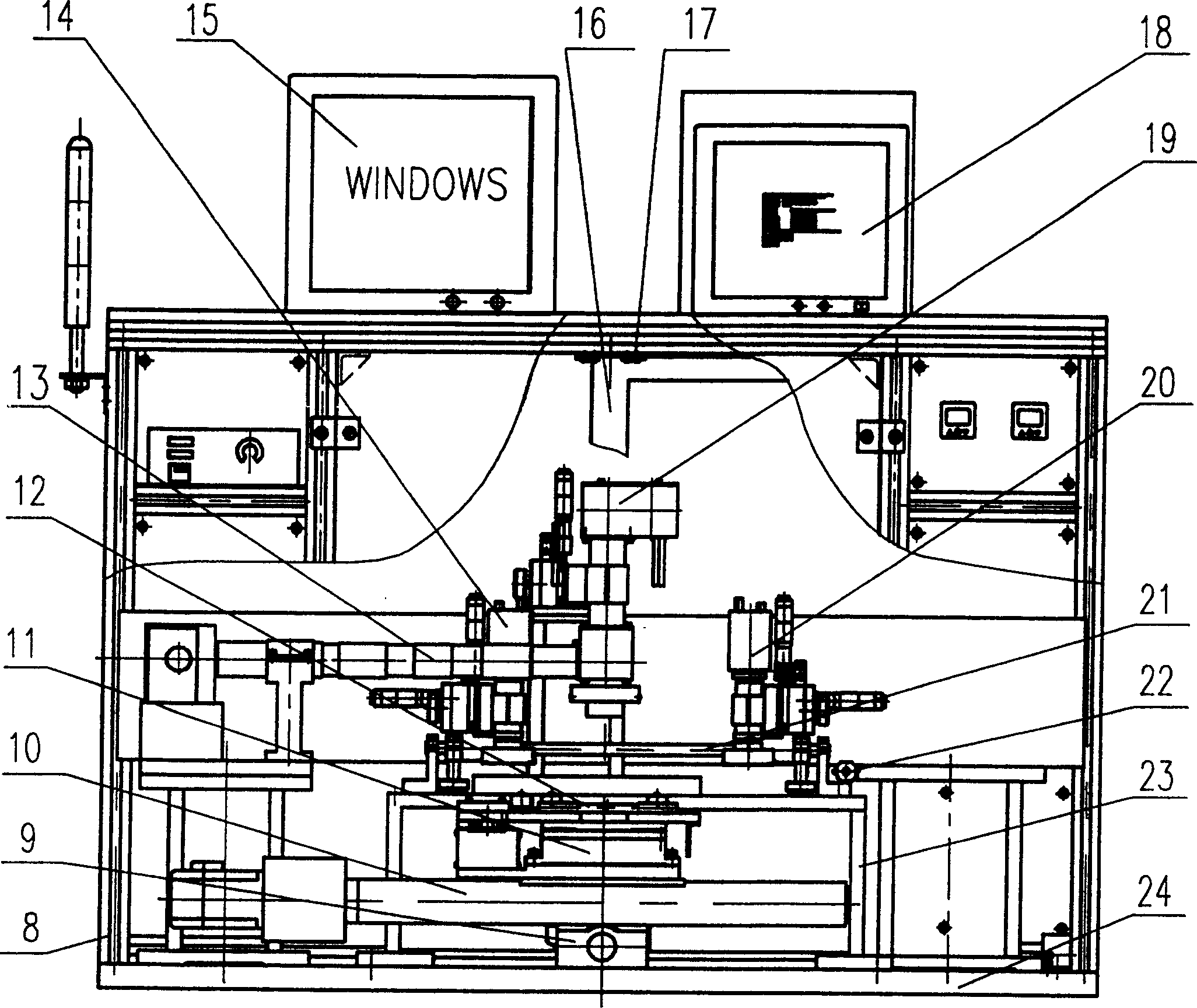

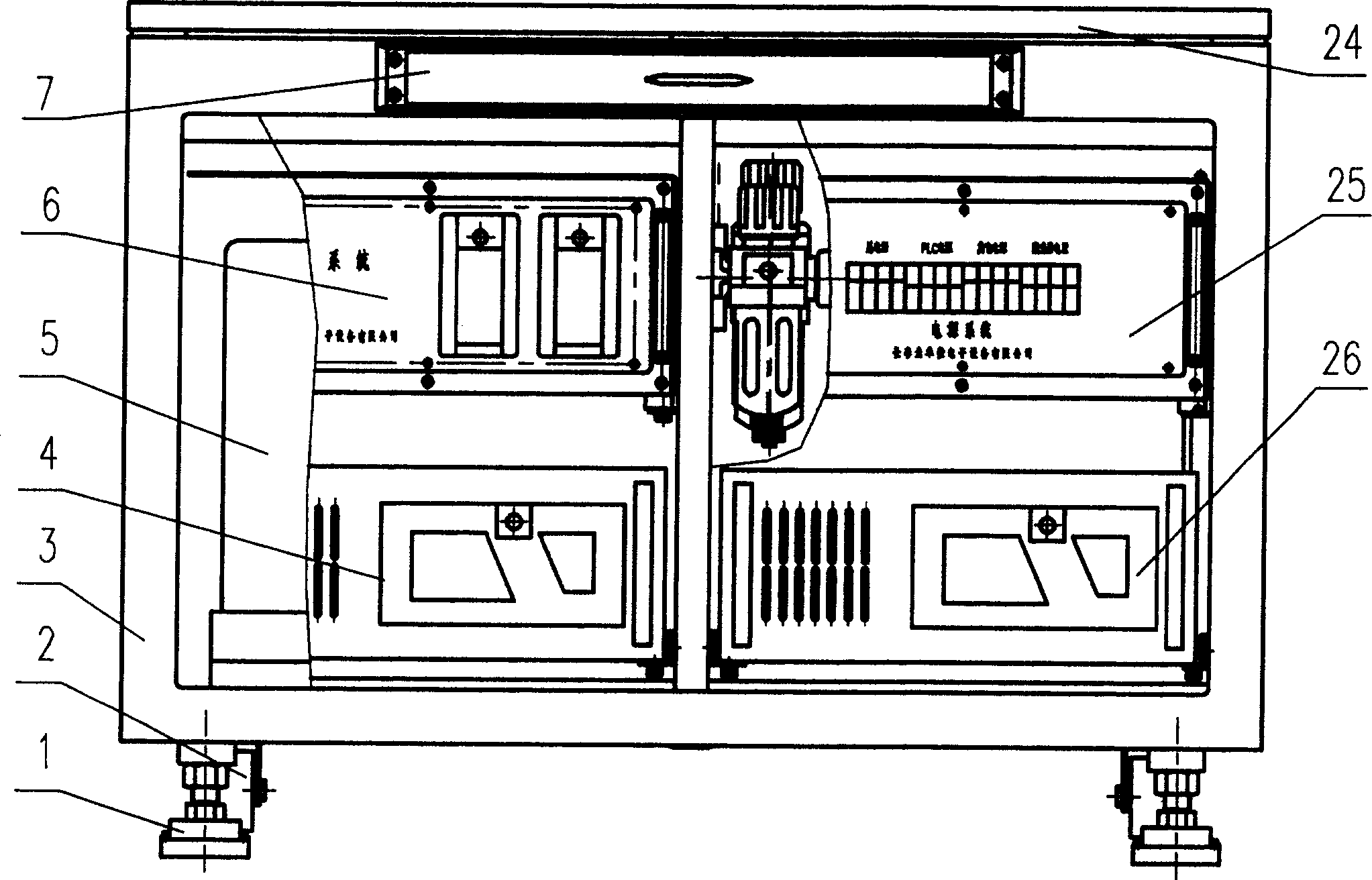

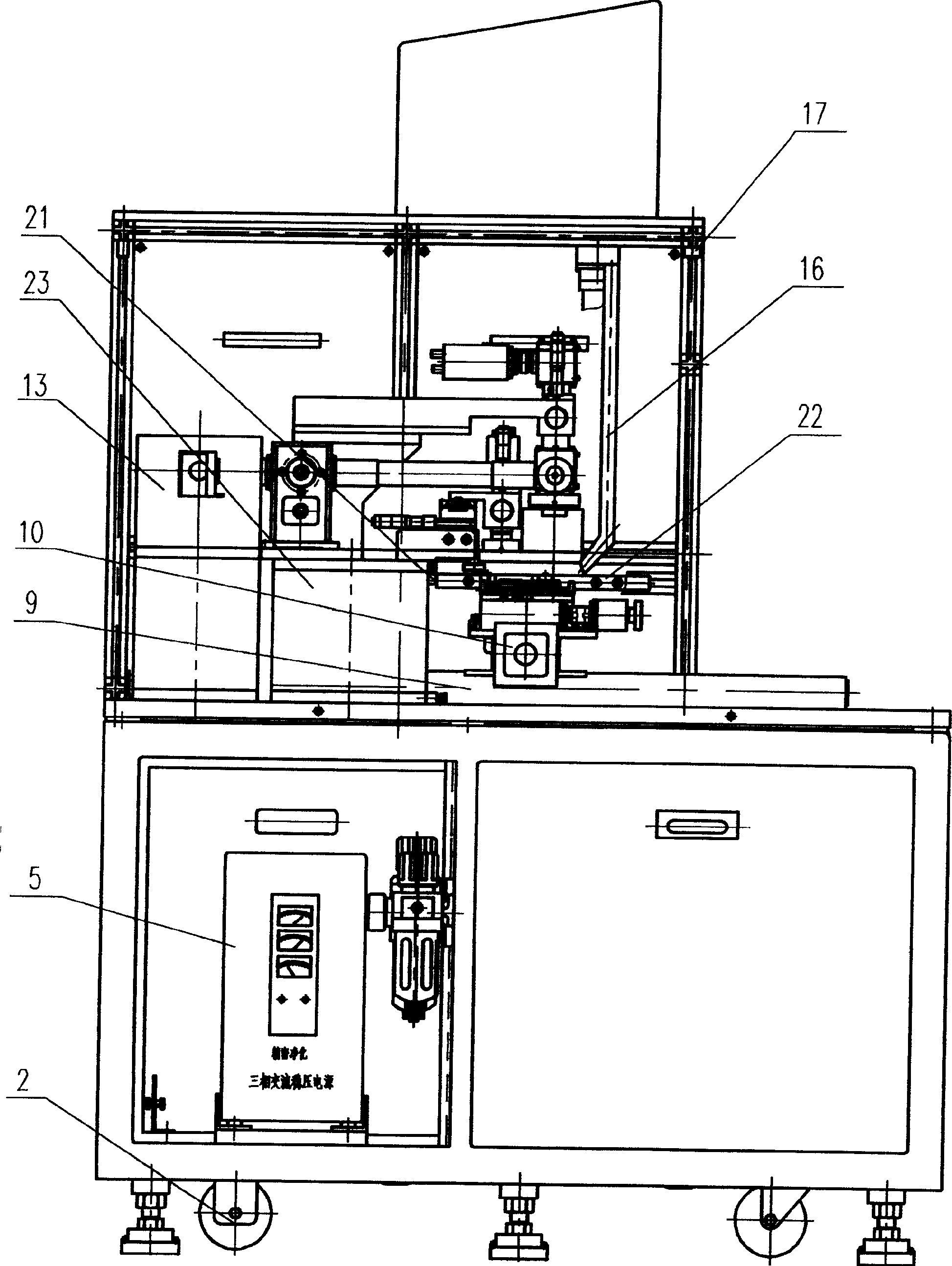

[0017] Such as Picture 1-1 , Figure 1-2 , figure 2 As shown in the preferred embodiment: it includes a leveling mechanism 1, casters 2, lower frame assembly 3, host driver 4, purification power supply 5, motion control system 6, man-machine dialogue device 7, upper frame assembly 8 , Y-axis table 9, X-axis table 10, θ-axis turntable 11, substrate carrier 12, laser cutting system 13, first alignment system 14, main control computer display screen 15, dust suction device 16, switch 17, Image monitor 18, image monitoring system 19, second alignment system 20, static electricity removal device 21, blowing device 22, frame assembly 23, workbench 24, power supply system 25, pneumatic system 26.

[0018] The first alignment system 14, the second alignment system 20, and the image monitoring system 19 all adopt a CCD camera mechanism, which is a product of Mintong Company. Y-axis table 9, X-axis table 10, and θ-axis turntable 11 use high-precision positioning platforms produced b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com