Process of treating and utilizing acid waste water containing heavy metal

A technology for acidic wastewater and heavy metals, applied in water/sewage treatment, water/sludge/sewage treatment, separation methods, etc., can solve problems such as resource waste, environment, pollution, etc., to reduce water consumption, simple operation and maintenance, and reduce effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below in conjunction with accompanying drawing, the present invention will be further described:

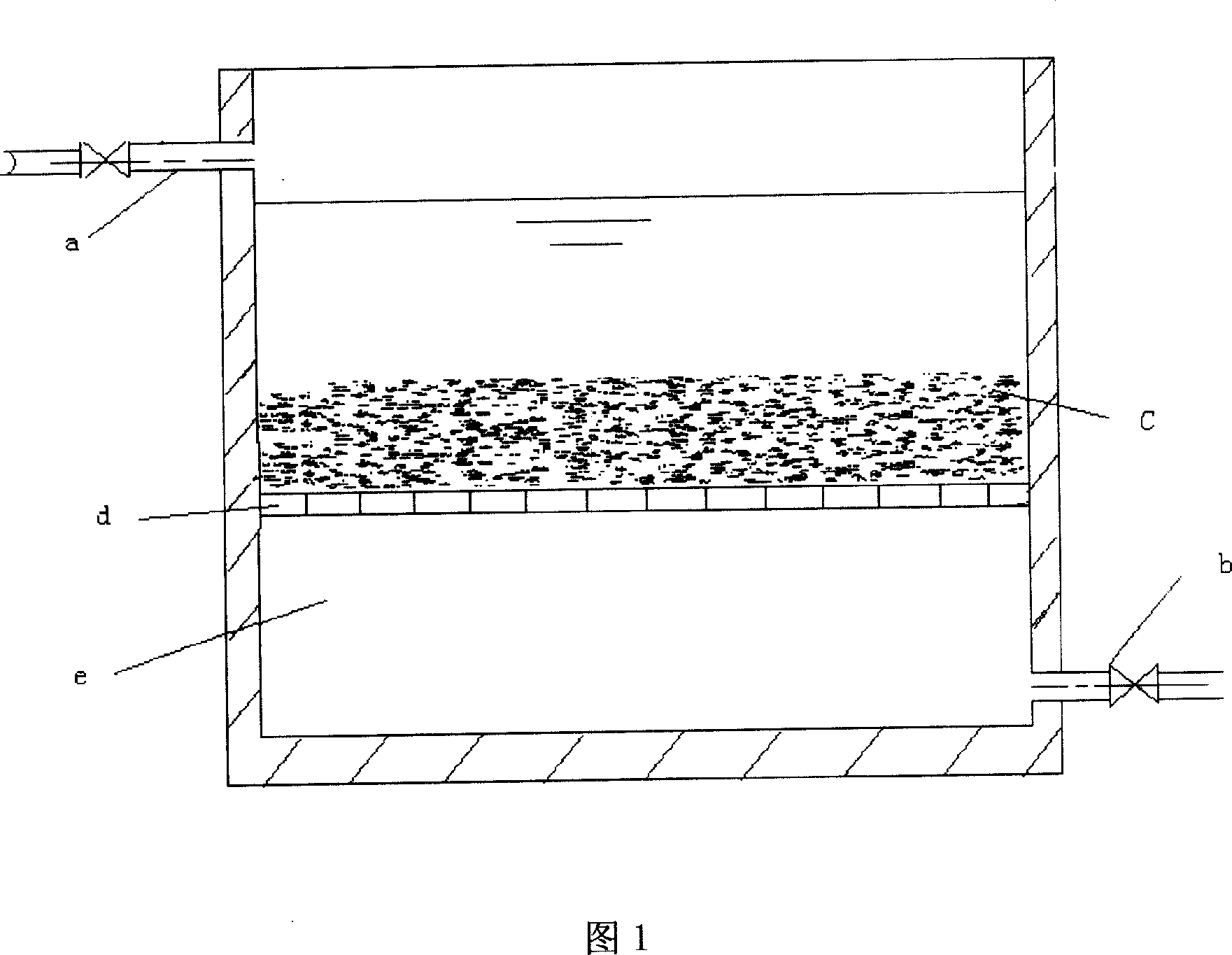

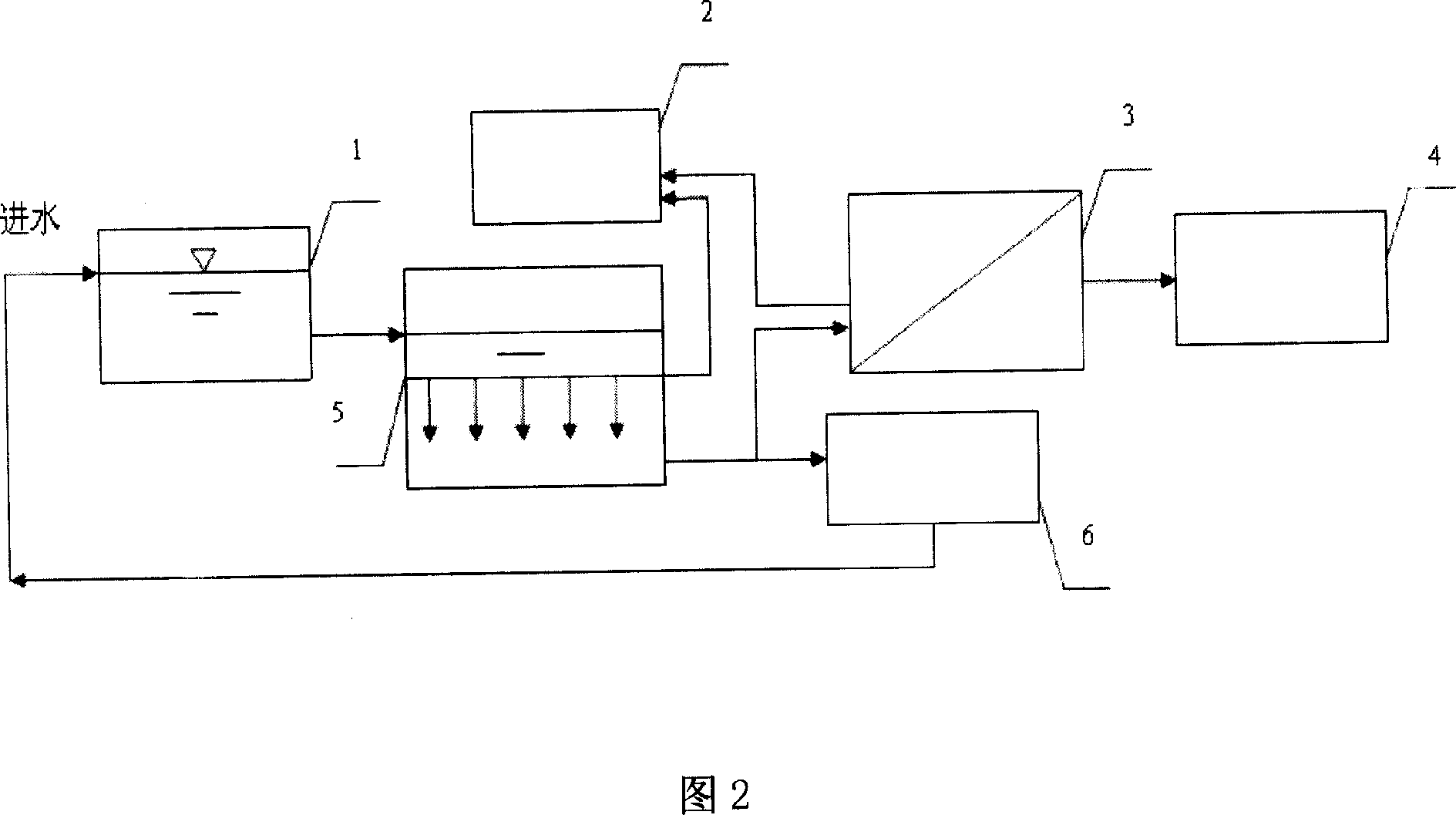

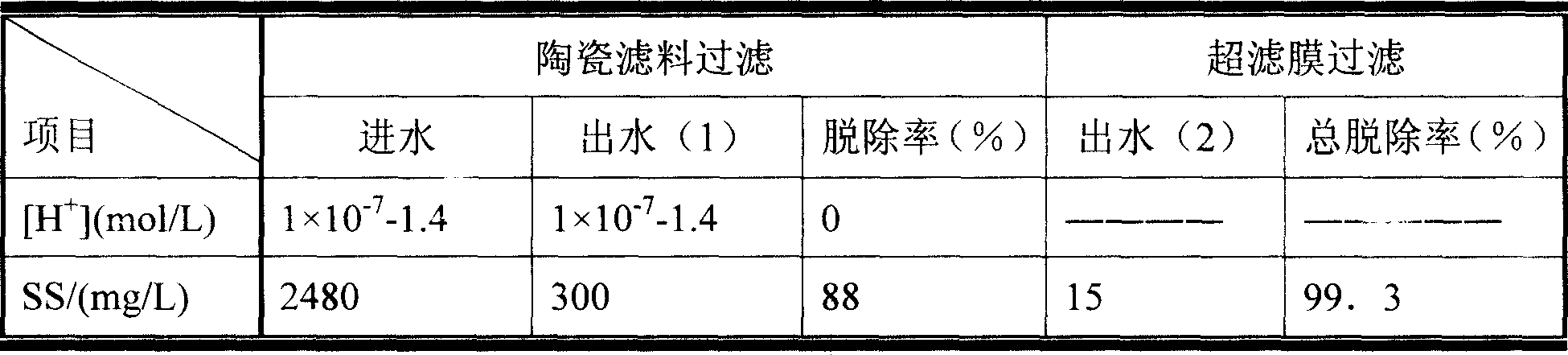

[0047] As shown in Figure 1 and Figure 2, the purification and washing wastewater produced in the production process of smelting flue gas acid production is 80-100m 3 / h, acid containing about 0.7%, total suspended solids (ss) is 2480mg / L, acid waste water containing heavy metals such as Cu, Ni, Pb, Ca, enters the ceramic filter material filter facility 5 after sedimentation in the sedimentation tank 1 to filter. The waste water flows in from the water inlet a on the upper part of the filtration facility, and flows down sequentially through the ceramic filter material layer c and the ceramic filter plate d with a filter material particle size of 2.0mm and a filter layer thickness of 0.70m. At a filtration rate of 6m / h, impurities such as suspended matter in water and macromolecular particles with a particle size between 0.2-1.0mm are mechanically screened through the filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com