Bobbin for superconducting coil, and superconducting solenoid coil

A technology of superconducting coils and superconducting wires, which is applied in the field of solenoid coils and solenoid coils formed with cylinders, and can solve the problems of not proposing the rewinding position, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

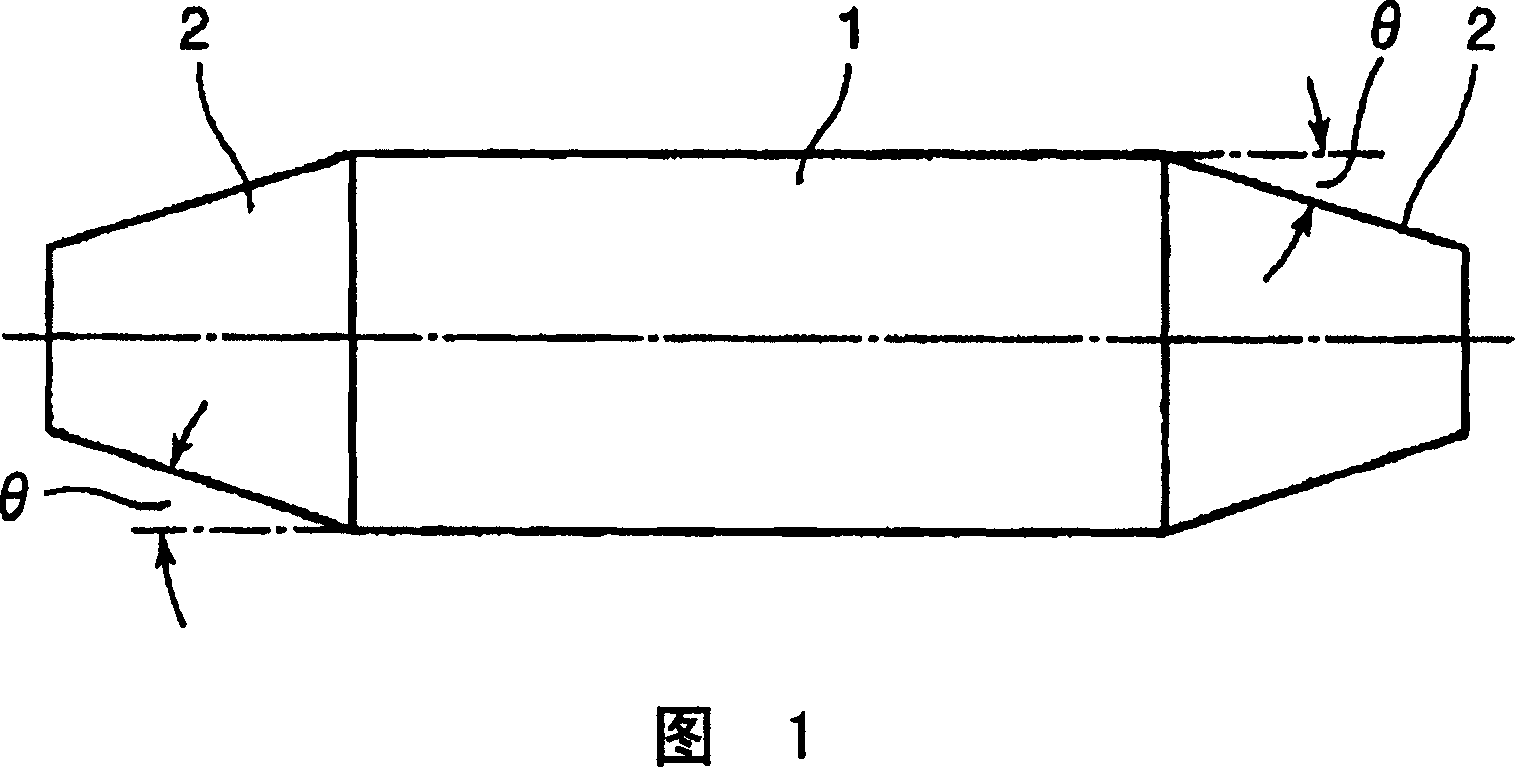

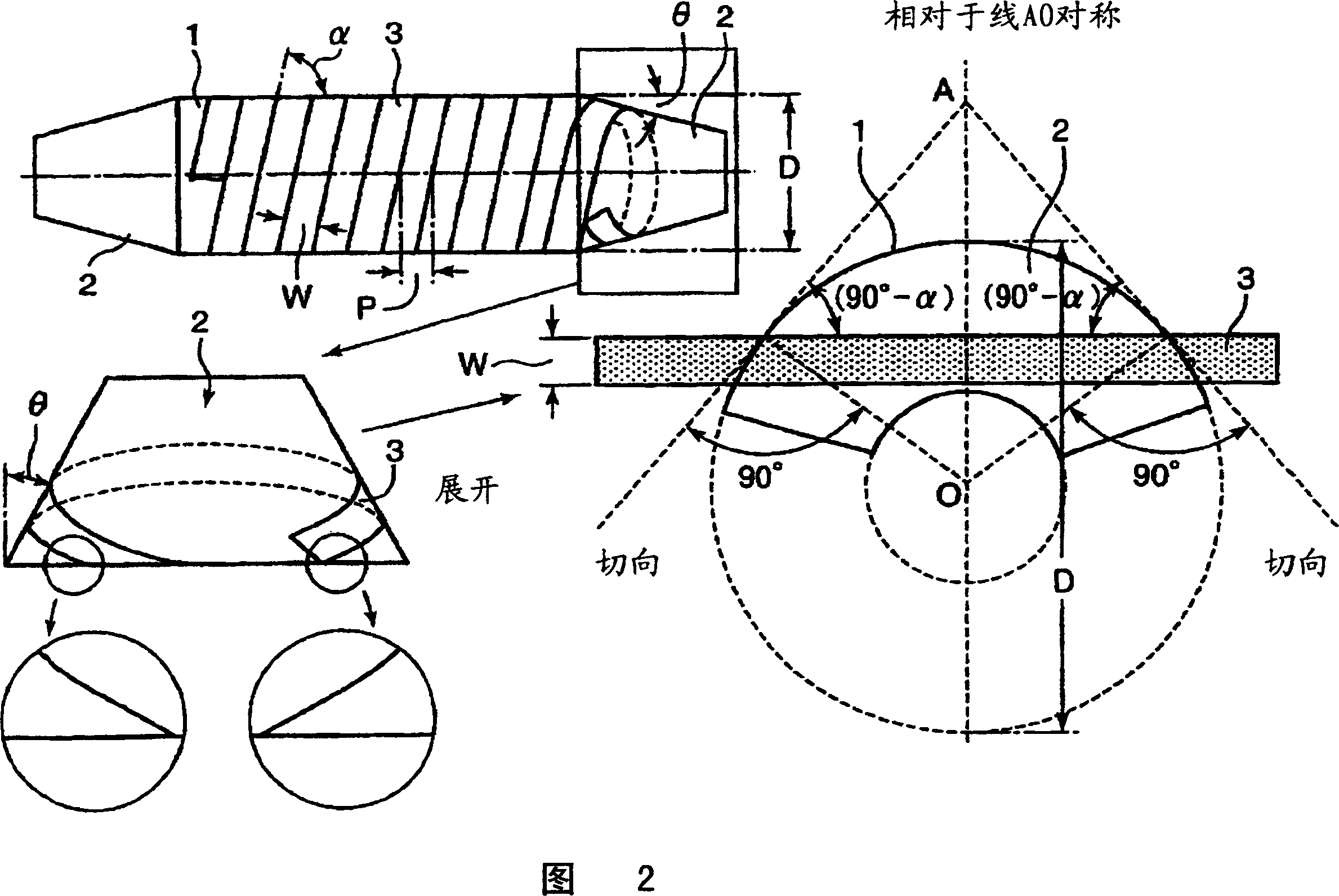

[0047] A ribbon-shaped wire having a width W of 10 mm and a thickness t of 0.2 mm shown in FIG. 8 is tightly and solenoidally wound around a cylinder with a helical winding angle α of 88°, the cylinder having an outer diameter D of a cylindrical portion of 80 mm, The length L of 500 mm and the taper angle θ of 30° allow adjacent windings of the wire not to overlap each other. The wire was wound from one end of the cylindrical portion to the tapered portion at an angle of 88° to form a first layer, and was rewound in close contact with the tapered portion. The tape was then wound around the cylindrical portion at 88° in a direction opposite to that of the first layer, thereby forming a second layer. Therefore, the wire can be smoothly rewound to form the second layer while being in close contact with the tapered portion.

