Wood fire retardant and its production

A fire retardant and wood technology, applied in the direction of wood impregnation, impregnated wood, wood processing equipment, etc., can solve the problems of damage to the physical and mechanical properties of wood, acid degradation of wood, pollution of the environment, etc., to achieve mild acidity and alkalinity, low hygroscopicity , to avoid the effect of deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

polyethylene glycol

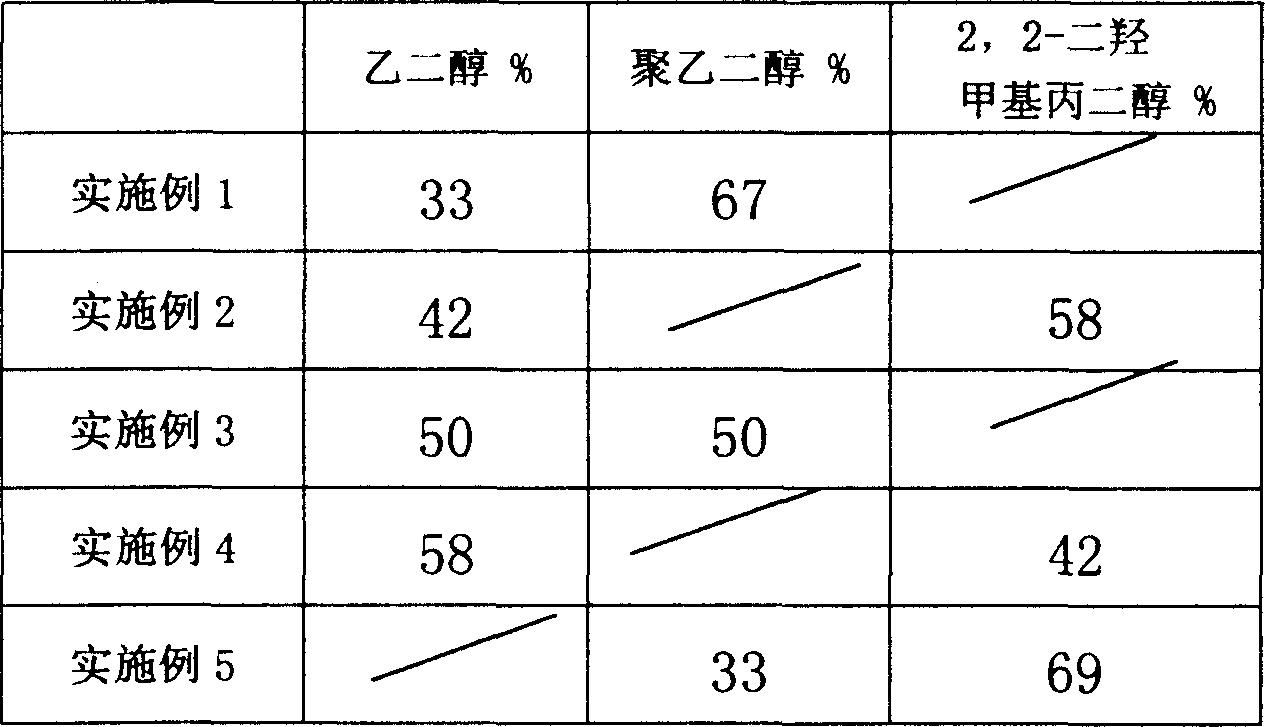

[0037] Table 3: Alcohol compound ratio table corresponding to each embodiment

[0038]

[0039] 70℃

85℃

95℃

105℃

120℃

Example 1

√

Example 2

√

Example 3

√

Example 4

√

Example 5

√

[0040] 1h

1.5h

2.5h

3.5h

4h

Example 1

√

Example 2

√

Example 3

√

Example 4

√

Example 5

√

[0041] The operation methods of the above-mentioned embodiments are the same, and the specific operation steps are as follows:

[0042] 1. Prepare amino compounds, aldehyde compounds, phosphorus-containing compounds, alcohol compounds and water according to different weight percentages, heat to dissolve, and react at 70-120°C for 1-4 hours.

[0043] 2. Add boron compounds to the above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com