Painting device, painting method, and display member provided therefrom

A coating device and coating technology are applied to the device, coating, optics and other directions of coating liquid on the surface to achieve the effects of buffering spit fluctuations, improving film thickness uniformity and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

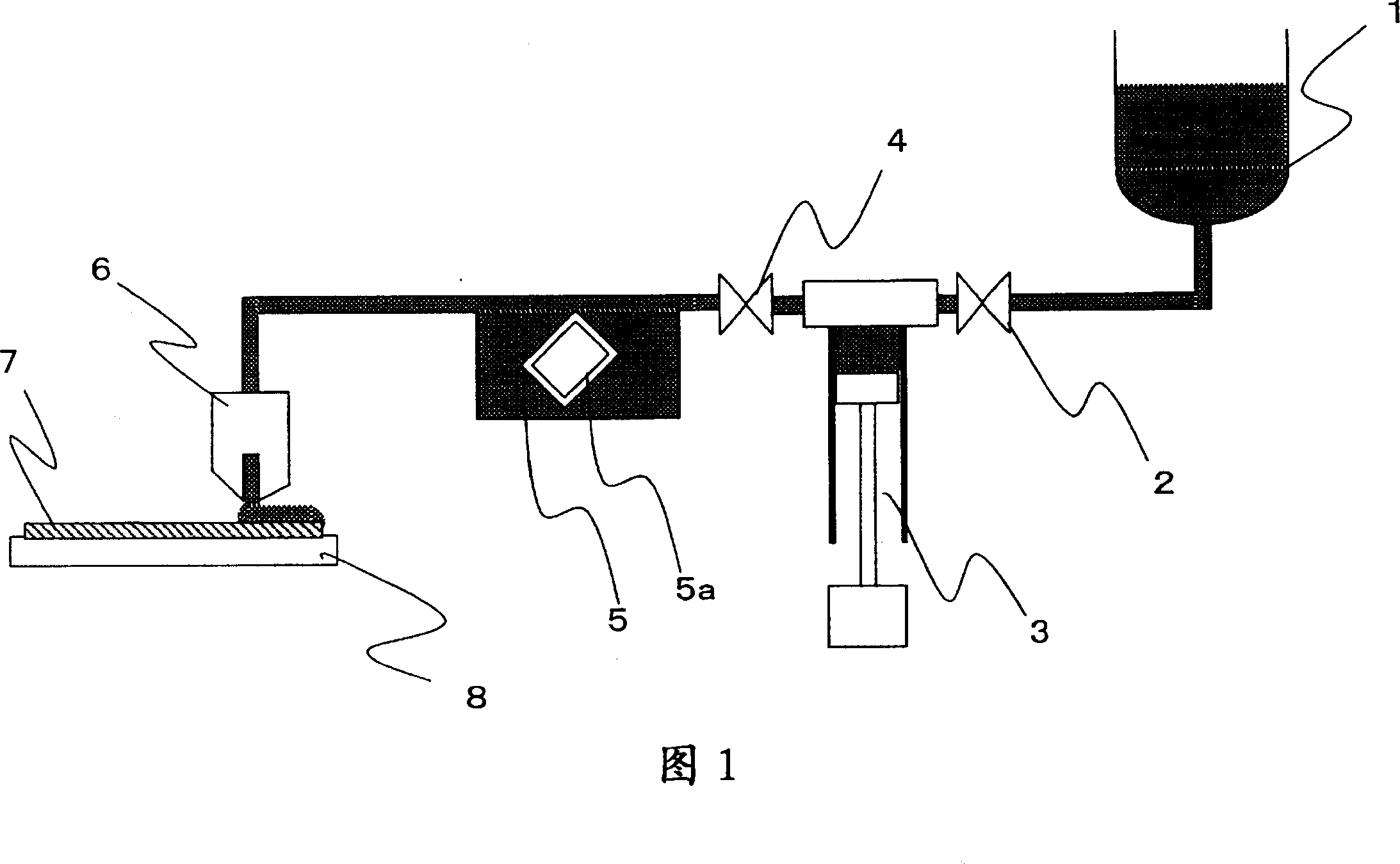

[0132] Fig. 1 shows a flow chart of liquid infusion in a slot die coating apparatus used in this example. A piston type hydraulic pump 3 with an inner diameter of 18 mm was used as a coating liquid supply device, and a die nozzle 6 with a discharge slit width of 620 mm and a slit gap of 100 μm was used as a coating device. In addition, a chamber 5 is provided on the pipe, and this chamber 5 seals a member for buffering discharge fluctuations that eliminates stagnant portions of the coating liquid as much as possible. Oxygen permeability: 800cm 3 / m 2 ・day・MPa) polyethylene sheet is laminated and heat-sealed with a width of 2mm in the outer peripheral part, thereby enclosing 0.8cm 3 parts of the air. The apparent specific gravity of this component is 0.091 times the actual density of the gas-encapsulated material, the wetted area is 100% of the surface area, the flatness index A=1.84, and V / Q=0.343. Use this coating device, on the non-alkali glass substrate of 620 * 750mm, ...

