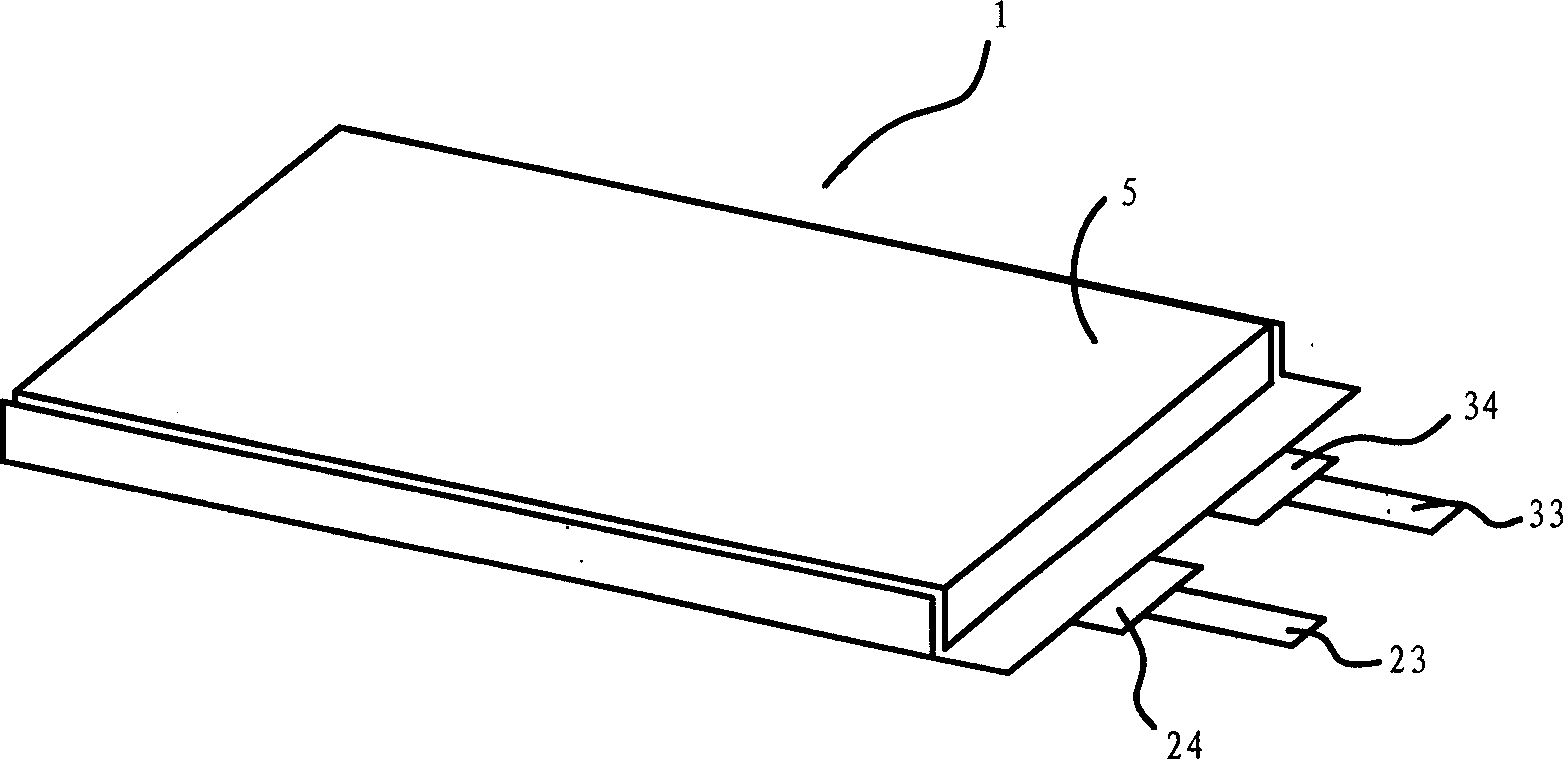

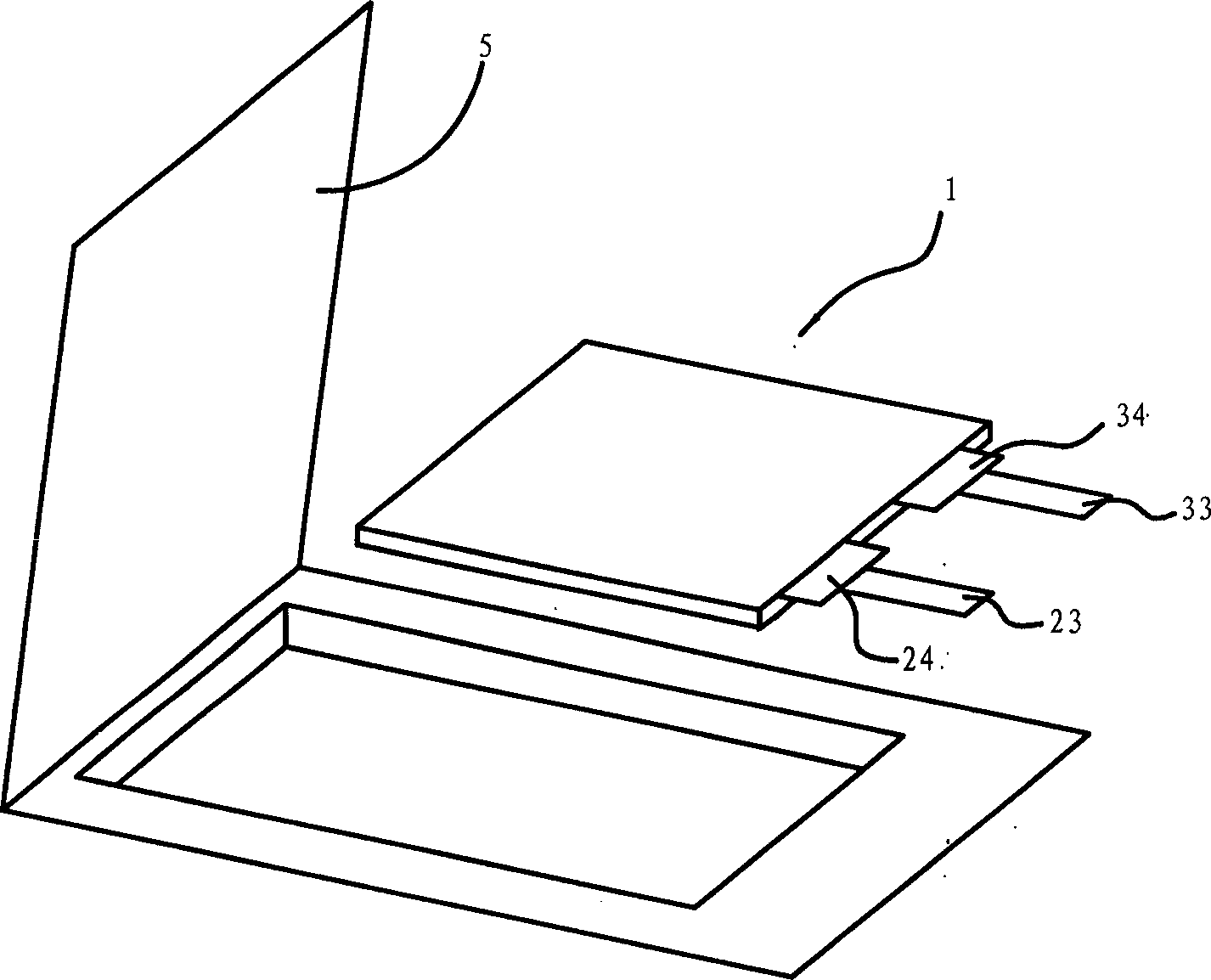

Manufacturing method of plasticized electrolytic battery

A manufacturing method and electrolyte technology, which are applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, non-aqueous electrolyte batteries, etc., can solve the problems of difficult control of the electrolyte layer and high process conditions, and achieve simple and easy-to-control processes and easy penetration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0037] The following is a specific embodiment of the present invention.

