Leaf fertilizer special for strawberries and production method of leaf fertilizer

A production method and foliar fertilizer technology, applied in the application, nitrogen fertilizer, potassium fertilizer and other directions, can solve the problems of fruit yield reduction, sufficient elements required for strawberries, etc., to achieve comprehensive nutrients, reduce water transpiration loss, and improve the ability of the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

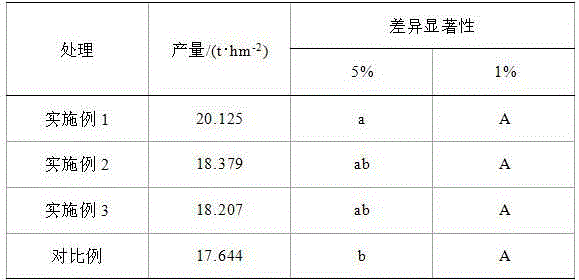

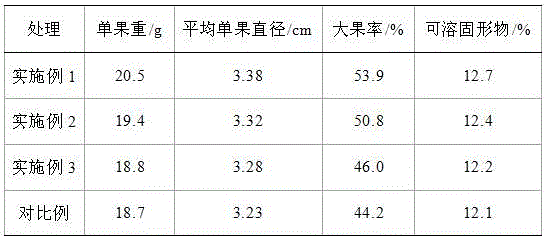

Examples

Embodiment 1

[0037] 407 kg of raw material urea, 300 kg of potassium chloride, 114 kg of monoammonium phosphate, 5 kg of ferrous sulfate, 4 kg of EDTA-Fe, 8 kg of magnesium nitrate, 7 kg of zinc sulfate, 8 kg of borax, 10 kg of ammonium molybdate, 137 kg of humic acid was weighed and added to 1# mixing tank and 2# mixing tank respectively, dissolved with 1000 L of soft water, heated with jacket steam in the mixing tank, and the temperature was maintained at 40-60°C, and the fully dissolved materials were mixed with The pump is sent to the buffer tank, the buffer tank is jacketed and kept cold, and the soft water (15-20 ℃) is used to cool it to room temperature, and then it is transported to the high level tank by the buffer feeding pump, and there is a pipeline on the pipeline entering the high level tank Filter, the material entering the high-level tank is filtered by the pipeline filter, the material in the high-level tank is metered into the filling machine, and then packed in the fill...

Embodiment 2

[0040] 363 kg of raw material urea, 240 kg of potassium chloride, 114 kg of monoammonium phosphate, 6 kg of ferrous sulfate, 4 kg of EDTA-Fe, 6 kg of magnesium nitrate, 7 kg of zinc sulfate, 8 kg of borax, 9 kg of ammonium molybdate, 243 kg of humic acid was weighed and added to 1# mixing tank and 2# mixing tank respectively, dissolved with 1000 L soft water, heated with jacket steam in the mixing tank, and the temperature was kept at 40-60°C, and the fully dissolved materials were mixed with The pump is sent to the buffer tank, the buffer tank is jacketed and kept cold, and the soft water (15-20 ℃) is used to cool it to room temperature, and then it is transported to the high level tank by the buffer feeding pump, and there is a pipeline on the pipeline entering the high level tank Filter, the material entering the high-level tank is filtered by the pipeline filter, the material in the high-level tank is metered into the filling machine, and then packed in the filling machin...

Embodiment 3

[0043] 363 kg of raw material urea, 300 kg of potassium chloride, 114 kg of monoammonium phosphate, 6 kg of ferrous sulfate, 4 kg of EDTA-Fe, 6 kg of magnesium nitrate, 6 kg of zinc sulfate, 10 kg of borax, 9 kg of ammonium molybdate, humic 182 kg of acid was weighed and added to 1# mixing tank and 2# mixing tank respectively, dissolved with 1000 L of soft water, heated with jacket steam in the mixing tank, and the temperature was maintained at 40-60 ° C, and the fully dissolved materials were mixed with a mixing pump It is transported to the buffer tank, the buffer tank is jacketed and kept cold, cooled to normal temperature by the soft water (15-20 ℃) delivered, and then transported to the high level tank by the buffer feed pump, and the pipeline entering the high level tank is installed with pipeline filtration The material entering the high-level tank is filtered by the pipeline filter, and the material in the high-level tank is metered into the filling machine, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com