Novel waste incineration fly ash pulping, washing and carbon neutralization coupling system and method

A waste incineration fly ash and coupling system technology, which is applied in the field of new waste incineration fly ash pulping water washing and carbon neutral coupling system, can solve the problems of easy explosion, small fly ash particle size, dust pollution, etc., and improve utilization The effect of improving efficiency, improving solid-liquid separation efficiency and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

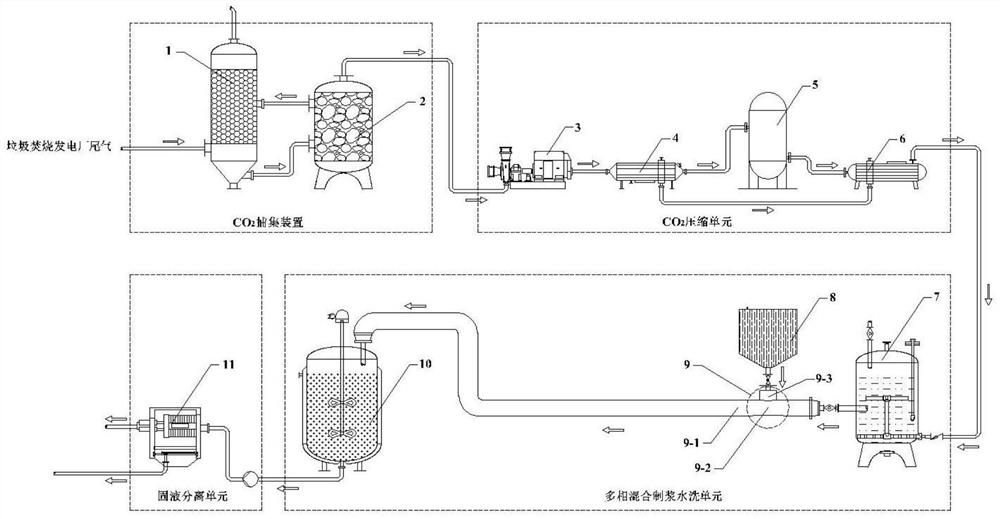

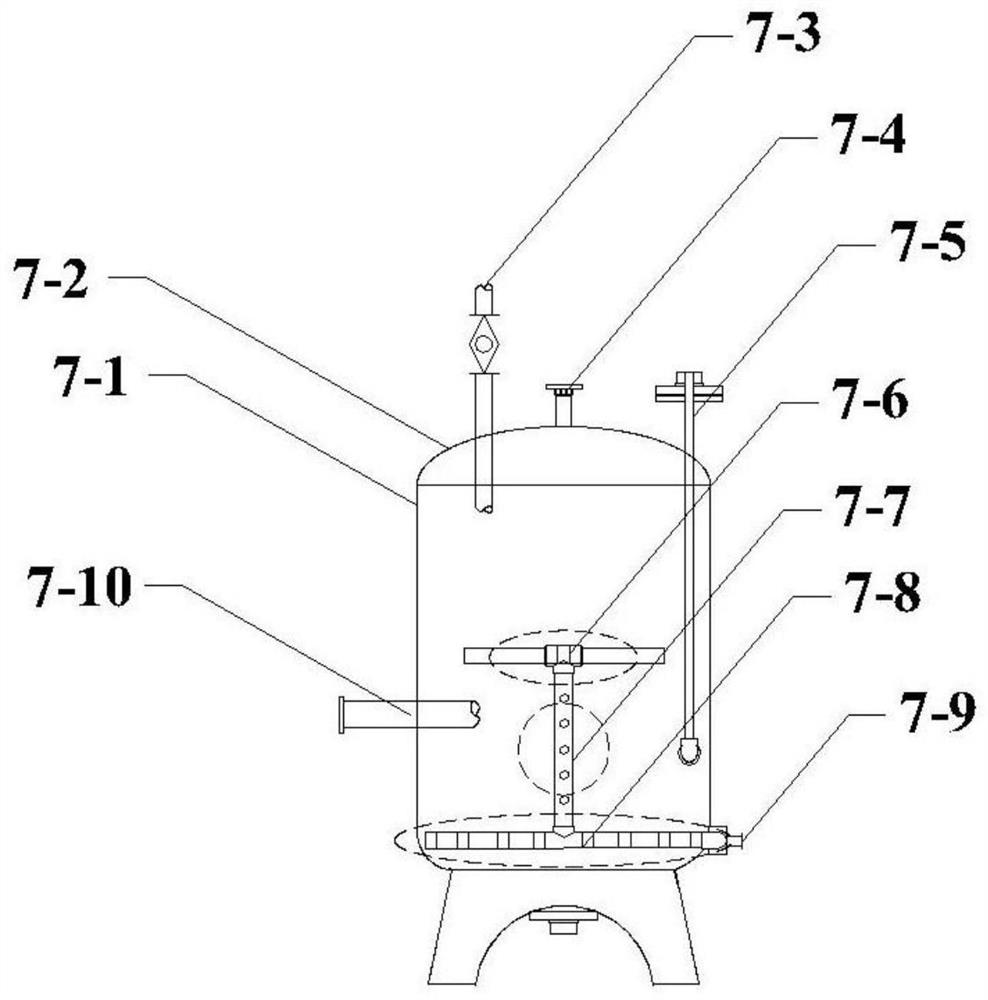

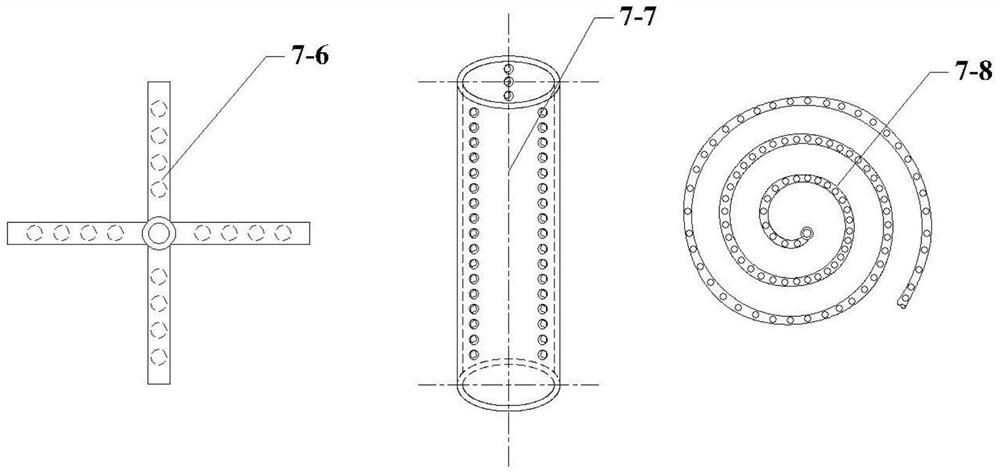

[0035] Such as figure 1 As shown, a new type of waste incineration fly ash pulping water washing and carbon neutral coupling system, including CO 2 capture device, CO 2 Compression unit, multi-phase mixing pulping water washing unit and solid-liquid separation unit. CO 2 The trapping device includes an adsorption furnace 1 and a high-temperature roasting furnace 2 .

[0036] The adsorption furnace 1 is filled with an adsorbent. The adsorbent adopts calcium-based zeolite molecular sieve. The air inlet of the adsorption furnace 1 is connected with the tail gas pipeline. The tail gas of the waste incineration power plant enters the adsorption furnace 1 through the tail gas pipeline. The adsorption furnace 1 is connected with the high-temperature roasting furnace 2 through a circulation pipeline. The top of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com