Environmental protective heavy flint optical glass in high refractive index, and high dispersion, and producing method and equipment

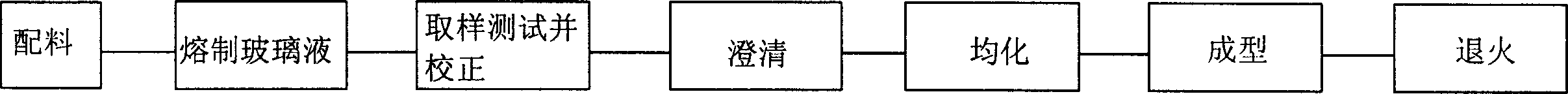

A high refractive index, optical glass technology, applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., can solve the problems affecting the optical transmission performance of glass, long production cycle, high production cost, and improve the optical transmission performance. , The effect of short production cycle and few processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The optical glass of the present invention contains 20-44% glass former SiO 2 , if SiO 2 If the content of SiO is too high, the refractive index and dispersion index of the glass cannot meet the requirements, and at the same time, the melting temperature becomes higher and it is not easy to melt; if SiO 2 If the proportion of the content is too low, the crystallization performance and chemical stability will be reduced, the preferred SiO 2 Content of 23-44%, especially preferred SiO 2 The content is 25-37%.

[0018] In addition to the glass former, a certain proportion of flux is needed to reduce the high refractive index components with high melting temperature. If the content of flux is too high, it will affect the grinding performance and chemical stability of the glass; if the content of flux is too high Low, the high refractive index component is refractory. Therefore, the flux Na in the glass 2 O+K 2 The total content of O is 7-27%, of which Na 2 O content ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com