Spiral structure type osteo-tooth implant coated with nano-apatite layer

A technology of helical structure and implant, applied in the direction of dental prosthesis, dentistry, implant, etc., can solve the problems of implant loosening and coating damage, and achieve the effect of improving occlusal force, expanding range and improving contact rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

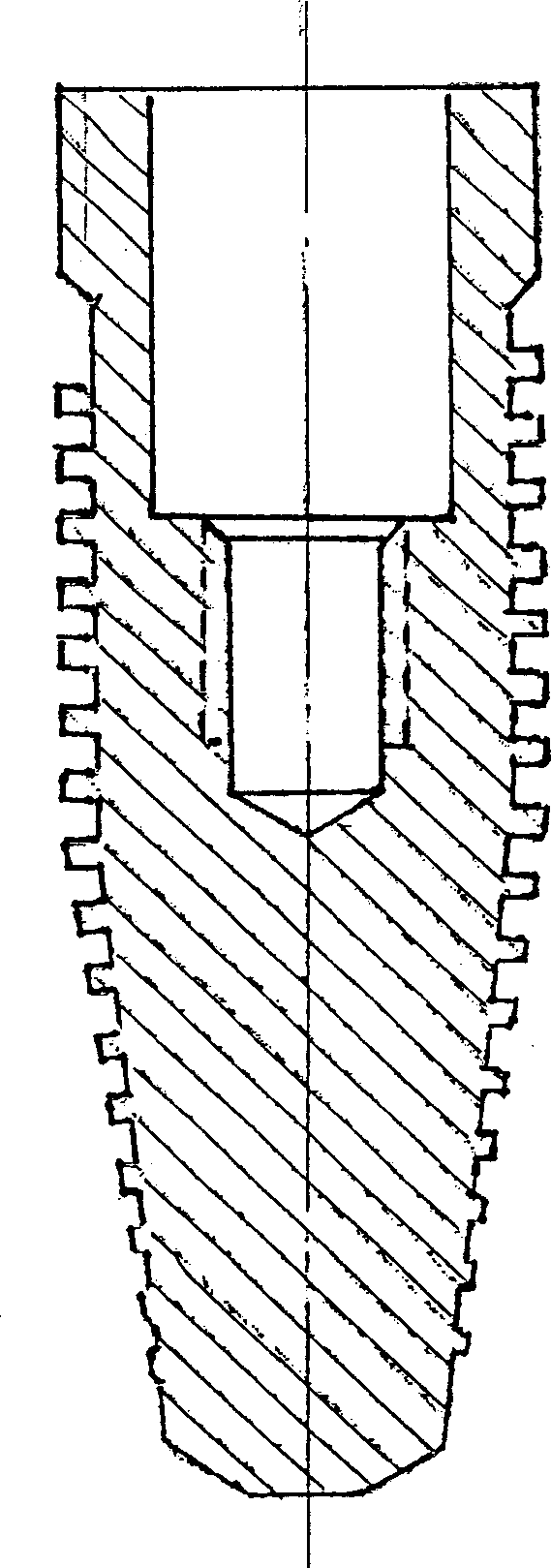

[0011] refer to figure 1 , the nano-apatite-coated helical dental bone implant of the present invention is shaped like a bullet, 1 / 2 of which is a cylinder, and the other 1 / 2 of which is a cone, and the taper of the cone is generally 1-2. 30°, the implant has an external thread, and the cross-section of the thread is rectangular; the outer surface of the implant is coated with nano-apatite, and there is a stepped hole on the axis of the cylinder for connecting with the operating abutment. The small diameter section of the stepped hole has an internal thread.

[0012] The implant implant body of the present invention can be made of pure titanium or titanium alloy.

[0013] Tests have shown that, in terms of bone mass, the lower bone section diameter of the implant implant of the present invention can be reduced by 2mm compared with the columnar implant, and the amount of bone loss is significantly reduced. In terms of bone quality, the elastic modulus of cortical bone can be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com