Embodiment 2

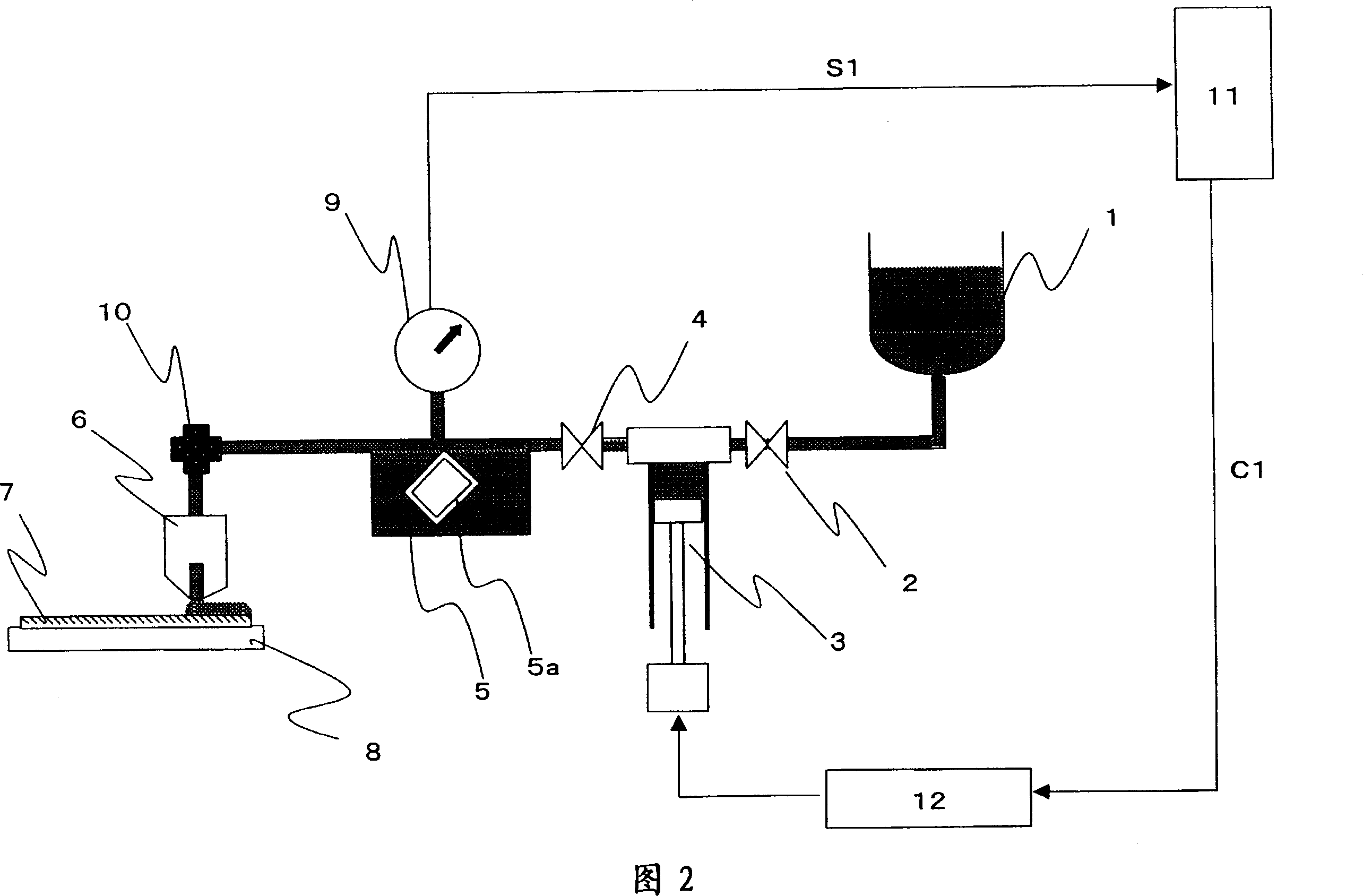

[0144] As shown in the flow chart in Figure 2, a needle valve is set as a device 10 to increase the internal pressure of the pipeline, and the opening of the valve is adjusted until the indicated value of the pressure gauge 9 measuring the pipeline pressure between the coating liquid supply device and the needle valve It was 0.1 MPa, and the coating film formation was performed similarly to Example 1 after that.

[0145] The evaluation results are shown in Table 1.

[0146] A. Uneven interference

[0147] Striped interference unevenness was not seen at all, so it was judged to be excellent.

[0148] B. Average film thickness, coating stability distance, film thickness distribution width

[0149] A coating stability distance of 14 mm is judged to be good (Fig. 5-c).

[0150] In the stable coating range, the film thickness distribution width R = 0.004 μm, which is greatly improved compared with Example 1, and judged to be excellent (Fig. 5-d).

[0151] C. Continuous use perf...

Embodiment 3

[0156] As shown in the flow chart in Figure 2, a gas barrier sheet with a size of 20×20mm and a thickness of 112μm (Mitsubishi Gas Chemical Co., Ltd. PTS bag: 5cm 3 / m 2 ·day·MPa) was used as a material for enclosing gas in the member 5a that buffers discharge fluctuations, and a coating film was formed in the same manner as in Example 2. The apparent specific gravity of this part is 0.107 times the actual density of the gas-encapsulated material, the wetted area ratio is 100% of the surface area, the flatness index A=1.82, and V / Q=0.350.

[0157] The evaluation results are shown in Table 1.

[0158] A. Uneven interference

[0159] Strip unevenness was not seen at all, and it was judged as excellent.

[0160] B. Average film thickness, coating stability distance, film thickness distribution width

[0161] The coating stability distance was 14 mm, which was judged to be good.

[0162] In the stable coating range, the film thickness distribution width was R=0.004 μm, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com