Preparation technique of solvent red 179

A production process, solvent red technology, applied in the production process field of solvent red 179, can solve the problems of increased production cost, poor product quality, difficult recycling, etc., and achieve the effects of cost reduction, less emissions, and production cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

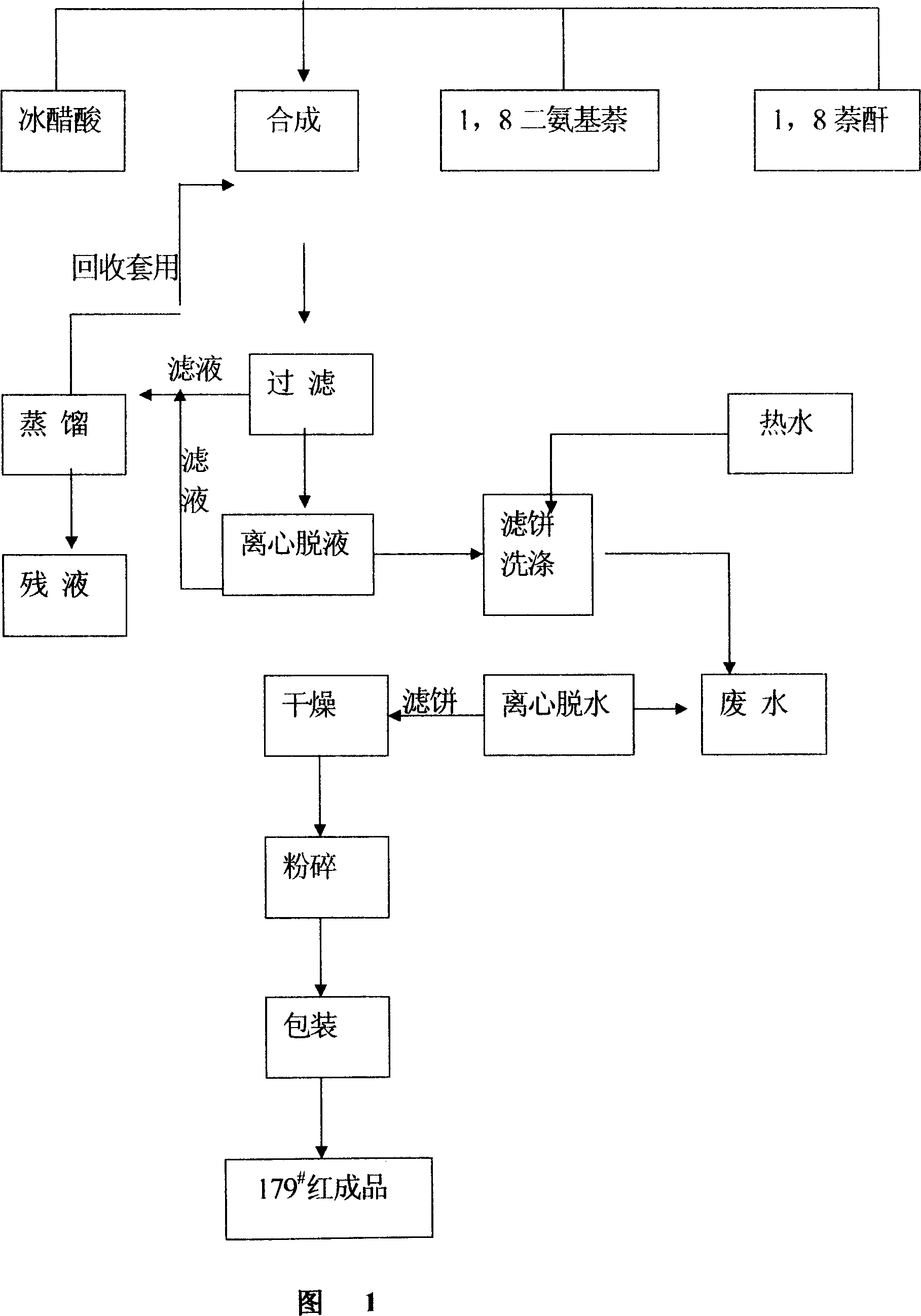

[0021] Below in conjunction with accompanying drawing, the present invention will be further described:

