Technological method of water-coke slurry for glass melting kiln

A glass melting furnace and process method technology, applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools and other directions, can solve problems such as unreported, and achieve the effects of saving oil resources, being conducive to environmental protection, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

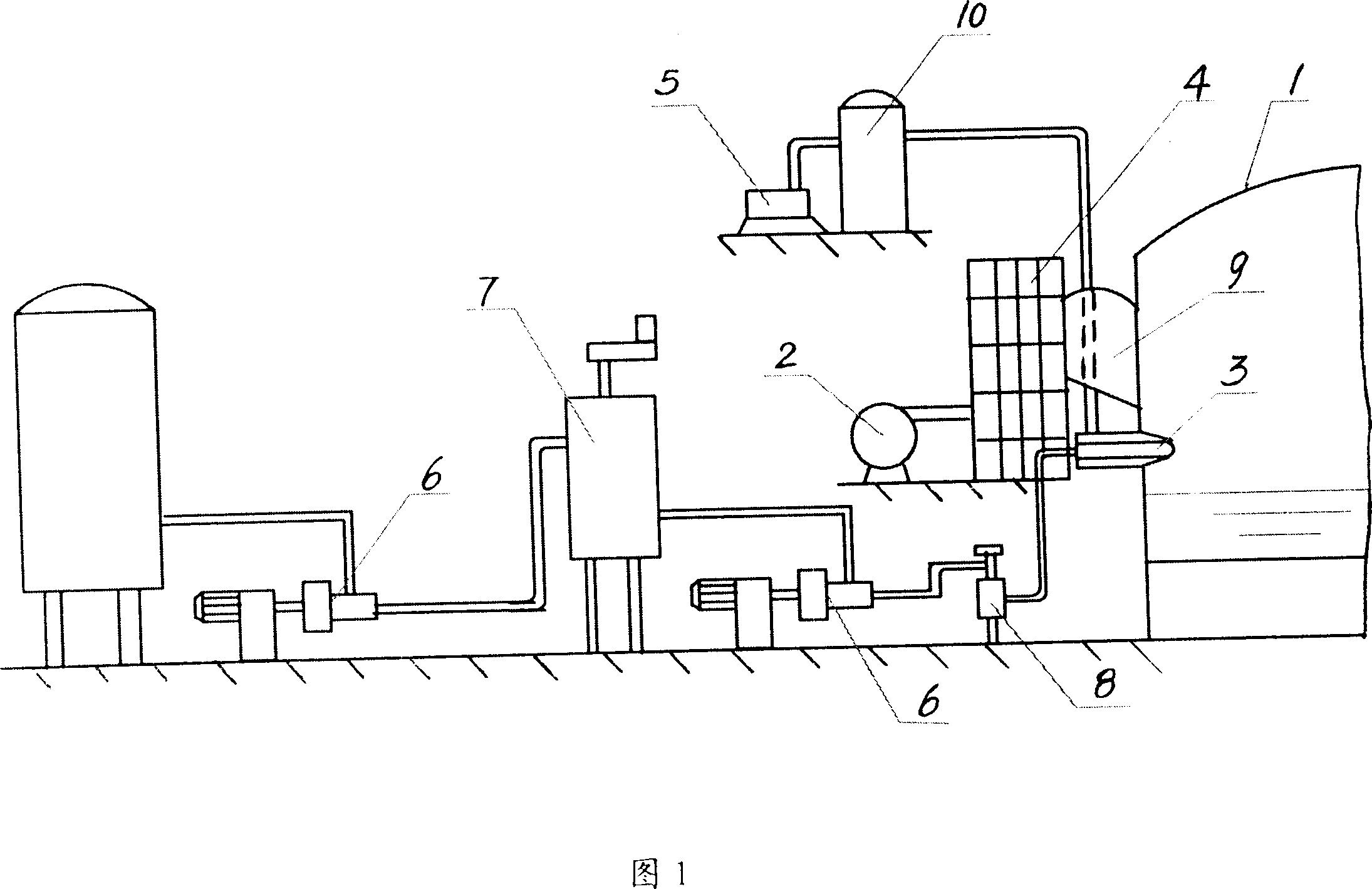

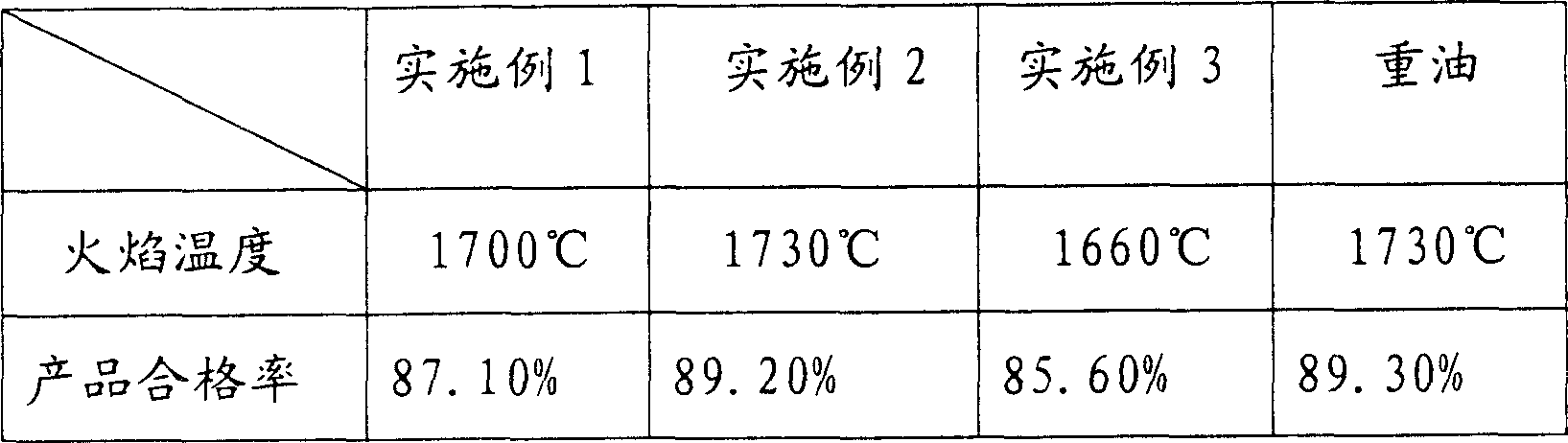

[0021] Embodiment 1, adopt the hydrocoke slurry that contains 45% petroleum coke, after the single screw pump 6 is pressurized, fully stir through the agitator 7 evenly and input in the filter 8 to filter, then the coke slurry is sent to the coke slurry spray gun 3 and make the pressure of the water coke slurry in the water coke slurry spray gun 3 be regulated in the range of 0.2-0.5Mpa, meanwhile, input the rated pressure into the water coke slurry spray gun 3 through the air storage tank 10 with 40 cubic meters of air compressor 5 The compressed air is 0.8Mpa, so that the pressure of the compressed air in the water coke slurry spray gun 3 is adjusted within the range of 0.3-0.8Mpa. Under the action of compressed air, the water coke slurry is atomized by the water coke slurry spray gun 3 and sprayed into the glass melting In the flame space of kiln 1, the combustion-supporting air provided by the blower 2 is heated to 1400-1520°C by the regenerator 4, and then sent into the fl...

Embodiment 2

[0022] Embodiment 2, adopt the hydrocoke slurry that contains 60% petroleum coke, after the single screw pump 6 is pressurized, fully stir through agitator 7 evenly and input in the filter 8 to filter, then the coke slurry is sent to the coke slurry spray gun 3 and make the pressure of