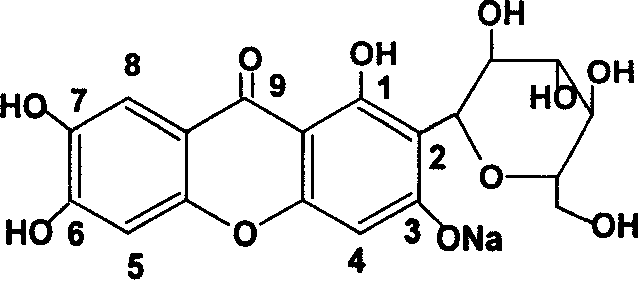

Preparation method and application of water-soluble mangiferin monosodium salt

A technology of monosodium glycoside and mangiferin, which is applied in the field of chemical pharmacy, can solve the problems of poor water solubility, difficult medicinal liquid, influence on curative effect and its application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

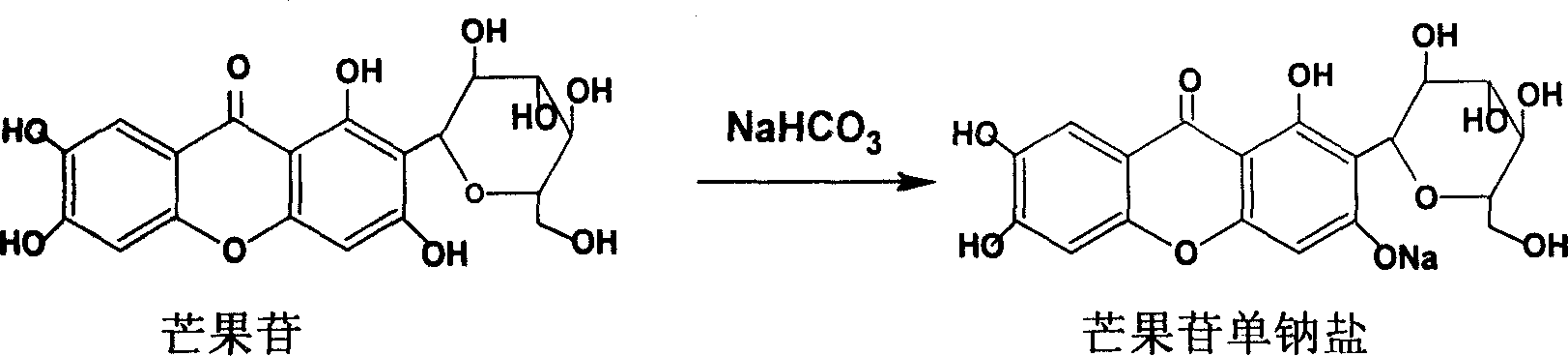

Method used

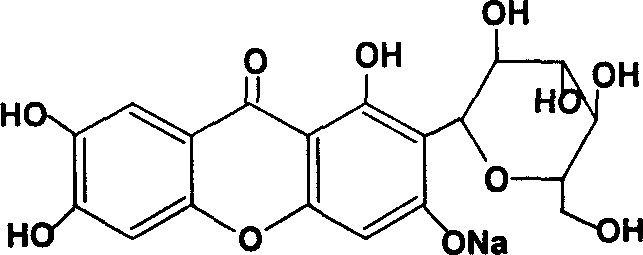

Image

Examples

Embodiment 1

[0008] Place the 50ml three-necked bottle equipped with a stirrer and dropping funnel in a constant temperature water bath that has been heated to 60°C, add 5ml acetone and 2ml water in the three-necked bottle, add 0.422g mangiferin (0.001mol), and stir After the mangiferin and the solvent are fully mixed, 1.5% sodium bicarbonate solution (5.6ml, 0.001mol) is added dropwise while stirring, and the dripping is completed within 15 minutes. Continue to stir, and react at a constant temperature for 5 to 10 minutes, and the solution becomes clear. Quickly add 30ml of acetone, stir for 5-10min, cool to room temperature, filter, wash with acetone, and dry in a vacuum oven at 50-60°C for 2-3h to obtain 0.412g of mangiferin monosodium salt with a weight yield of 92.8%. The product obtained was yellow powder in appearance.

Embodiment 2

[0010] Place the 50ml three-necked bottle equipped with a stirrer and dropping funnel in a constant temperature water bath that has been heated to 60°C, add 8ml acetone and 1ml water in the three-necked bottle, add 0.422g mangiferin (0.001mol), and stir After the mangiferin and the solvent are fully mixed, 1.5% sodium bicarbonate solution (5.6ml, 0.001mol) is added dropwise while stirring, and the dripping is completed within 15 minutes. Continue to stir, and react at a constant temperature for 5 to 10 minutes, and the solution becomes clear. Quickly add 20ml of dichloromethane and acetone (volume ratio 1:1) mixed solution, stir for 10-15min, filter, wash with acetone, and dry in a vacuum oven at 50-60°C for 4-5h to obtain 0.364g of monosodium mangiferin, weight The yield was 81.9%. The product obtained was yellow powder in appearance.

Embodiment 3

[0012] Place the 50ml three-necked bottle equipped with a stirrer and dropping funnel in a constant temperature water bath that has been heated to 60°C, add 3ml acetone and 2ml water in the three-necked bottle, add 0.422g mangiferin (0.001mol), and stir After the mangiferin and the solvent are fully mixed, 1.5% sodium bicarbonate solution (5.6ml, 0.001mol) is added dropwise while stirring, and the dripping is completed within 15 minutes. Continue to stir, and react at a constant temperature for 5 to 10 minutes, and the solution becomes clear. Quickly add 40ml of dichloromethane and acetone (volume ratio 1:1) mixed solution, stir for 10-15min, filter, wash with acetone, and dry in a vacuum oven at 50-60°C for 4-5h to obtain 0.375g of monosodium mangiferin, weight The yield was 84.5%. The product obtained was yellow powder in appearance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com