Technique for strengthening boundary face of functional gradient material of shield duct piece by using FRP rib

A technology of functionally graded materials and shield segments, which is applied in the direction of structural elements, building components, manufacturing tools, etc., to achieve the effects of convenient construction, improved bonding strength, and saving procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

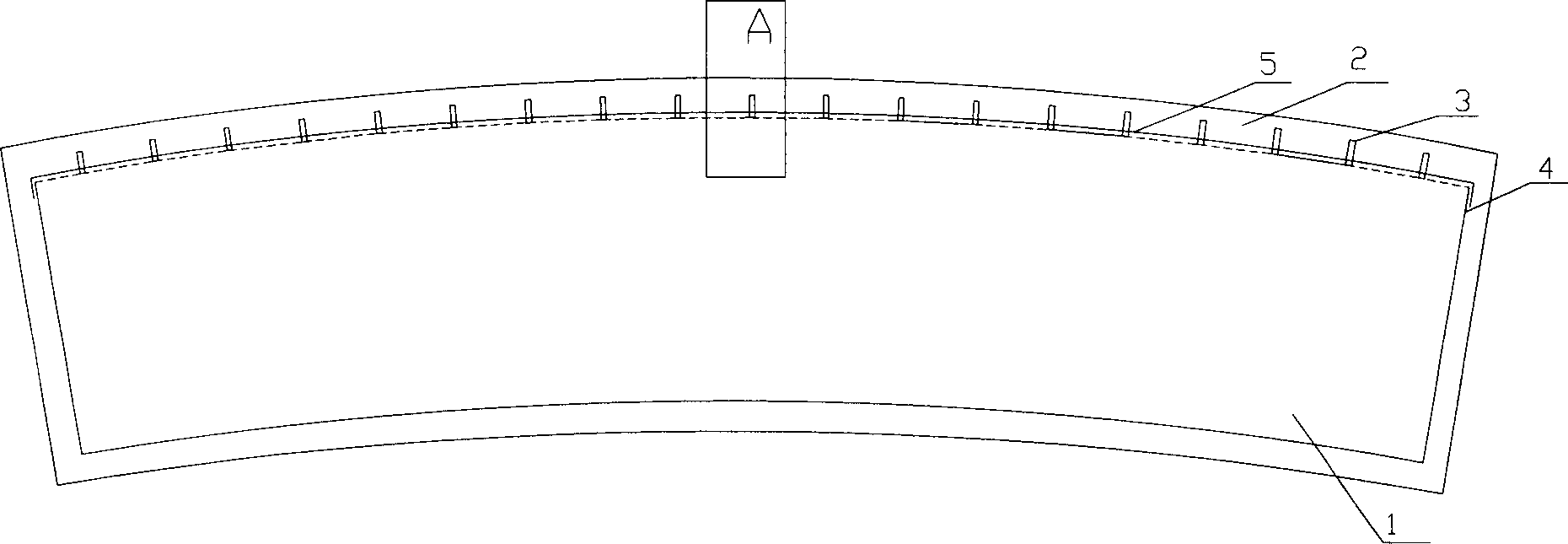

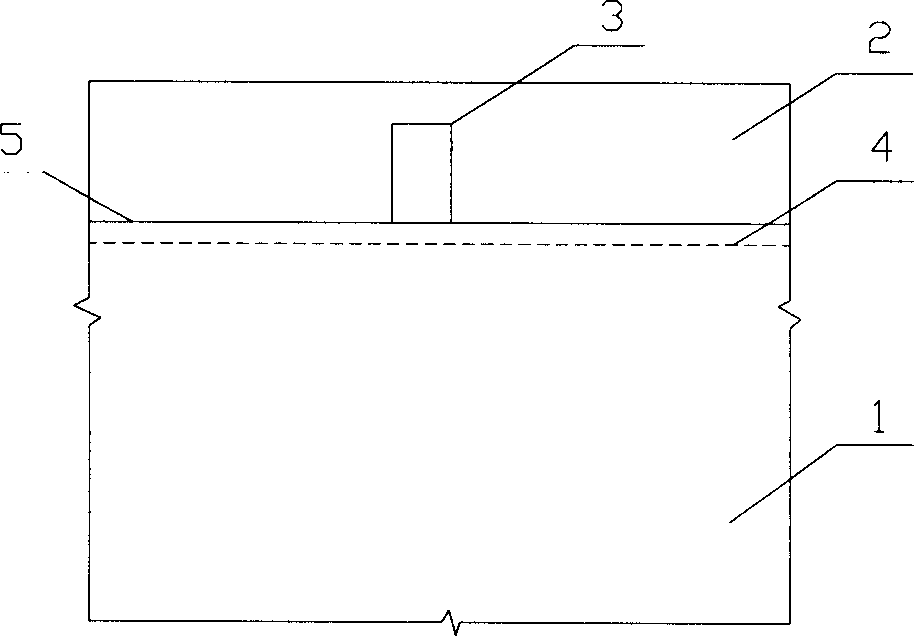

[0023] Such as figure 1 , figure 2 , image 3 As shown, a process of using FRP bars to strengthen the functionally graded material interface of the shield segment. The interface between the reinforced concrete structure layer 1 and the high impermeability protection layer 2 of the shield tunnel concrete segment is a functionally graded material interface. Including the following steps:

