Non-circular gear series emulsion motor

A technology of emulsion and gear train, which is applied in the direction of fluid pressure actuation device, etc., can solve the problems of hydraulic motor working pressure and volumetric efficiency drop, affect the performance and life of the motor, and the emulsion does not have the lubrication function, etc., to achieve the manufacturing process Simple, good sealing, large starting torque effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

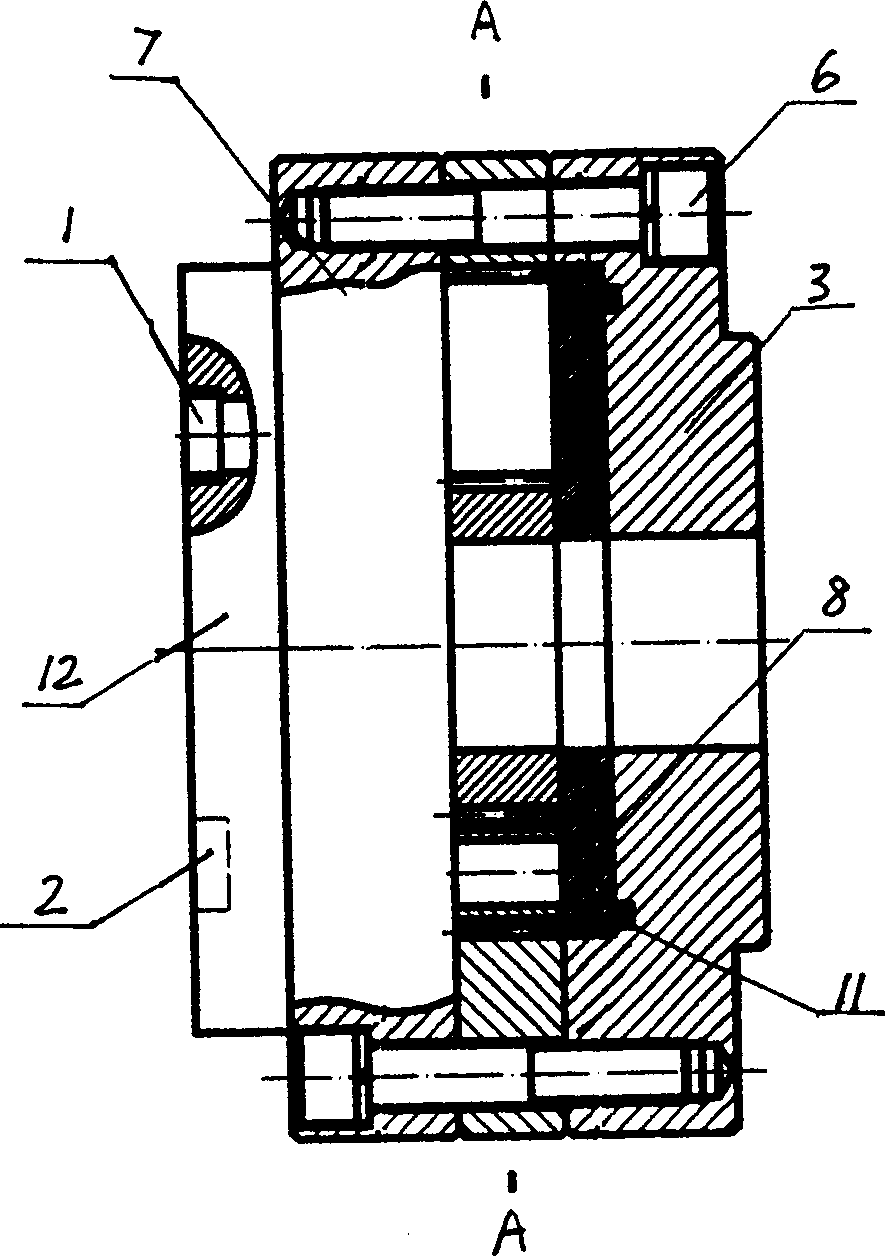

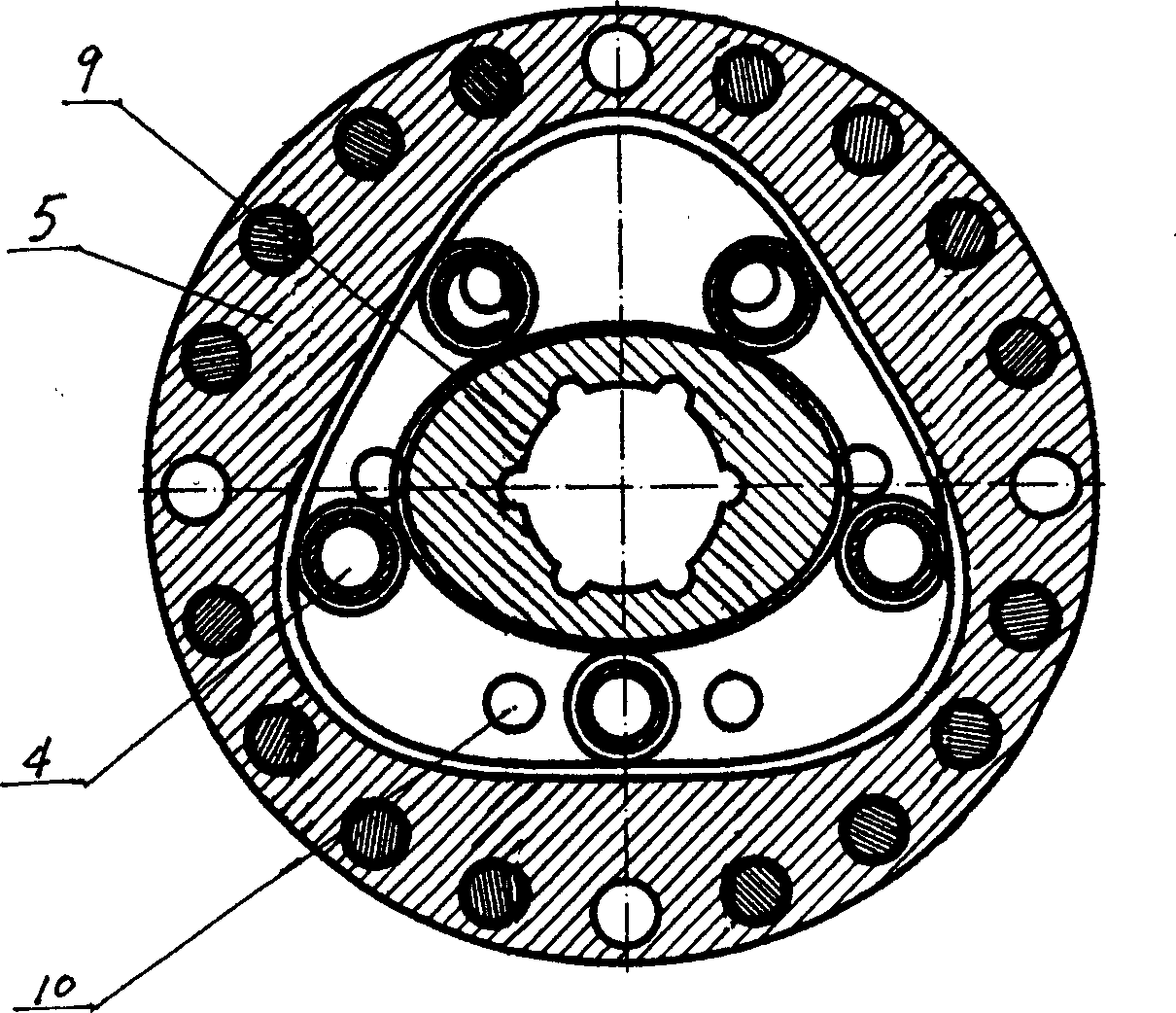

[0025] Such as figure 1 , figure 2 As shown, the emulsion hydraulic motor of the present invention includes a non-circular gear train consisting of a heart wheel 9, a peripheral wheel 5 and 5 planetary gears. The wheel train, the front side plate 3, and the rear side plate 7 form a working chamber. On the side of the front side plate facing the working chamber, a compensating plate 8 that can move slightly in the axial direction is inlaid. On the side of the compensating plate facing away from the working cavity, an elastic compensating ring 11 is installed. The compensating plate The profile of 8 is consistent with the inner curve shape of the wheel and is slightly smaller; liquid inlet 1 and liquid outlet 2 are arranged on the rear side plate 7, and the front and rear side plates 3 and 7 are fastened and connected by screws 6. The heart wheel 9 is elliptical, with two perimeters and three perimeters. The elliptical heart wheel 9 and the triangular perimeter 5 are formed a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com