no. 2 example

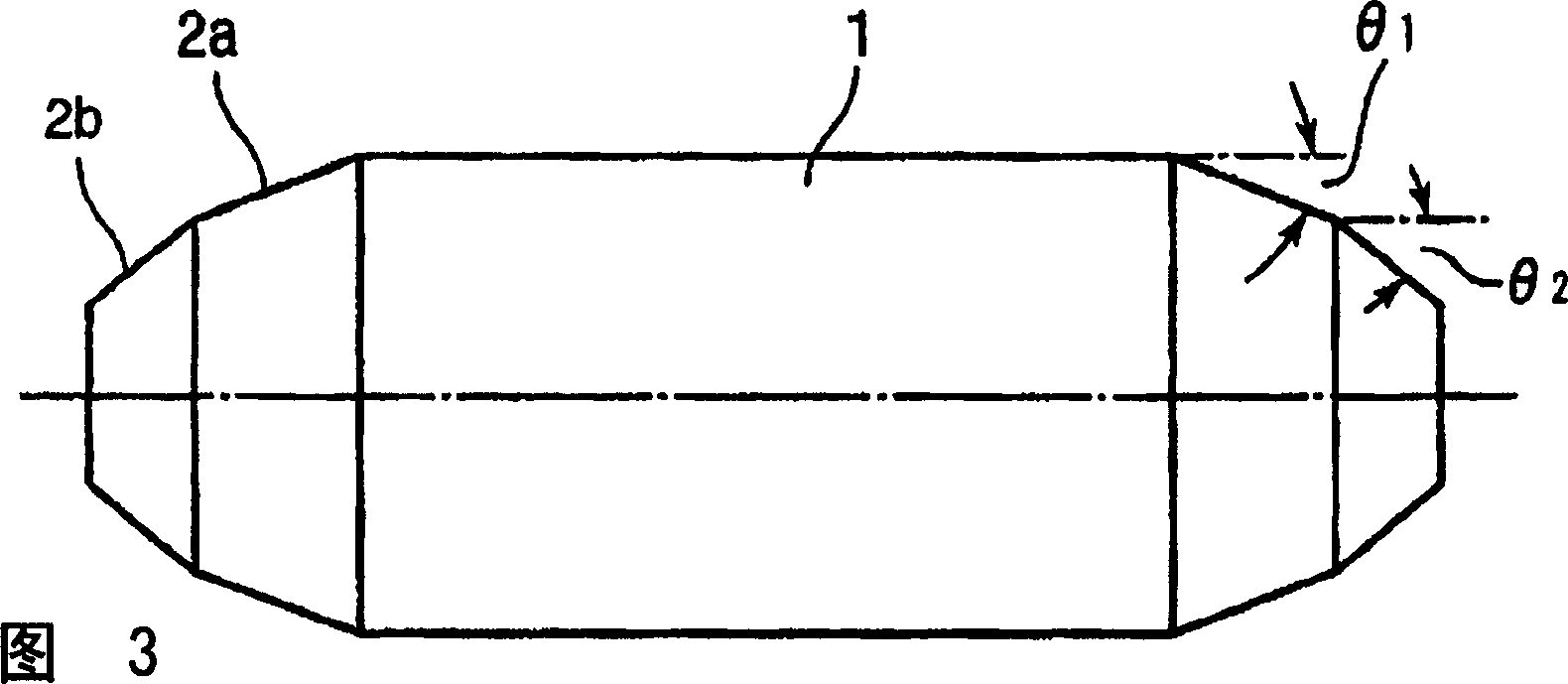

[0049] A ribbon-shaped wire having a width W of 10 mm and a thickness t of 0.2 mm shown in FIG. 10 is tightly and solenoidally wound around a cylinder with an outer diameter D of a cylindrical portion of 80 mm at a helical winding angle α of 88°. The length L of 500 mm and the taper angle θ1 of 10° and the taper angle θ2 of 30° allow adjacent windings of the wire not to overlap each other. The wire is wound from one end of the cylindrical portion to the first tapered portion at an angle of 88° to form the first layer, and is rewound in close contact with the first tapered portion and the second tapered portion, and then wrapped around the cylindrical Parts were wound at 88° in a direction opposite to that of the first layer, thereby forming a second layer. Therefore, the wire can be gently rewound in close contact with the tapered portion to form the second layer.

[0050] When the wire multilayer solenoid is wound, the coil diameter increases step by step, and the winding an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com