the water coke slurry in the water coke slurry spray gun 3 be regulated in the range of 0.4-0.7Mpa, meanwhile, input the rated pressure into the water coke slurry spray gun 3 through the air storage tank 10 with 40 cubic meters of air compressor 5 The compressed air is 1.2Mpa, so that the pressure of the compressed air in the water coke slurry spray gun 3 is adjusted within the range of 0.5-1Mpa. Under the action of compressed air, the water coke slurry is atomized by the water coke slurry spray gun 3 and sprayed into the glass melting furnace In the flame space of 1, the combustion-supporting air provided by the blower 2 is heated to 1300-1500°C by the regenerator 4, and then sent into the flame...

Embodiment 3

[0023] Embodiment 3, adopt the hydrocoke slurry that contains 75% petroleum coke, after the single screw pump 6 is pressurized, fully stir through the agitator 7 evenly and input in the filter 8 to filter, then the coke slurry is sent to the coke slurry spray gun 3 and make the pressure of the water coke slurry in the water coke slurry spray gun 3 be regulated in the range of 0.5-1.2Mpa, meanwhile, input the rated pressure into the water coke slurry spray gun 3 through the air storage tank 10 with 40 cubic meters of air compressor 5 The compressed air is 1.5Mpa, so that the pressure of the compressed air in the water coke slurry spray gun 3 is adjusted within the range of 0.6-1.5Mpa. Under the action of compressed air, the water coke slurry is atomized by the water coke slurry spray gun 3 and sprayed into the glass melting In the flame space of kiln 1, the combustion-supporting air provided by blower 2 is heated to 800-1200°C by regenerator 4, and then sent into the flame space...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com