Hardening oil on-line dehydration apparatus

A technology of dehydration device and quenching oil, applied in the direction of flash evaporation, lubricating composition, etc., can solve the problems of inability to run online, not yet discovered, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

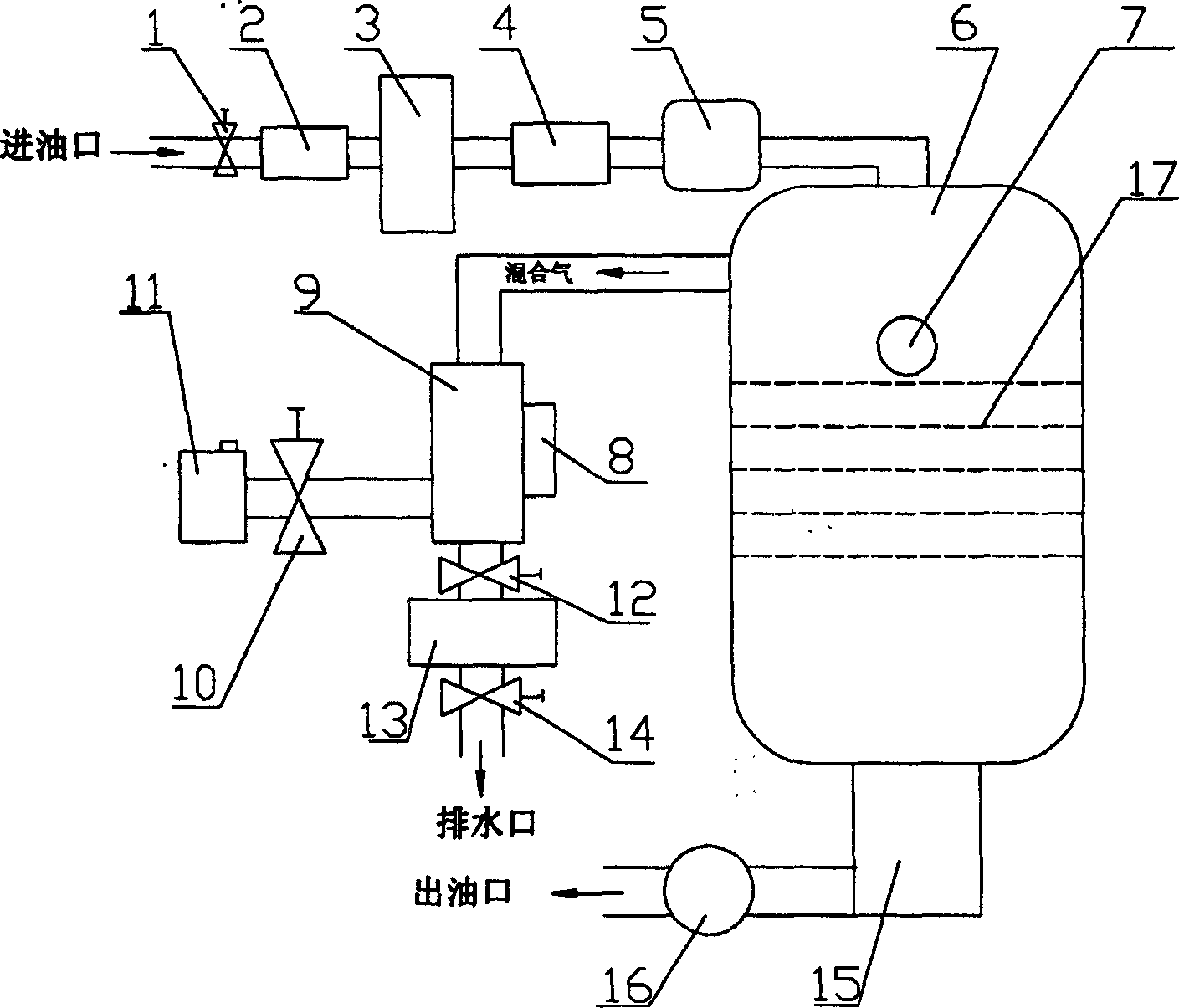

[0011] As shown in Figure 1, the present invention comprises: oil inlet control valve 1, pre-filter 2, heater 3, secondary filter 4, anti-foam device 5, vacuum tank 6, pressure sensor 7, cooling fan 8, cooling Device 9, first vacuum valve 10, vacuum pump 11, second vacuum valve 12, water reservoir 13, third vacuum valve 14, three-stage filter 15, oil pump 16 and flash plate 17. The connection method is as follows: an oil inlet control valve 1 is installed at the oil inlet, a pre-filter 2 and a secondary filter 4 are respectively installed before and after the heater 3, a thermocouple is installed inside the heater 3, and a vacuum tank 6 and a secondary filter are installed. An anti-foamer 5 is arranged between the stage filters 4, a pressure sensor 7 and a flash plate 17 are arranged in the vacuum tank 6, a vacuum valve 10 is arranged between the vacuum pump 11 and the cooler 9, and a cooling fan 8 and a lower part are arranged on the side of the cooler 9. Water reservoir 13 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com