Fuel blends for hydrogen generators

A technology of mixtures and borohydride compounds, which can be used in fuel, hydrogen production, liquid carbon-containing fuels, etc., and can solve the problem of hydrogen storage capacity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] General method for hydrogen generation from fuel mixtures

[0036] Hydrogen generation experiments are generally described using sodium borohydride, decaborane, sodium hydroxide, and water in a fuel mixture as a sample system. Fuel mixtures were prepared under open air conditions. Water and stabilizing sodium hydroxide are initially mixed, to which decaborane is added, followed by the appropriate amount of sodium borohydride to achieve the desired ratio.

[0037] To catalyze the exhaust fuel mixture, a Parr reactor placed on a hot plate was used. The reactor is incorporated with two thermocouples that operate continuously during operation, one of which measures the temperature of the fuel solution and the other measures the temperature of the headspace near the top of the reactor. When the second thermocouple registered a threshold temperature of 95° C., the second thermocouple control started cycling through the cooling loop of the reactor. But the reality is that e...

Embodiment 2

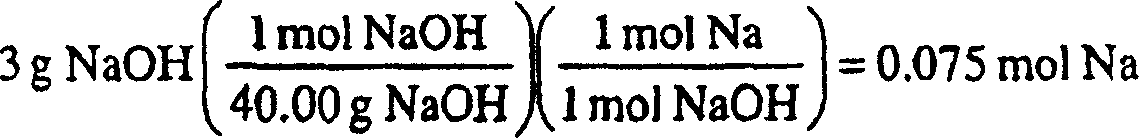

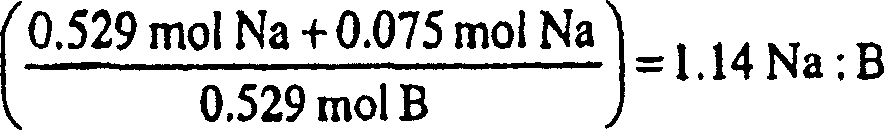

[0040] 7.0% by weight hydrogen, + IC / B ratio = 0.8

[0041] Mix the following substances according to the method in Example 1 to obtain 100g capable of releasing 7.0% by weight H 2 A fuel mixture with a ratio of sodium to boron of 0.8: sodium borohydride 27.16 g; sodium hydroxide 3 g; decaborane (14) 3.34 g and water 66.5 g. According to reaction formula (1), every mole of sodium borohydride produces four moles of hydrogen.

[0042] (1)

[0043] According to reaction formula (2), every mole of decaborane (14) produces 22 moles of hydrogen.

[0044] (2)

[0045] generate H by calculation 2 and divide by the initial weight of the mixture to determine the hydrogen storage capacity of the mixture.

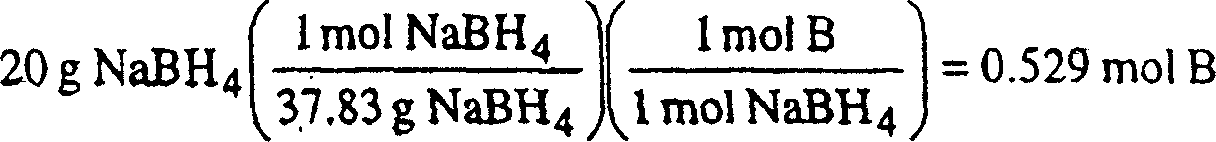

[0046] from NaBH 4 middle:

[0047] 27.16 g NaBH 4 ( 1 mol NaBH ...

Embodiment 3

[0063] 6.8% by weight hydrogen, + IC / B ratio = 0.25

[0064] Mix the following materials according to the method in Example 1 to obtain 100g capable of releasing 6.8% by weight H 2 Fuel mixture with a sodium to boron ratio of 0.25: sodium triborohydride 13.74 g; sodium dodecahydrododecaborate 13.74 g and water 76.09 g. According to reaction formula (3), every mole of sodium dodecahydrododecaborate produces 25 moles of hydrogen gas.

[0065] (3)

[0066] According to reaction formula (4), every mole of sodium triborohydride produces nine moles of hydrogen.

[0067] (4)

[0068] generate H by computing 2 and divide by the initial weight of the mixture to determine the hydrogen storage capacity of the mixture.

[0069] From Na 2 B 12 h 12 middle:

[0070] 10.17 g Na 2 B 12 H 12 ( ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com