Cascade optical parameter oscillating laser

An optical parametric oscillation and laser technology, applied in the field of lasers, can solve the problems of high cost and complex structure, and achieve the effects of low cost, high utilization efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

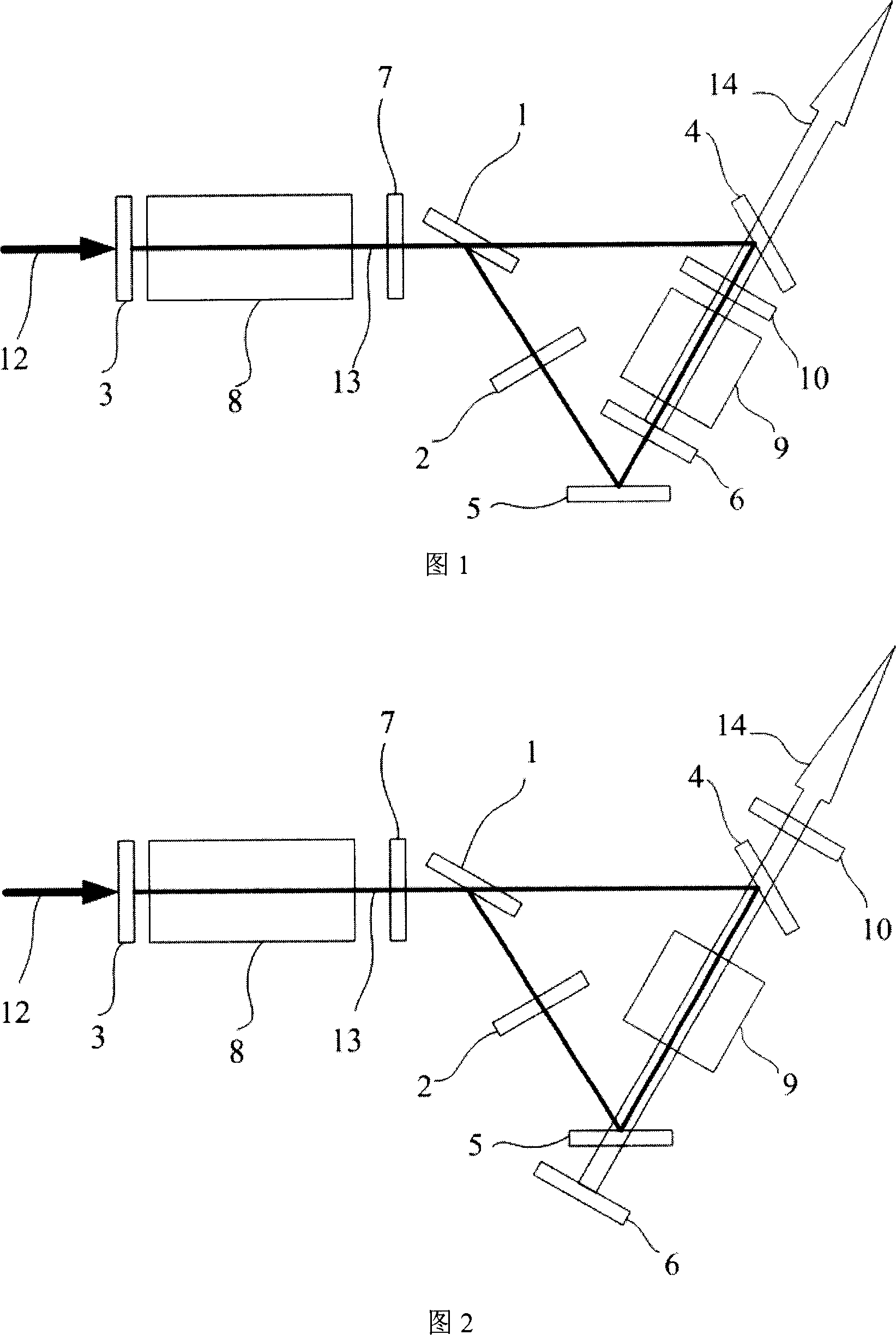

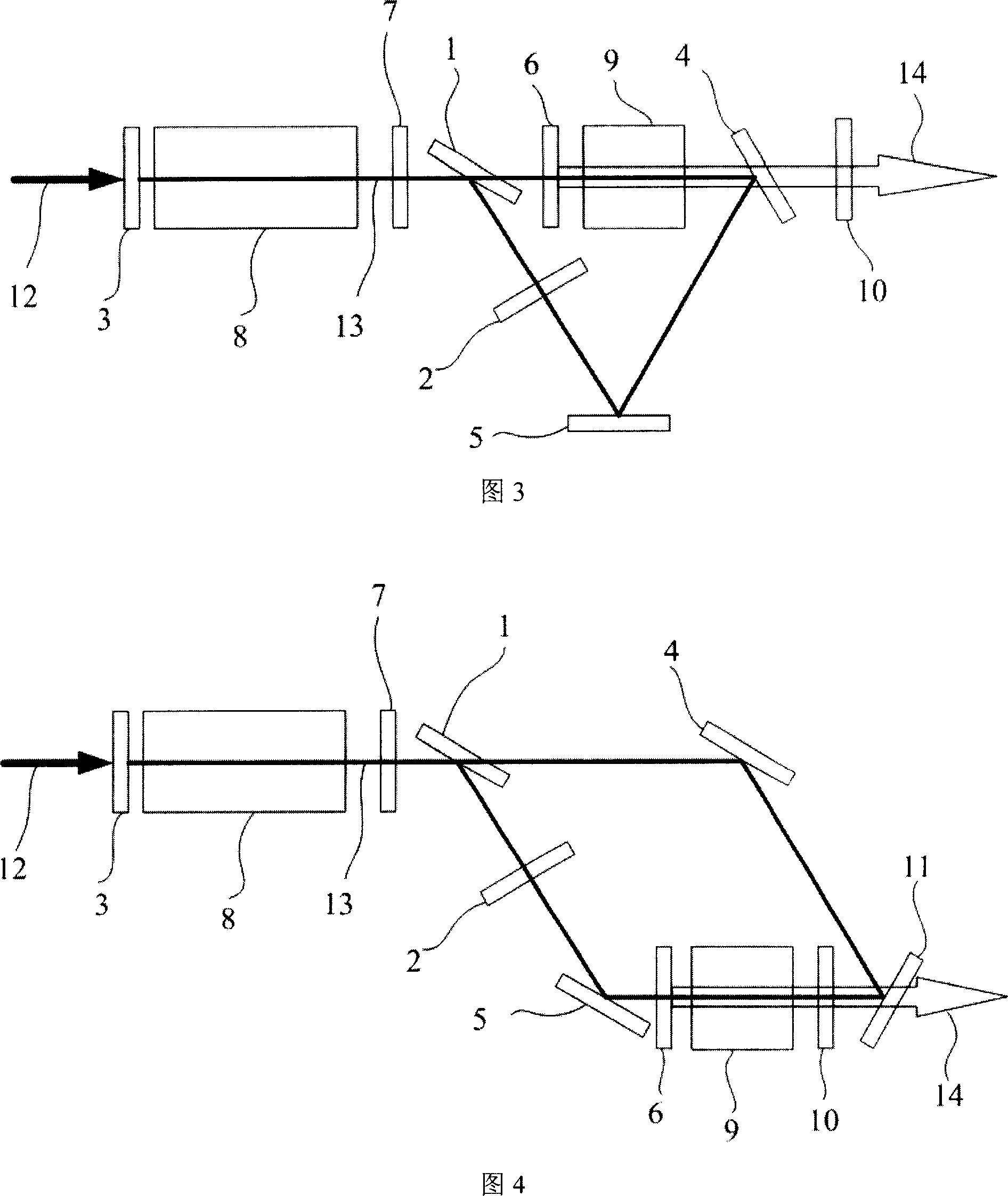

[0022] The first embodiment of the cascaded OPO of the present invention, as shown in FIG. 1 , includes a first-stage OPO, a second-stage OPO, and a polarized light recycling resonant cavity. Components in the above three parts share phenomenon. The first-stage OPO is degenerate or near-degenerate laser output, and the second-stage OPO is ordinary OPO output (degenerate or non-degenerate). The polarized light recycling resonant cavity is composed of the first resonant cavity and a ring cavity. The polarization beam splitting element 1 and the first cavity mirror 3 form the first resonant cavity; the polarization beam splitting element 1, the first mirror 4 and the second mirror 5 form a triangular ring cavity, and the three elements are located at three vertices of the triangular ring cavity . The polarization beam splitting element 1 is a common ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com