Inorganic phosphor-contained polymer and its production

A technology for inorganic polymers and mixtures, applied in the field of phosphorus-containing inorganic polymers and their preparation, can solve the problems of dim practicability and high cost of alkali-induced slag cement, and achieve the effects of simple preparation process and wide service fields.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

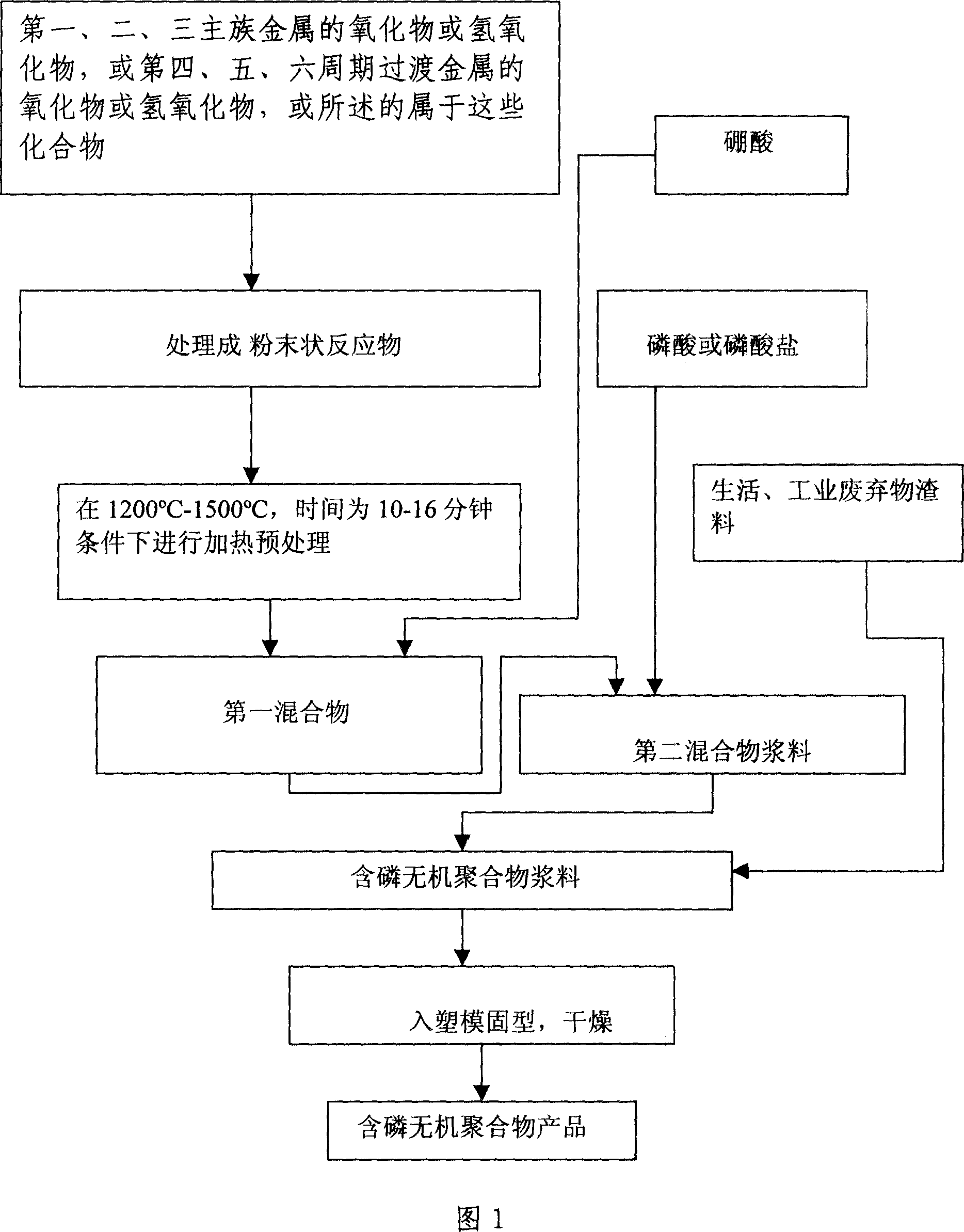

[0013] The present invention is based on the guiding idea that phosphorus-containing inorganic polymers can be used for the treatment and storage of hazardous wastes and the reuse of harmless wastes. waste for reuse. Specifically, the present invention relates to a phosphorus-containing inorganic polymer, including oxides or hydroxides of the first, second, and third main group metals, or oxides or hydrogen oxides of the fourth, fifth, and sixth-period transition metals Oxides, or the pretreated powdered reactants belonging to these compounds, and slags of domestic and industrial wastes, wherein the first mixture of the powdered reactants and boric acid is composed of the The slurry made of the first mixture and phosphoric acid or phosphate is the second mixture, a polymer slurry made of the second mixture and the slag of domestic and industrial wastes, wherein the The first mixture, the weight ratio of boric acid in the mixture to the powdered reactant is: (5-15): (95-85); t...

example 1

[0025] Example 1, an experimental example about the treatment and utilization of slag in Chengde Iron and Steel Company:

[0026] The gray-black slag from the slag mountain and the mixed oxide (content of Fe2O3 19%, MgO 67%, SiO2 14%, etc.) The concentration of the product is 95%, diluted to 50% before use) and boric acid, mixed according to the aforementioned ratio and processed according to the aforementioned process. No change in appearance.

example 2

[0027] Example 2, an experimental example about the treatment and utilization of waste residue from Xiangxi Electrolytic Manganese Plant:

[0028] The gray-green waste slag from the electrolytic manganese plant, mixed oxides (contents of Fe2O3 19%, MgO 67%, SiO2 14%, etc.) The concentration of the purchased product is 95%, diluted to 50% before use) and boric acid, mixed according to the aforementioned ratio and processed according to the aforementioned process, the resulting product is as hard as magnetism, and the appearance porosity is close to zero. and no change in appearance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com