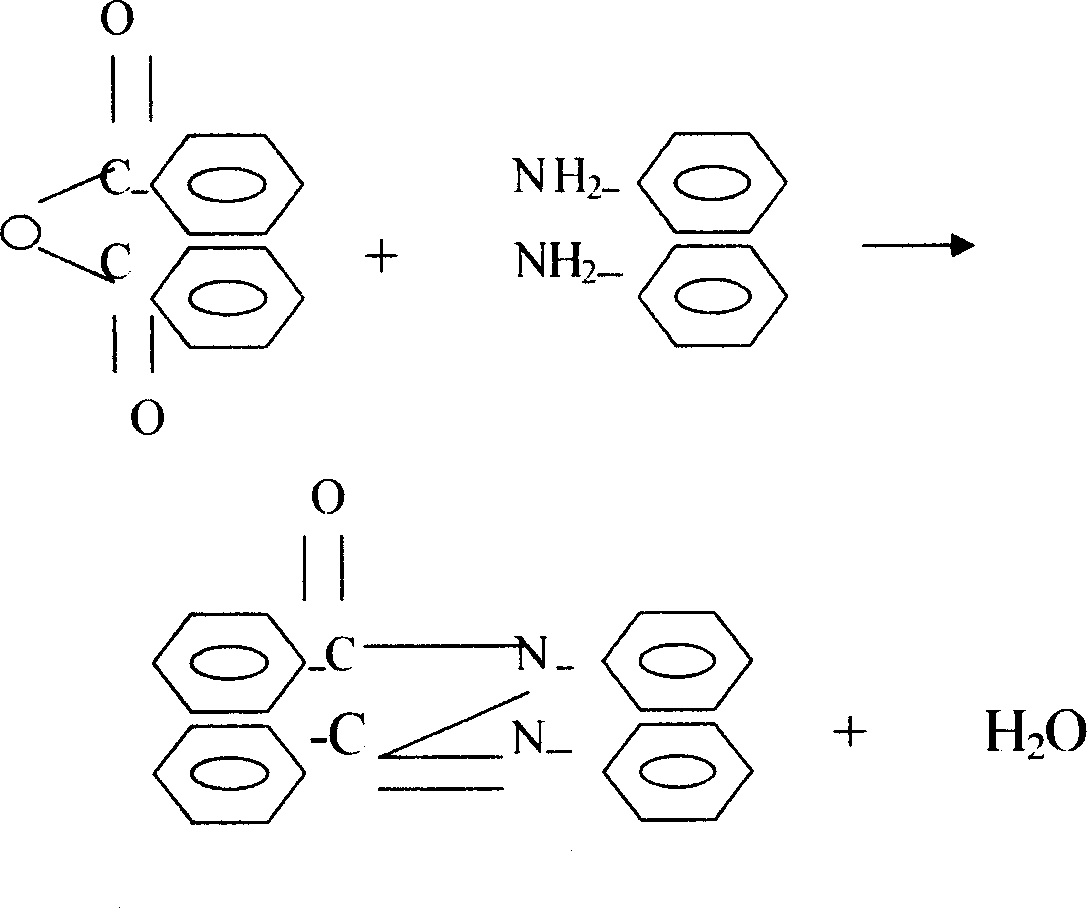

[0022] 1. Synthesis: pump glacial acetic acid whose solvent accounts for 10-15 times the total weight of raw materials in the reaction kettle, start stirring, put in raw materials 1,8 naphthalene anhydride raw materials, and then add raw materials 1,8 diaminonaphthalene raw materials, 1,8 naphthalene The molar ratio of anhydride and 1,8 diaminonaphthalene dosage is put into by 1: 1.01, then add the auxiliary agent Kao A-60 (chemical name: ammonium molybdate) whose dosage is 1-1.5‰ of the total weight of raw materials, and put in the cap after casting. Open the water inlet and outlet valves of the condenser, heat up the steam entering the jacket, and raise the temperature to 110-116°C in about 1 hour, keep it in the reflux state for 10-15 hours, after the heat preservation is over, cool down to 35-45°C, and keep it for 10-20 minutes. After the maintenance is over, open the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com