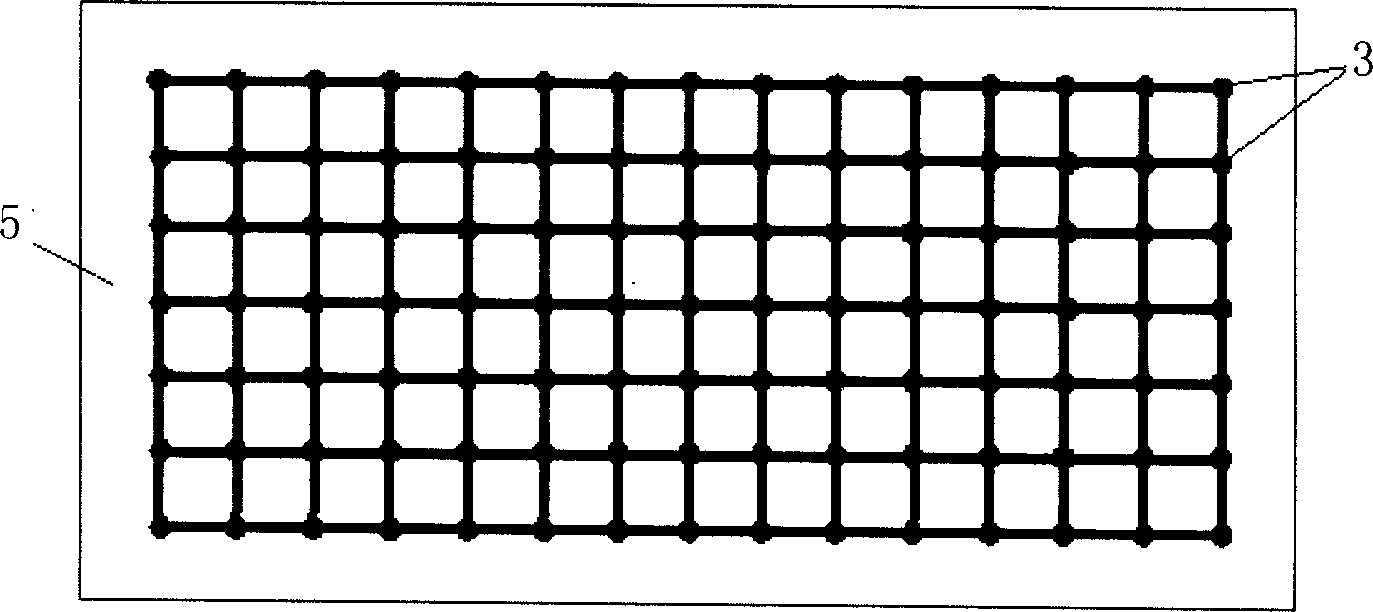

[0024] 1) Establish the FRP tendon anchoring and strengthening transition zone: FRP tendons 3 and flexible FRP mesh cloth 5 are combined to form the FRP tendon interface anchoring reinforcement material, and the preparation process of FRP tendons 3 and flexible FRP mesh cloth 5 is prefabricated in the factory and mass-produced , can be used directly in the preparation process of the shield segment, so as not to affect the construction progress; the outer surface of the FRP reinforcement is a threaded structure, with a diameter of 20mm and a length of 30mm. The spacing between adjacent FRP ...

Embodiment 3

[0043] Such as figure 1 , figure 2 , image 3 Shown, a kind of technology that utilizes FRP rib to strengthen the functionally graded material interface of shield segment, it comprises the following steps:

[0044] 1) Establish the anchoring and strengthening transition zone of FRP tendons: the outer surface of FRP tendons is a threaded structure with a diameter of 30 mm and a length of 40 mm. The distribution of FRP tendons on the grid cloth is distributed in a lattice, and the distance between two adjacent FRP tendons is: 90mm.

[0045] Before the concrete is poured, the flexible FRP grid cloth 5 is laid and pasted on the steel cage surface 4 in the reinforced concrete segment steel mold, and the FRP bars 3 are distributed on the flexible FRP mesh cloth 5 in a lattice shape to form the FRP bar anchoring strengthening transition area, in which FRP tendons (3) and FRP mesh cloth (5) are bonded to form an integral structure, which is completed through factory prefabrication...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com