Integral quenching type land leveller blade manufacturing method and quenching die

A technology of overall quenching and manufacturing methods, which is applied in the direction of manufacturing tools, quenching devices, furnace types, etc., can solve the problems that affect the reliability of the motor grader, the service life of the blade is not long, and it cannot be used normally, so as to improve the reliability of the whole machine Sex and construction efficiency, high production efficiency, and short manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

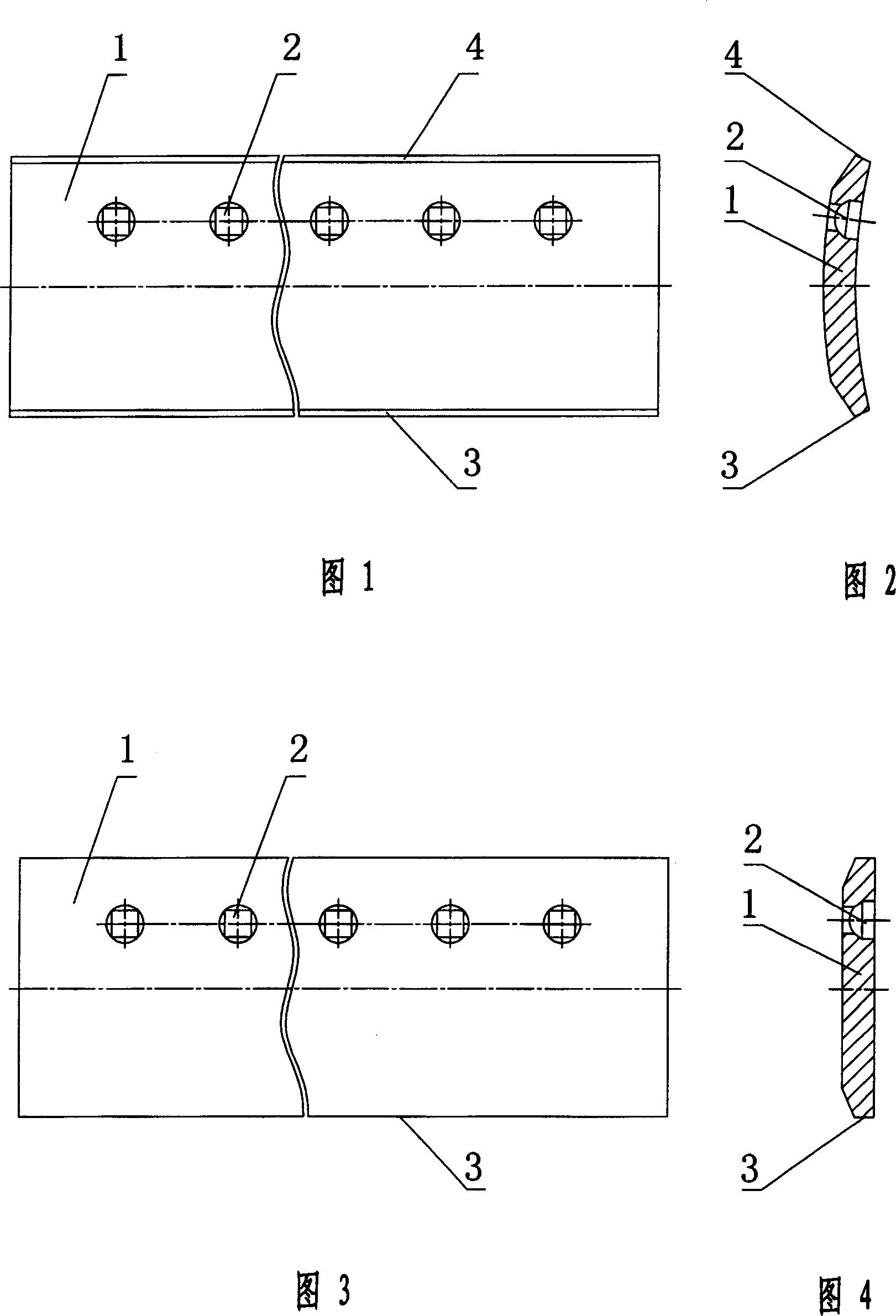

[0033] Embodiment 1: A kind of overall quenching process of the shovel blade of a grader. The blade material is 65Mn alloy steel. First, the 65Mn raw material is processed into a shovel blade of a grader, and then the blade is hot-pressed, integrally quenched and tempered. The specific steps For: (1). Hot press forming, overall quenching: heat the blade to 800°C and put it into the quenching mold, press the quenching mold with a pressure machine to the set pressure parameter of 3.0×10 6 ~4.0×10 6 N, and then pass quenching oil with a temperature of 20°C into the quenching mold to quench the blade; hot pressing forming and overall quenching are completed at the same time; (2). Tempering treatment: put the blade that has completed step 1) into the back In the furnace, after heating to 280°C, keep it warm for 120 minutes, and then take it out of the furnace and air cool. The grader shovel blade hardness after the above treatment is 52-57HRC.

