Half-module chip integrated waveguide 90 degree three-decibel directional coupler

A half-mode substrate integration and directional coupler technology, applied in waveguide devices, electrical components, connecting devices, etc., can solve the problems of high cost, difficult processing, large radiation loss, etc., and achieve small size and low processing difficulty , The effect of small phase difference fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

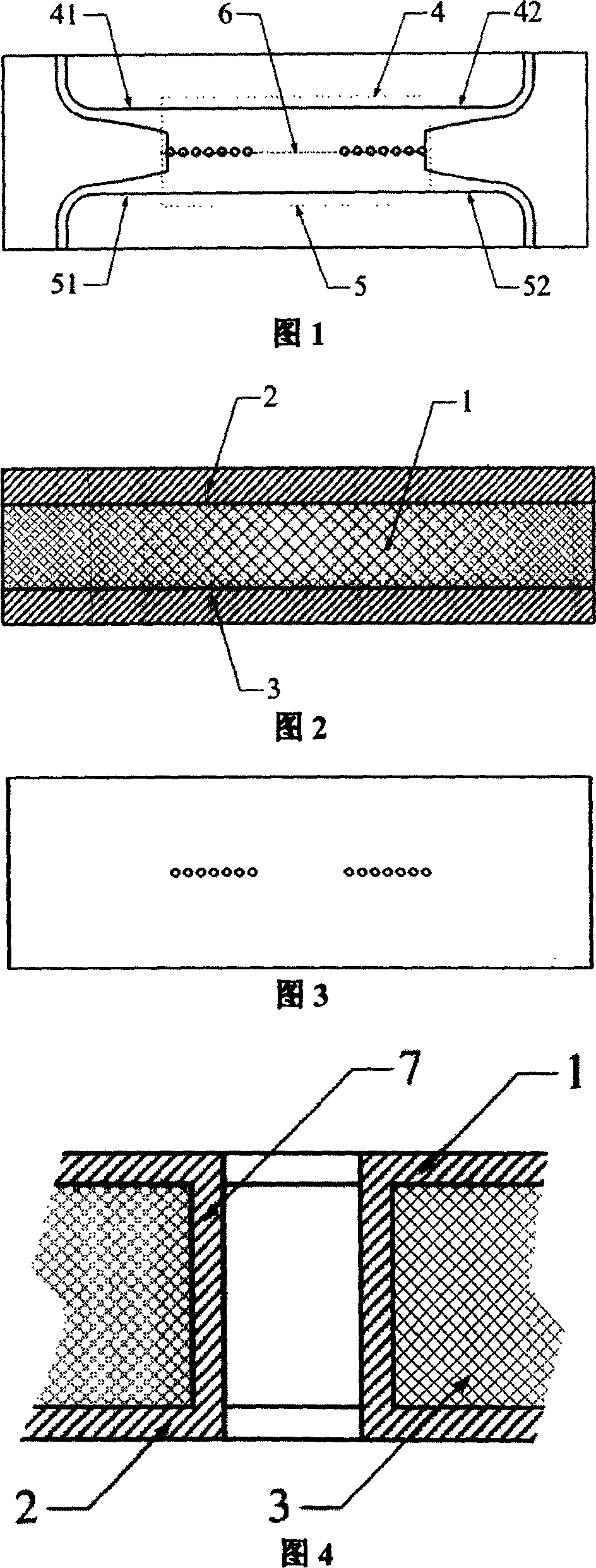

[0021] A half-mode substrate integrated waveguide 90-degree three-decibel directional coupler related to millimeter wave and microwave devices described in this embodiment.

[0022] Referring to Fig. 2, this embodiment includes a dielectric substrate 1 covered with metal patches 2, 3 on both sides;

[0023] 1 and 3, on one side of the metal patch 2 are provided with an input terminal 41, an output terminal 42, an isolation terminal 51 and a coupling terminal 52, between the input terminal 41, the output terminal 42 and the isolation terminal 51, the coupling terminal 52 Metallized through-holes and coupling slots 6 arranged in rows are arranged between them. With such a structure, two half-mode substrate integrated waveguides 4, 5 are formed on the dielectric substrate 1 covered with metal patches 2, 3 on both sides, and two ends of one of the half-mode substrate integrated waveguides 4 are respectively set There is an input terminal 41 and an output terminal 42, and an isola...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com