Online detecting device and method for two-field leakage magnetic flux of defects on steel products surface

A detection device and detection method technology, applied in the direction of material magnetic variables, etc., can solve the problems of undetectable use, undetectable cracks, insensitivity to depth, etc., and achieve the effects of easy detection of deep cracks, improvement of product quality, and large penetration depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

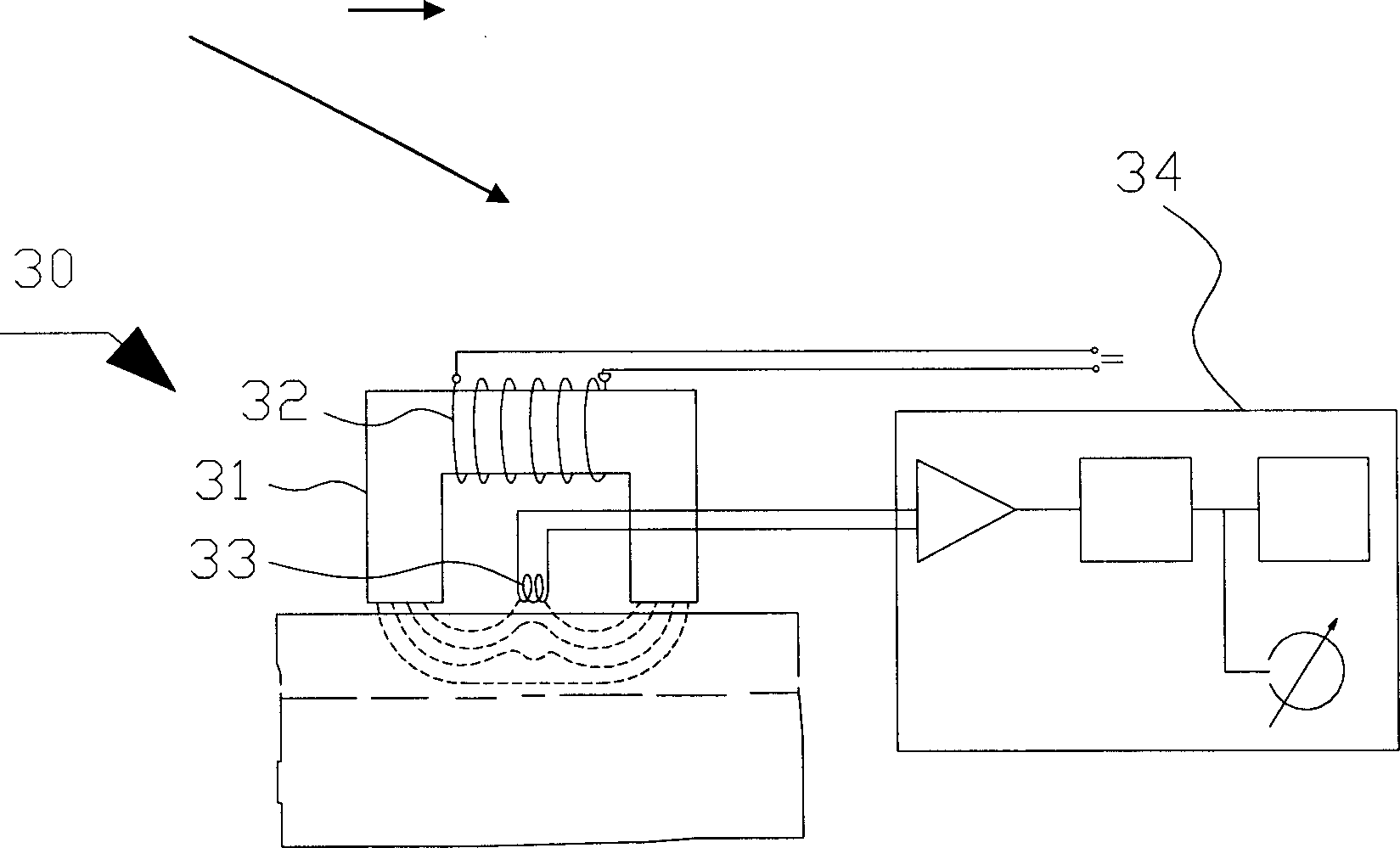

[0061] See Figure 4 , Figure 5 As shown, the on-line detection device 40 of double-field leakage magnetic flux for surface defects of steel products of the present invention includes: a stable frame 41 , a follower bracket 42 , a connecting shaft 43 , a driver 44 , a detection head 45 and a transmission rod 46 .

[0062] The stabilizing frame 41 is set as a cavity, and a connecting plate 411 is set at the top of the stabilizing frame 41; At the bottom four corners of the stabilizing bracket 41.

[0063] Follow-up support 42 is arranged in the cavity of stable frame 41, is provided with chute 421 in both sides in follow-up support 42, is provided with shaft hole in follow-up support 42 top, and four adjustment nuts 422 are arranged on follow-up support 42 bottom corners. The connecting shaft 43 passes through the shaft hole in the connecting plate 411 of the stable frame 41 and the shaft hole in the follower bracket 42 to connect the stable frame 41 with the follower brack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com