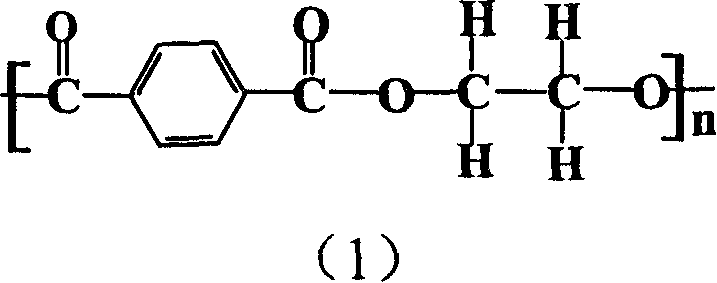

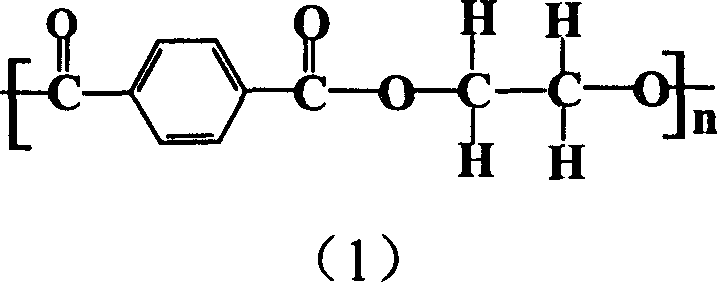

Anti-ultraviolet superfine terylene and its preparation

An ultra-fine polyester, UV-resistant technology, applied in chemical instruments and methods, single-component polyester rayon, fibrous fillers, etc., can solve the problems of poor mechanical properties and weak UV resistance, and achieve excellent mechanical properties, Remarkable function, the effect of increasing the amount of addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation of anti-ultraviolet additive through surface coupling treatment:

[0033] Add 40kg of titanium dioxide and 3kg of coupling agent into 300 liters of ethanol solution. Stirred by a strong stirrer, heated in a water bath, gradually raised to 80°C, and refluxed at a constant temperature for 60 minutes. Dry the processed powder in a blast drying oven with a temperature of 67°C. After drying, it is finely ground in a ball mill.

[0034] Preparation of UV-resistant functional masterbatch:

[0035] The anti-ultraviolet additives and adhesives treated by surface coupling are mixed evenly with bright polyester chips, and then added to a twin-screw blender for masterbatch preparation.

[0036] The amount of polyester added is 90 parts, and the anti-ultraviolet additive treated by surface coupling is 10 parts. The twin-screw speed is 60 rpm, the feeding speed is 20 rpm, and the temperature is as follows:

[0037] one unit

(feeding area)

Dyad

...

Embodiment 2

[0062] Preparation of anti-ultraviolet additive through surface coupling treatment:

[0063] Add 40kg of titanium dioxide and 10kg of coupling agent to 300 liters of ethanol solution. Stirred by a strong stirrer, heated in a water bath, gradually raised to 80°C, and refluxed at a constant temperature for 60 minutes. Dry the processed powder in a blast drying oven with a temperature of 67°C. After drying, it is finely ground in a ball mill.

[0064] Preparation of UV-resistant functional masterbatch:

[0065] The anti-ultraviolet additives and adhesives treated by surface coupling are mixed evenly with bright polyester chips, and then added to a twin-screw blender for masterbatch preparation. The amount of polyester added is 70 parts, and the anti-ultraviolet additive treated by surface coupling is 30 parts. The twin-screw speed is 250 rpm, and the feeding speed is 100 rpm.

[0066] The temperature is as follows:

[0067] one unit

(feeding area)

Dyad

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com