Design method of a valveless self-actuated pulse combustion type kiln and kiln thereof

A technology of pulsating combustion and design method, applied in combustion equipment, lighting and heating equipment, etc., can solve the problems of low pulsating heat transfer efficiency, large peripheral size, small peripheral size, etc., and achieves convenient adjustment of pulsation frequency, small peripheral size, The effect of small aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

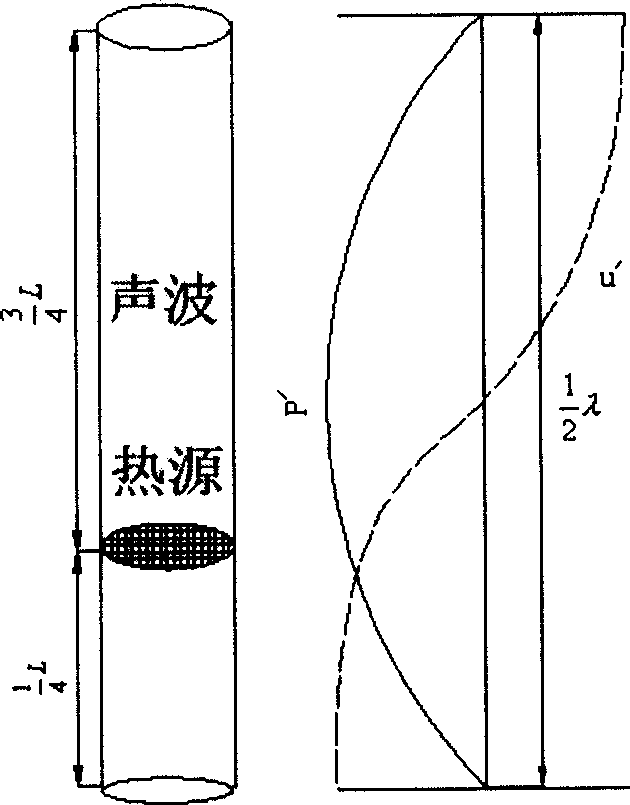

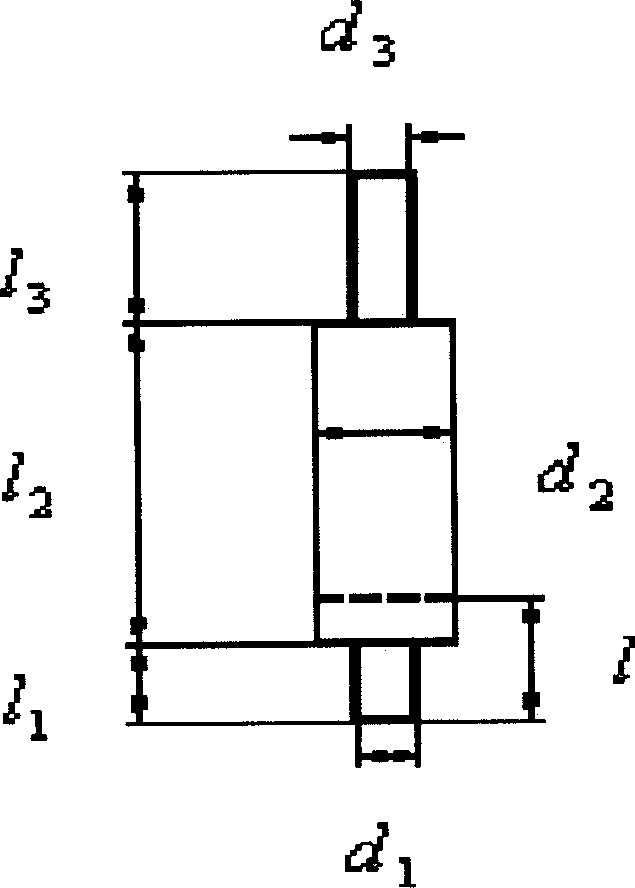

Embodiment 1

[0028] refer to figure 2 , 3 , 4. A design method for a valveless self-excited pulsating combustion furnace. In this design method, the flow distance from the fan air inlet of the burner to the fuel nozzle and the flame stabilizer is 1 / 5 to 1 of the entire gas passage flow / 3; Furnace hearth 1 adopts pipelines with multiple sections of different cross-sectional areas, and the furnace passage is branched into a plurality of smoke pipe passages 2, and the smoke pipe passage 2 is a curved passage, and the sum of the areas of each cross-section of a plurality of smoke pipe passages is 20-30% of the cross-sectional area of the furnace; the equivalent diameter d of the smoke pipe channel satisfies the following relationship (1):

[0029] d 1.84 · c o π · f - - - ...

Embodiment 2

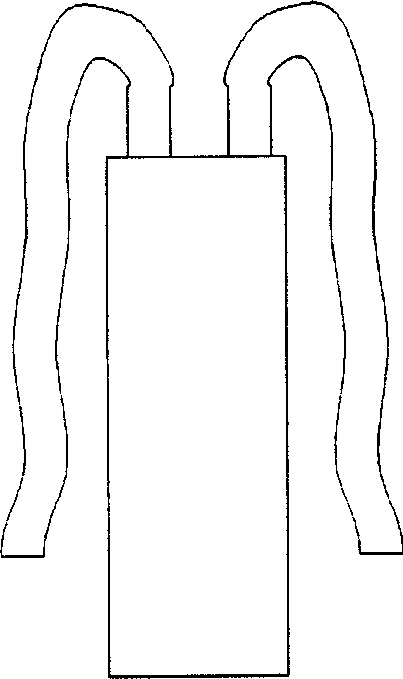

[0043] refer to figure 2 , 3 , 4, a valveless self-excited pulsating combustion type industrial furnace, including a burner, a furnace 1, a smoke pipe passage 2, a front smoke box 3, a rear smoke box 4 and a chimney, and the burner extends into the In the furnace 1, the furnace 1 is connected to the smoke pipe 2, the smoke pipe 2 is connected to the front smoke box 3, and the rear smoke box 4, and the furnace 1 is connected to a plurality of smoke pipe passages 2, and the furnace 1 is composed of Composed of pipelines with multiple sections of different cross-sectional areas, the smoke pipe passage 2 is a curved passage, and the sum of the cross-sectional areas of the multiple smoke pipe passages is 20 to 30% of the cross-sectional area of the furnace; the equivalent diameter of the smoke pipe passage is d satisfies the following relationship (1):

[0044] d 1.84 · c o ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com