Silver-containing antibacterial viscose fiber and its preparing method

A technology of viscose fiber and silver nanometer, which is applied in the direction of fiber chemical characteristics, artificial filament made of viscose, artificial silk manufacturing, etc. It can solve the problems of poor antistatic property, failure to achieve antibacterial purpose, and decreased antibacterial property.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

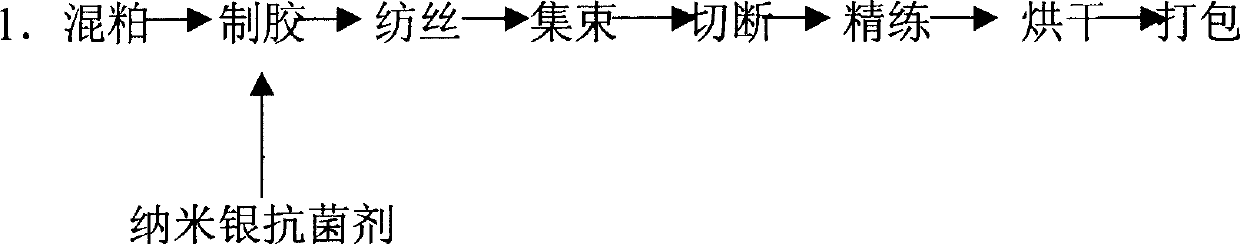

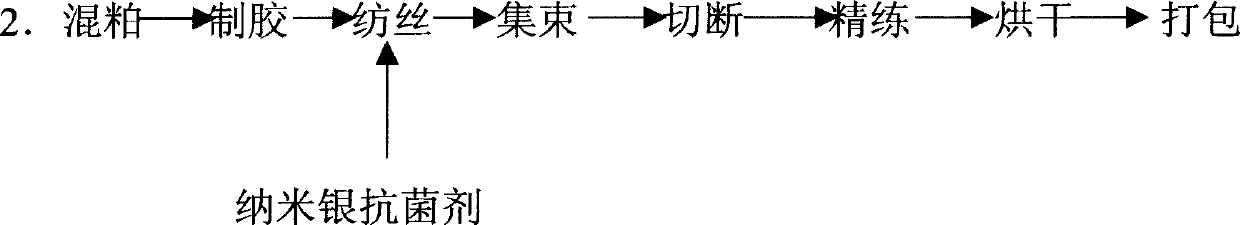

Method used

Image

Examples

Embodiment 1

[0032] (1) Impregnation: The immersion temperature is 45°C, the concentration of lye is 225g / L, and the immersion time is 70 minutes.

[0033] (2) Pressing: the content of methyl fiber is 26%, and the content of sodium hydroxide is 14.5%.

[0034] (3) Mature: temperature 55°C.

[0035] (4) Yellowing: the amount of carbon disulfide is 36%, the initial temperature is 32°C, the final temperature is 40°C, and the time is 150 minutes

[0036] (5) Dissolution: the content of methyl fiber is 8.5%, and the content of sodium hydroxide is 5.3%.

[0037] (6) Spinning: acid bath composition: sulfuric acid 125g / L sodium sulfate 330g / L zinc sulfate 10.5g / L temperature 51°C.

[0038] (7) The amount of nano-silver particles added: 0.6%‰ (based on the amount of methyl cellulose). Particle size: 55 nm.

[0039] (8) Finished product quality: antibacterial value: 3.57 sterilization value: 1.38

[0040] Dry breaking strength: 2.26CN / dtex Wet breaking strength: 1.34CN / dtex

[0041] Dry elonga...

Embodiment 2

[0044] (1) Impregnation: The impregnation temperature is 50°C, the concentration of lye is 235g / L, and the impregnation time is 60 minutes.

[0045] (2) Pressing: the content of methyl fiber is 27%, and the content of sodium hydroxide is 15%.

[0046] (3) Mature: temperature 50°C.

[0047] (4) Yellowing: the amount of carbon disulfide is 38%, the initial temperature is 35°C, the final temperature is 42°C, and the time is 45 minutes.

[0048] (5) Dissolving: the content of methyl fiber is 9.00%, and the content of sodium hydroxide is 5.70%.

[0049] (6) Spinning: acid bath composition: sulfuric acid 130g / L, sodium sulfate 335g / L, zinc sulfate 11g / L, temperature 50°C.

[0050] (7) The amount of nano-silver particles added: 2‰ (based on the amount of methyl fiber). Particle size: 60 nm.

[0051] (8) Finished product quality: antibacterial value: 3.68 sterilization value: 1.57

[0052] Dry breaking strength: 2.35CN / dtex Wet breaking strength: 1.41CN / dtex

[0053]Dry elongati...

Embodiment 3

[0056] (1) Impregnation: The immersion temperature is 55°C, the concentration of lye is 235g / L, and the immersion time is 60 minutes.

[0057] (2) Pressing: the content of methyl fiber is 28%, and the content of sodium hydroxide is 15.5%.

[0058] (3) Mature: Temperature 45°C

[0059] (4) Yellowing: the amount of carbon disulfide is 40%, the initial temperature is 35°C, the final temperature is 40°C, and the time is 40 minutes.

[0060] (5) Dissolution: the content of methyl fiber is 9.5%, and the content of sodium hydroxide is 6.0%.

[0061] (6) Spinning: acid bath composition: sulfuric acid 135g / L, sodium sulfate 340g / L, zinc sulfate 11.5g / L, temperature 49°C.

[0062] (7) The amount of nano-silver particles added: 4‰ (based on the amount of methyl fiber). Particle size: 60 nm.

[0063] (8) Finished product quality: antibacterial value: 3.85 sterilization value: 1.73

[0064] Dry breaking strength: 2.41CN / dtex Wet breaking strength: 1.43CN / dtex

[0065] Dry elongation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com