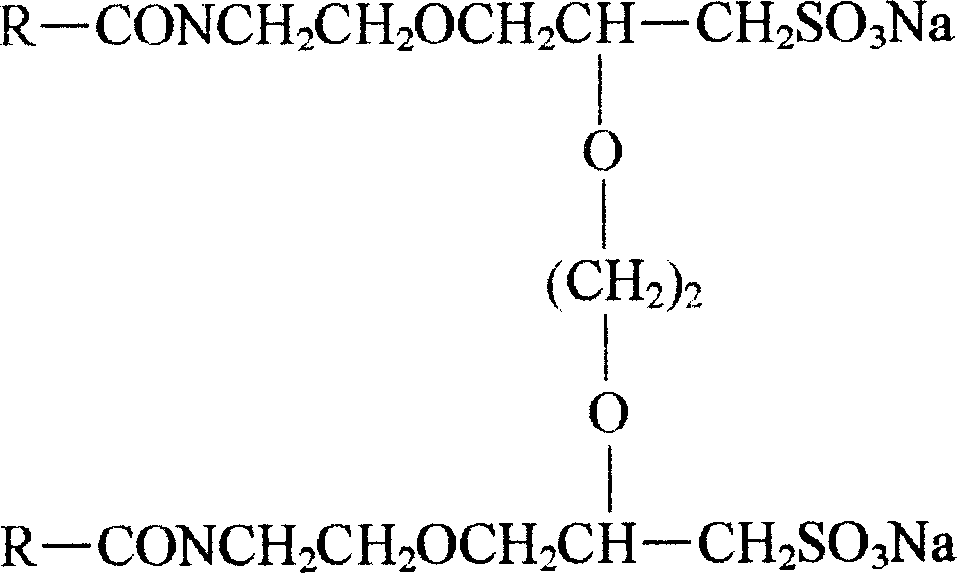

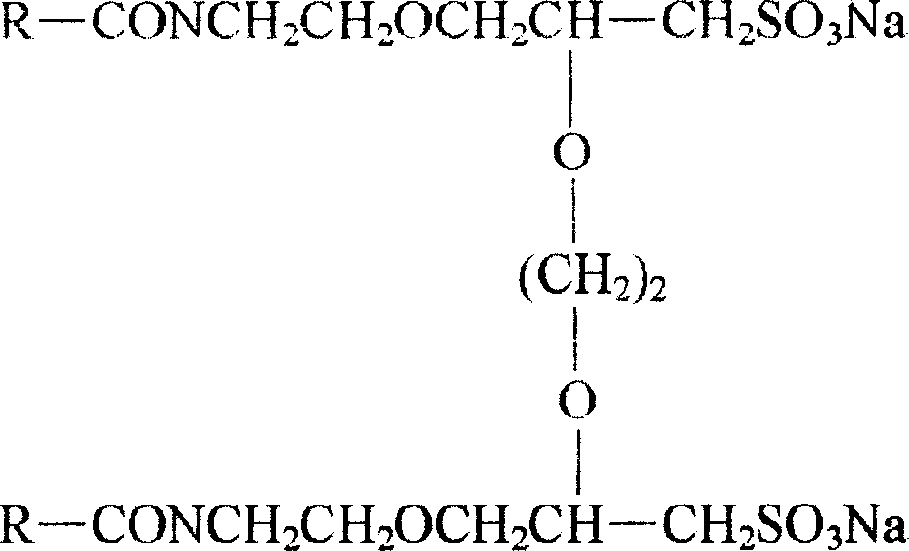

Polymerization type anion surface active agent and its prepn. method

A technology for surfactants and anions, applied in the field of polymeric anionic surfactants and its preparation, can solve the problems of non-industrial production of anionic polymeric surfactants, and achieve low critical micelle concentration, strong surface activity, and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