[0034] The quenching mold used in ...

Embodiment 2

[0035] Example 2: First process the 65Mn raw material into a grader shovel blade, and then perform hot-press forming, overall quenching and tempering treatment. The specific steps are: (1). Hot-press forming, overall quenching: after the blade is heated to 810°C Put it into the quenching mold, press the quenching mold with a pressure machine to the set pressure parameter 3.0×10 6 ~4.0×10 6 N, and then pass quenching water with a temperature of 30°C into the quenching mold to quench the blade; hot pressing forming and overall quenching are completed at the same time; (2). Tempering treatment: put the blade that has completed step (1) into the back In the furnace, after heating to 400°C, keep it warm for 100 minutes, and then take it out of the furnace and air cool. The grader blade hardness after the above treatment is 43-48HRC.

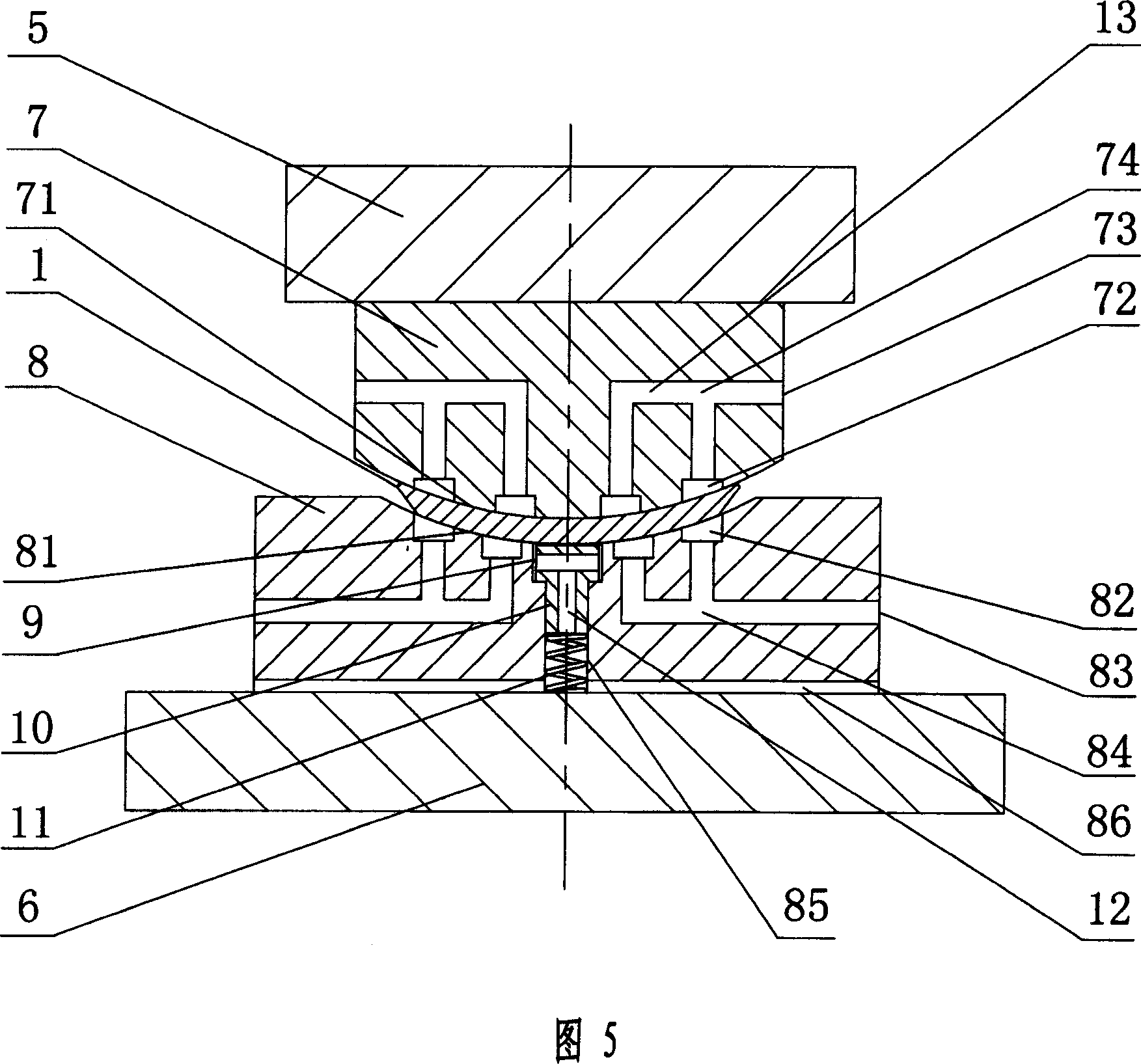

[0036] The quenching mold used in the present embodiment, as shown in Figure 5, comprises upper mold 7, lower mold 8, upper mold base 5 and lower m...

