Measuring system and screening method for thermal conductivity assembly heat conductivity

A technology of thermal conductivity and measurement system, which is applied in the direction of semiconductor devices, semiconductor/solid-state device parts, electrical components, etc., can solve the problem of low reference value, high manpower and time cost, measurement value reproducibility, resolution and reliability Stability and other issues to achieve stable reproducibility, reduce manpower and time costs, and shorten the measurement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

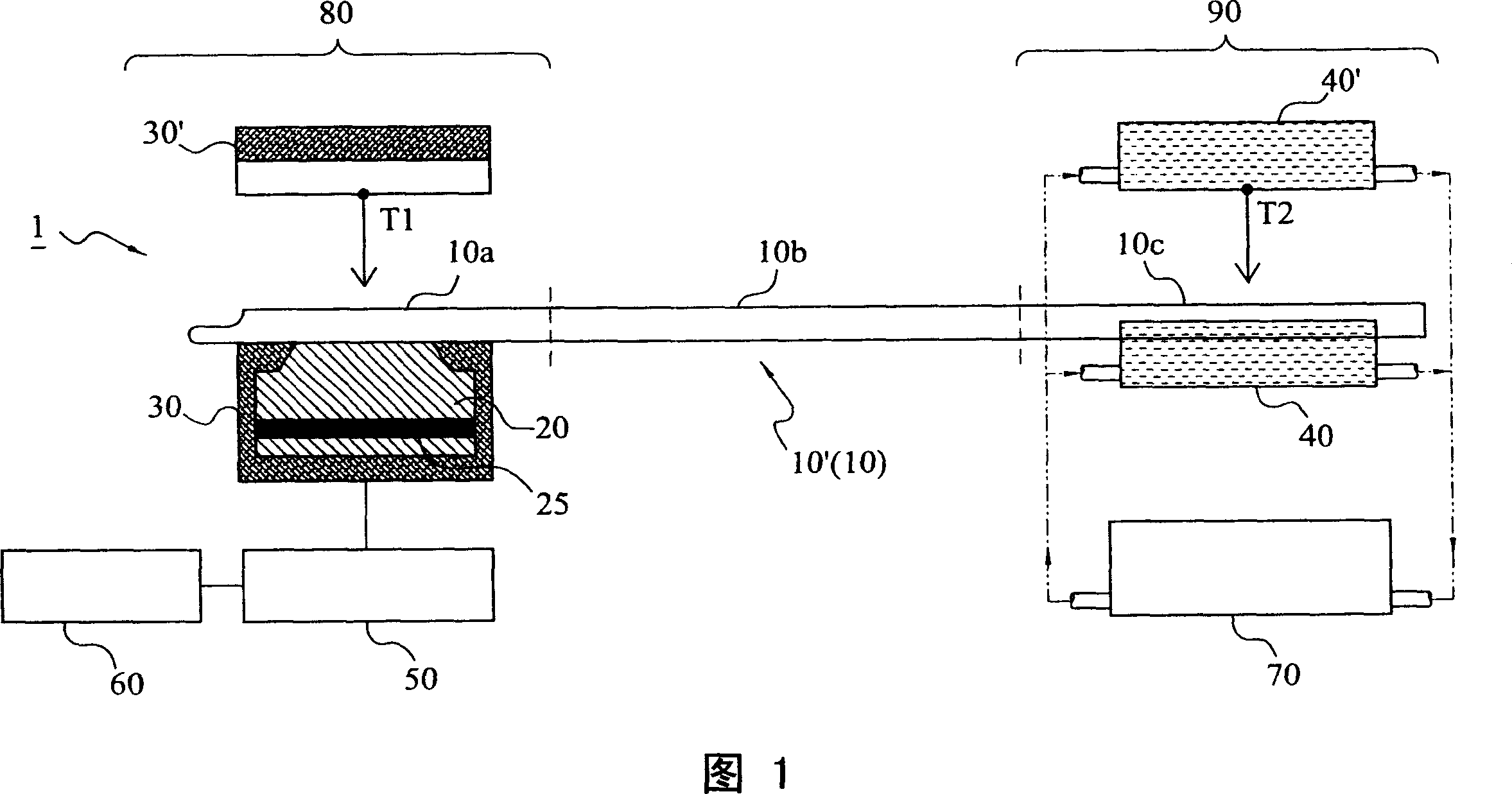

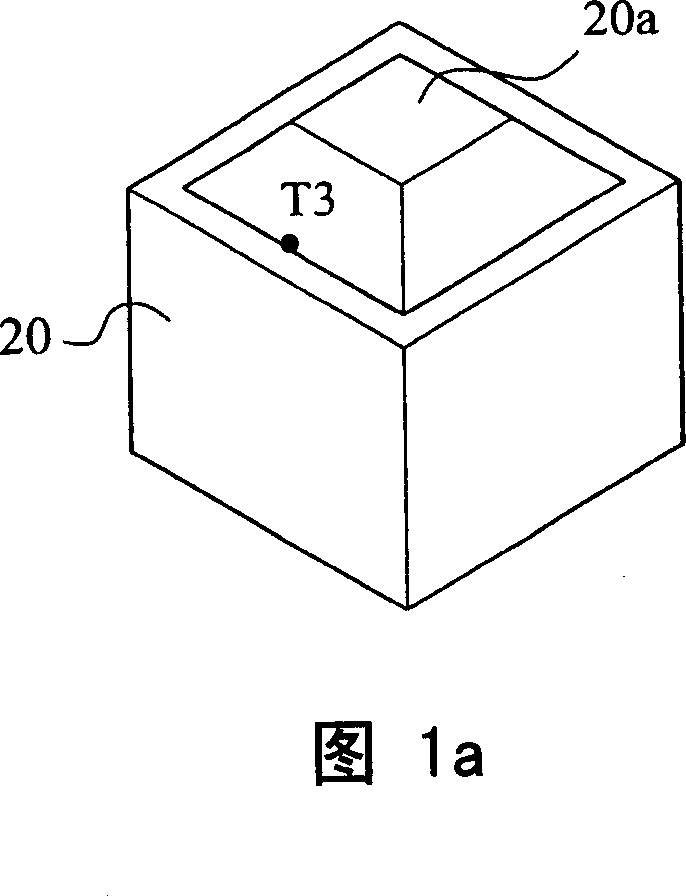

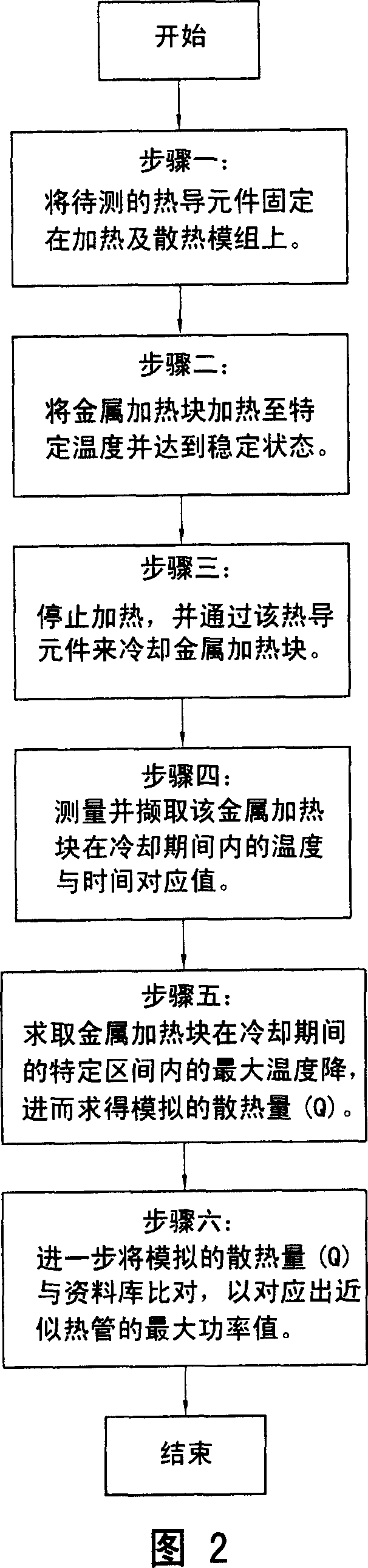

[0023] The measurement system and screening method for the thermal conductivity of thermal conduction components of the present invention are applied to quickly measure the thermal conductivity of thermal conduction components such as heat pipes, vapor chambers, heat sinks, etc., such as: temperature difference ΔT, contact thermal resistance R and maximum Heat transfer Qmax, etc., in order to achieve the purpose of rapid quantification and screening. The following embodiment will further illustrate the technical characteristics of the present invention by taking the heat pipe 10' as the representative object to be tested. This embodiment is only a preferred example and is not used to limit the scope of the present invention. Please refer to the accompanying drawings in conjunction with the following Explain in detail for best understanding.

[0024] First, please refer to FIG. 1, which is a schematic diagram of a measurement system 1 for the thermal conductivity of the thermal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com