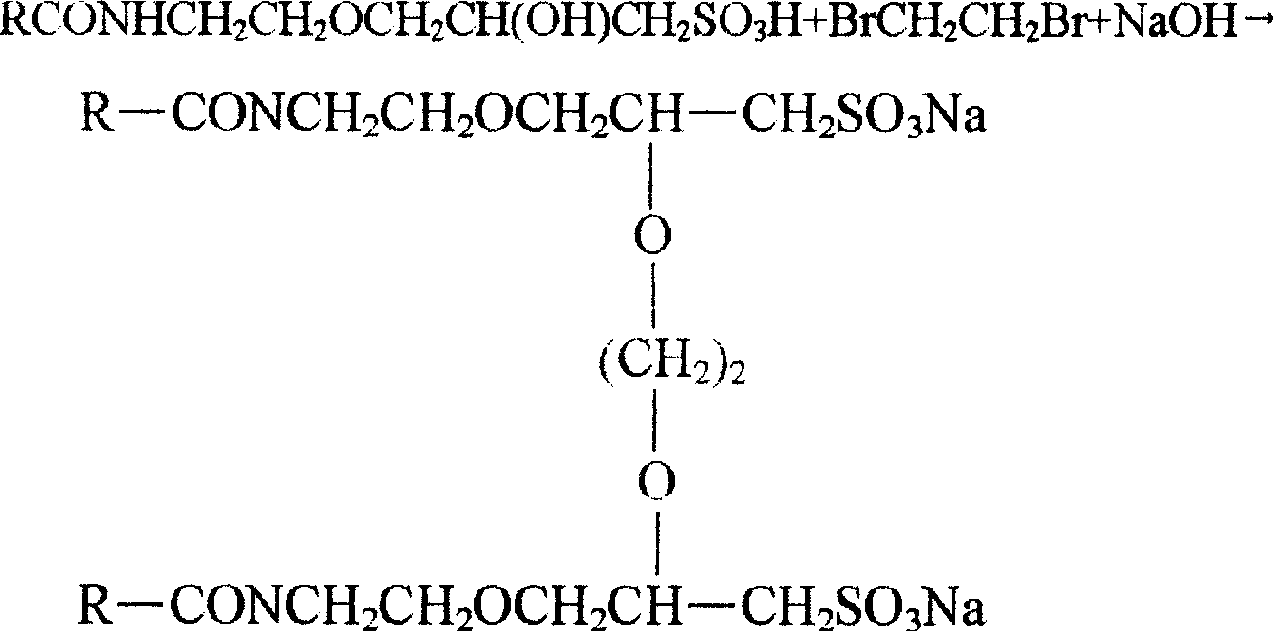

Method used

Image

Examples

Embodiment 1

[0033]

[0034] a. Amidation reaction:

[0035] Put lauric acid and monoethanolamide into the reactor, the molar ratio of the feed is: lauric acid: monoethanolamide=1:5, then add resin catalyst D005, the amount of catalyst added is 1‰ of the total reactant amount, the reaction temperature 110-120°C, react under normal pressure for 2-3 hours;

[0036] b. Add epichlorohydrin

[0037] Slowly add epichlorohydrin dropwise to the intermediate obtained in step a, the molar ratio of the feed is: intermediate obtained in step a: epichlorohydrin=1:5, and the reaction temperature is controlled at 50-60°C , to react for 2 to 3 hours under normal pressure;

[0038] c. Sulfonation reaction

[0039] The intermediate obtained in the b step is dropped into sodium bisulfite, and the mol ratio of its feed intake is: the intermediate obtained in the b step: sodium bisulfite=1: 5, and the temperature of reaction is 40~50 ℃, and reacts under normal pressure for 1 ~2 hours;

[0040] d. Polym...

Embodiment 2

[0043]

[0044] a. Amidation reaction:

[0045] Put palmitic acid and monoethanolamide into the reactor, the molar ratio of the feed is: palmitic acid: monoethanolamide=5:1, then add resin catalyst D005, the addition of catalyst is 5‰ of the total reactant amount, the reaction temperature 160-170°C, react under normal pressure for 7-8 hours;

[0046] b. Add epichlorohydrin

[0047] Slowly add epichlorohydrin dropwise to the intermediate obtained in step a, the molar ratio of the feed is: intermediate obtained in step a: epichlorohydrin=5:1, and the reaction temperature is controlled at 90-100°C , reacted under normal pressure for 7 to 8 hours;

[0048] c. Sulfonation reaction

[0049] The intermediate obtained in the b step is dropped into sodium bisulfite, and the mol ratio of its feed intake is: the intermediate obtained in the b step: sodium bisulfite=5: 1, and the temperature of reaction is 80~90 ℃, and reacts 4 under normal pressure ~5 hours;

[0050] d. Polymeriz...

Embodiment 3

[0054]

[0055] a. Amidation reaction:

[0056] Put oleic acid and monoethanolamide into the reactor, the molar ratio of the feed is: oleic acid: monoethanolamide=4:3, then add resin catalyst D005, the amount of catalyst added is 2‰ of the total reactant amount, the reaction temperature 100-120°C, react under normal pressure for 4-5 hours;

[0057] b. Add epichlorohydrin

[0058] Slowly add epichlorohydrin dropwise to the intermediate obtained in step a, the molar ratio of the feed is: intermediate obtained in step a: epichlorohydrin=4:3, and the reaction temperature is controlled at 70-80°C , reacting at normal pressure for 5-6 hours;

[0059] c. Sulfonation reaction

[0060] The intermediate that obtains in b step drops into sodium bisulfite, and the mol ratio of its feed intake is: the intermediate that b step obtains: sodium bisulfite=4: 3, and temperature of reaction is 70~80 ℃, reacts 4 under normal pressure ~5 hours;

[0061] d. Polymerization reaction

[0062]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com