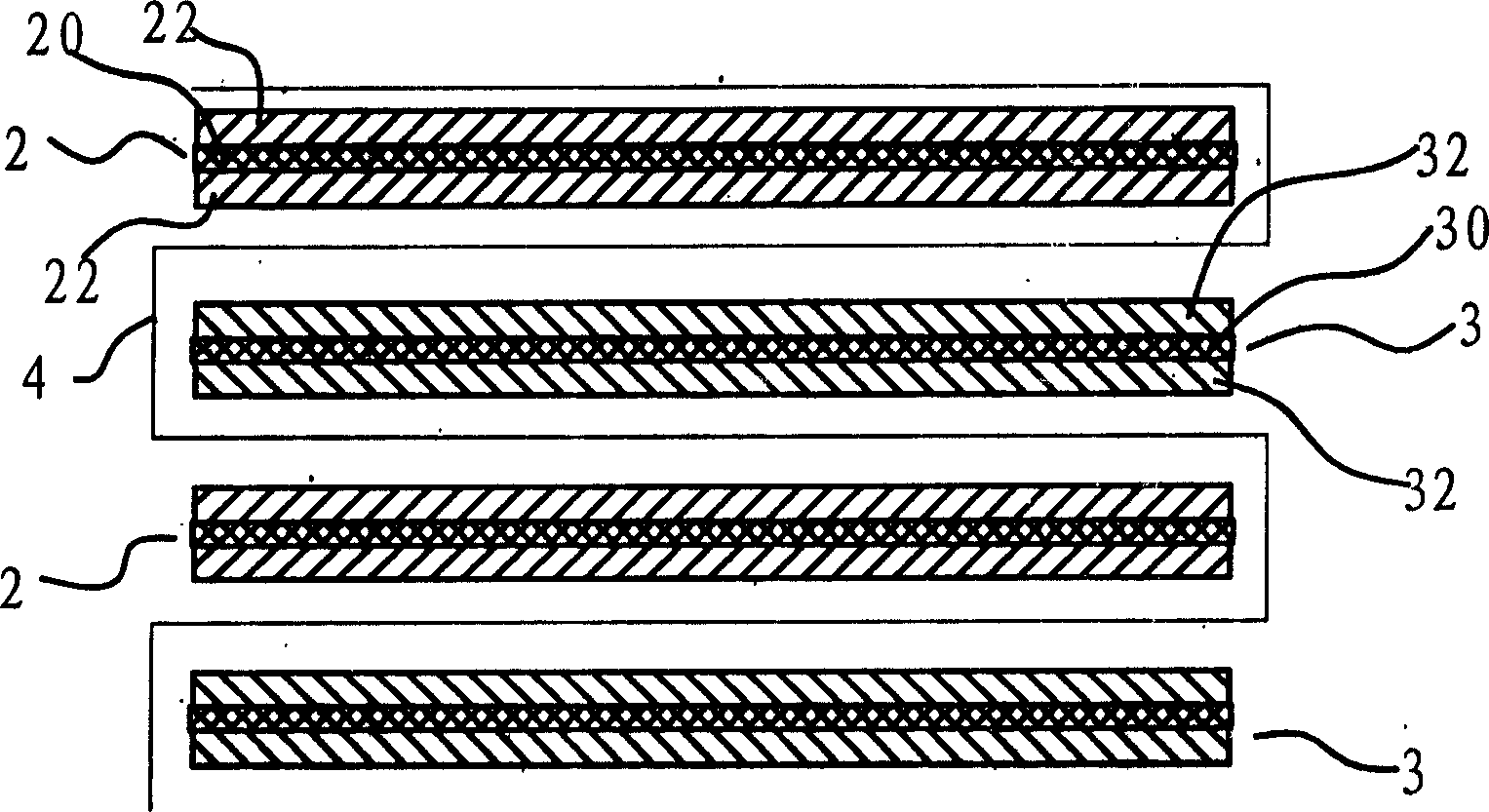

[0038] The positive electrode was prepared as follows: The slurry formulation was 91% LiCoO 2 (average particle size between 6 and 7 microns), 6% vinylidene fluoride-hexafluoropropylene copolymer, 3% carbon black, mix them into the solvent of N-methylpyrrolidone and stir to form a solid content of about 58 % of the positive electrode slurry is coated on the aluminum foil to obtain the positive electrode sheet, and after cutting, an aluminum sheet is welded on as the positive electrode lug to obtain the positive electrode.

[0039] The negative electrode was prepared in the following manner: the slurry formulation was 90% MCMB (average particle size between 15 and 18 microns), 8% vinylidene fluoride-hexafluoropropylene copolymer, 2% carbon black, and mixed them into N- A negative electrode slurry with a solid content of about 54% is formed by stirring in a solvent of methylpyrrolidone, and a negative ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com