Leather carving process

A technique of craftsmanship and leather carving, which is applied in the direction of crafts, decorative arts, and decorative structures used to produce decorative surface effects. It can solve the problems of inaccurate patterns, blisters, and obvious wrinkles, and achieve accurate patterns, simple techniques, and Beautiful embossed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

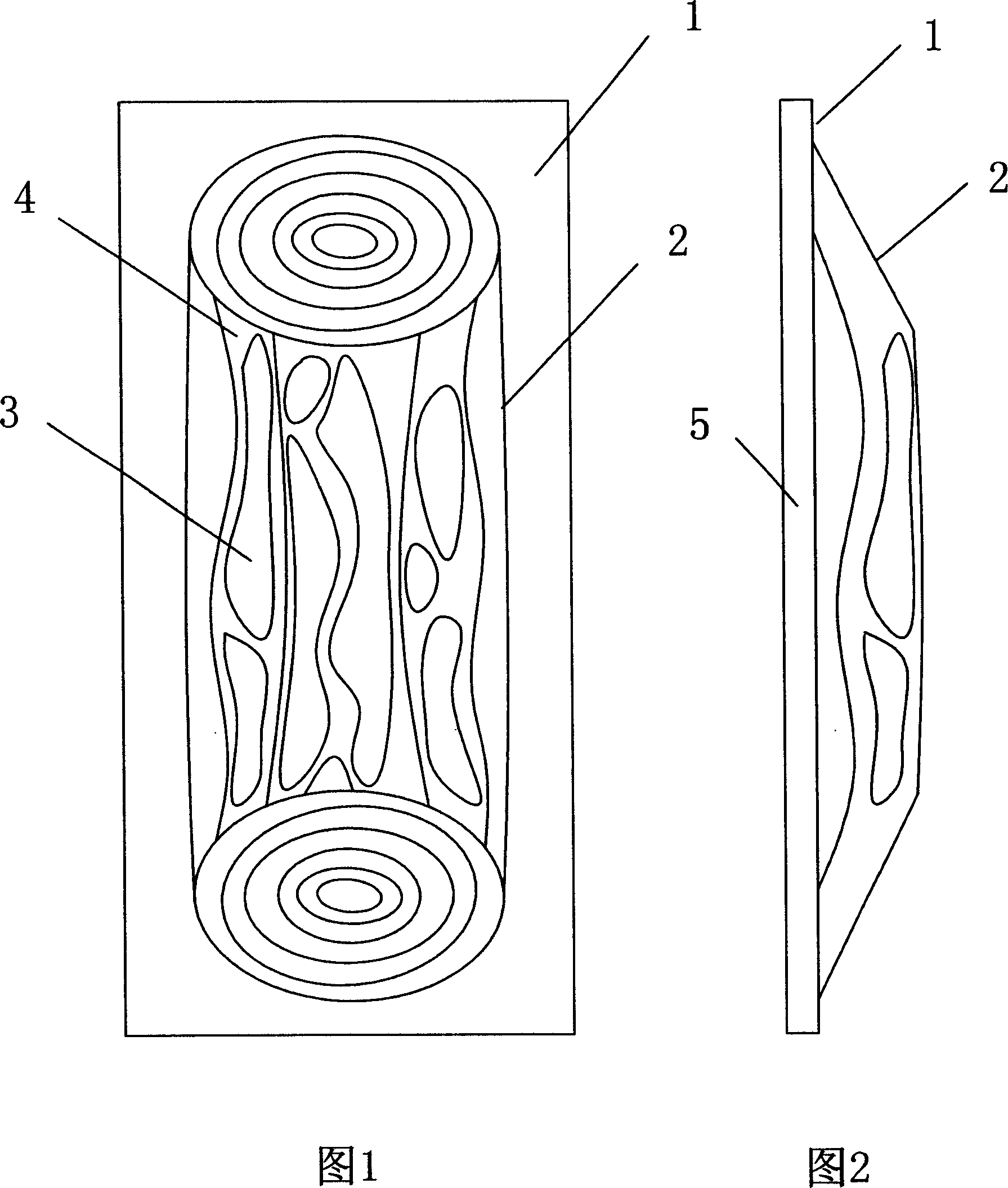

Image

Examples

Embodiment Construction

[0020] The present invention is described in further detail below.

[0021] The leather carving process includes the following steps:

[0022] Make corresponding convex and concave molds according to the selected pattern, and the convex and concave molds can be made of metal materials such as copper and iron;

[0023] The two-color PU leather with a temperature resistance of 120°C is selected. The two-color PU leather is purchased from Ningbo Comfort Company. It is a PU leather with one layer of light color and one layer of dark color. For example, two-color PU leather with dark background and light surface can be selected according to the pattern. Lay compound PVC on the back of PU leather, and punch it into semi-finished leather;

[0024] Preheat the punched semi-finished leather to 40-50°C with a heating plate;

[0025] Place the heated semi-finished leather on the punch and die;

[0026] Place the convex and concave dies in the hydraulic press for molding treatment. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com