Embodiment 3

[0037] Example 3: first process the 65Mn raw material into a grader bulldozer blade, and then carry out hot pressing forming, overall quenching and tempering treatment. The specific steps are: 1 hot pressing forming, overall quenching: heat the blade to 820°C and put into the quenching mold, press the quenching mold with a pressure machine to the set pressure parameter of 2.0×10 6 ~3.0×10 6N, and then pass quenching water with a temperature of 40°C into the quenching mold to quench the blade; hot pressing forming and overall quenching are completed at the same time; 2 Tempering treatment: put the blade that has completed step 1) into the tempering furnace, heat After reaching 430°C, keep it warm for 90 minutes, and then take it out of the oven and air cool. The hardness of the grader blade after the above treatment is 40-45HRC.

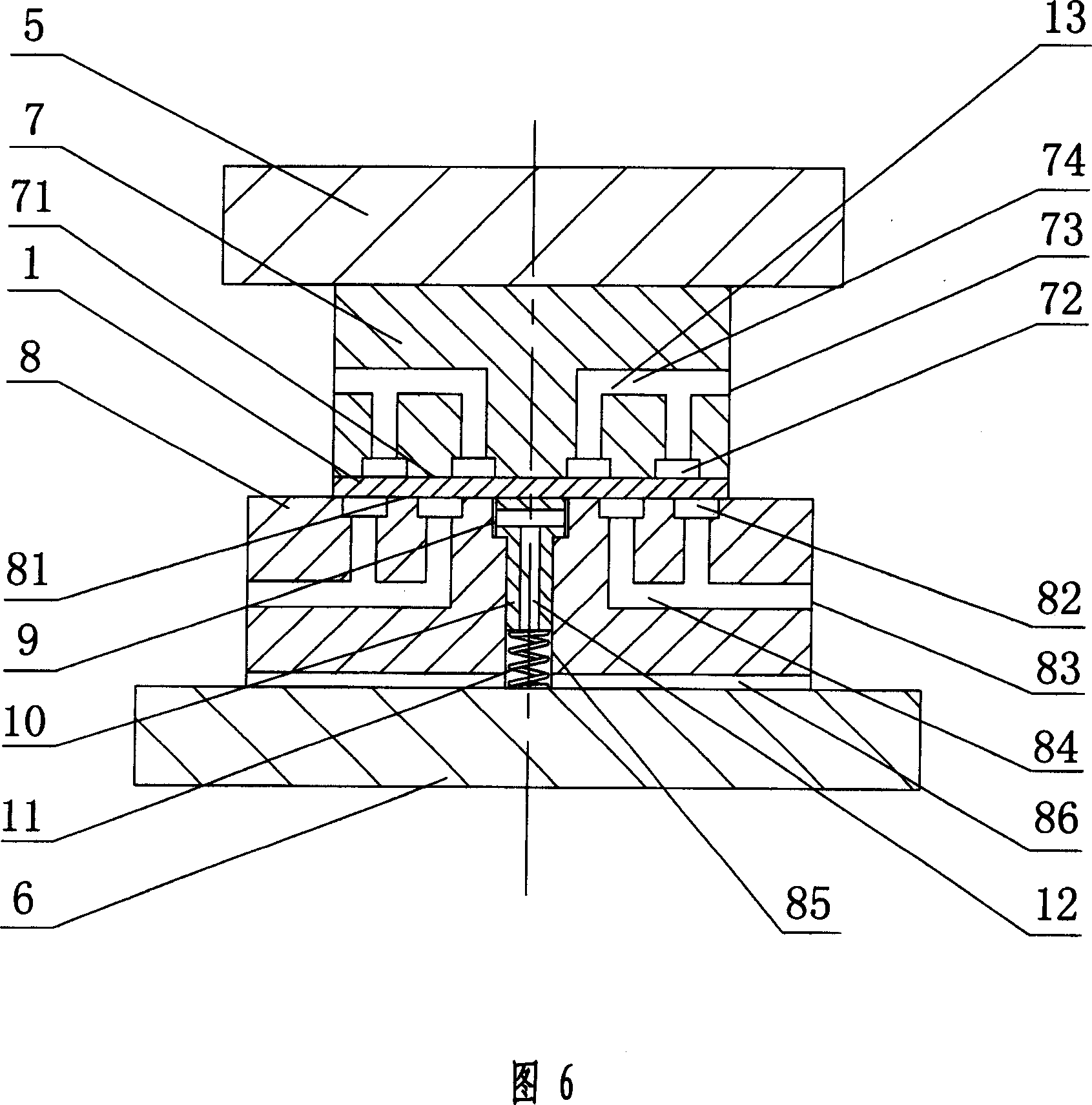

[0038] The quenching mold used in the present embodiment, as shown in Figure 6, comprises upper mold 7, lower mold 8, upper mold base 5 and lower m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com