Inactivated mixed vaccine for porcine respiratory disease and the method of manufacturing thereof

A porcine respiratory and inactivation technology, applied in the field of inactivated mixed vaccines for porcine respiratory diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Isolation and cultivation of viruses

[0027] For porcine Glasser's disease, in tryptic soy broth containing 45 μg / ml β-Nicotinamide adenine dinucleotide (β-NAD), 0.5% yeast extract, and 0.5% sucrose The S4 strain of Haemophilus parasuis and the S5 strain of Haemophilus parasuis (obtained from National Veterinary Research and Quarantine Service) were respectively cultured in (Tryptic Soy Broth, TSB) medium. The cultured strains were then isolated, lyophilized and cryopreserved at -80°C. The Mycoplasma hyopneumoniae J / 101 strain (obtained from the National Veterinary Research and Quarantine Service), which causes porcine enzootic pneumonia, was released and cultured in mycoplasma medium (Table 1). After isolation, the cultured Mycoplasma strains were lyophilized and cryopreserved at -80°C. Next, the Mycoplasma hyopneumoniae J / 101 strain was transferred to 1 / 3 volume of Mycoplasma medium (Table 1), and cultured for 7 to 10 days until the color of the medium t...

Embodiment 2

[0031] Example 2: Isolation and inactivation

[0032] For porcine Glasser's disease, each seed culture solution of Example 1 was released in TSB medium containing 45 μg / ml β-nicotinamide adenine dinucleotide (β-NAD), 0.5% yeast extract and Incubate at 37°C for 12 hours. The cultured strains were then isolated and concentrated, and inactivated using 0.3% formalin for 72 hours. For porcine enzootic pneumonia, M. hyopneumoniae J / 101 strain was transmitted in mycoplasma medium and cultured at 37°C for 7-10 days. Then, the cultured Mycoplasma strains were isolated and concentrated, and inactivated using 0.2% formalin at room temperature for 72 hours. For PRRS virus, porcine lung macrophages, porcine testis cell line (STL) cells or A-72 cells were inoculated with MN-HS or CNV-1 and cultured at 37°C for 3-5 days using a rotary culture system. When approximately 80% CPE was observed after virus inoculation, virus was isolated and inactivated using 0.1% formalin for 48 hours at room...

Embodiment 3

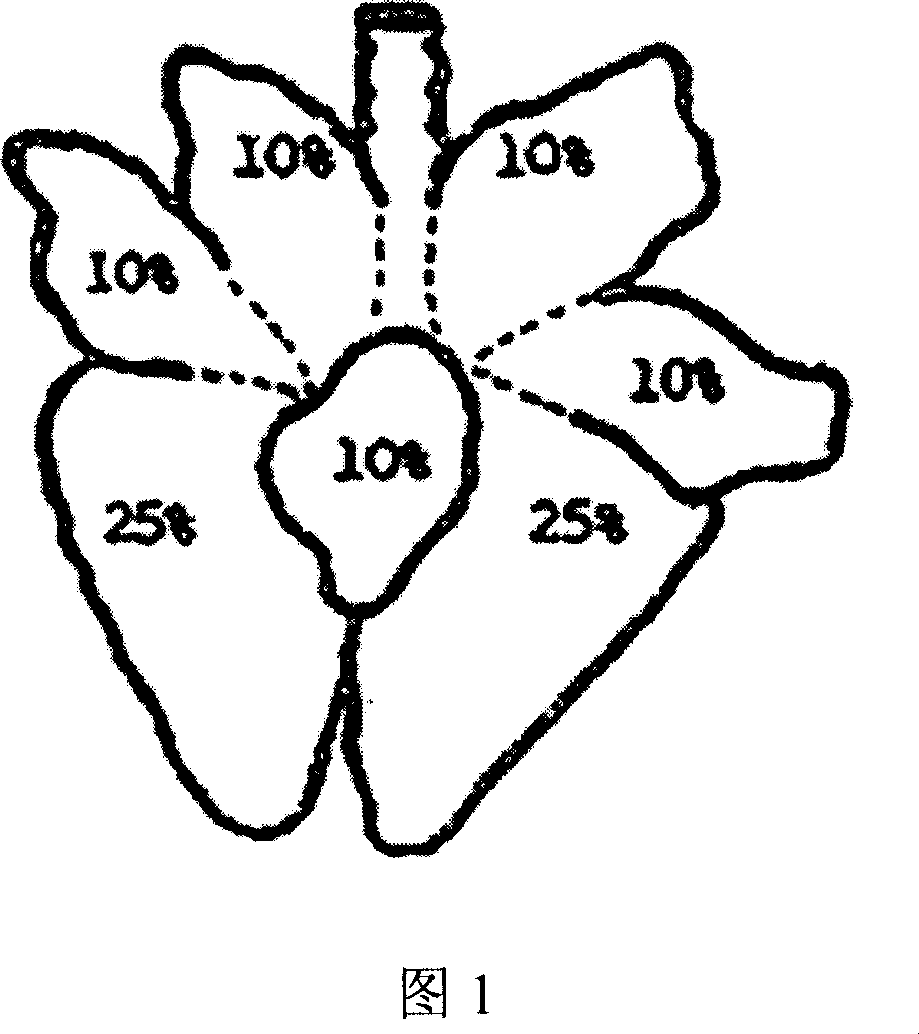

[0033] Embodiment 3: the preparation of inactivated mixed vaccine

[0034] The three antibodies of Example 2 were used to isolate strains, isolate pathogenic substances and inactivate various infection culture fluids. The total content of vaccine components is 30% (vol / vol) of the total mixed vaccine composition. The O.D. values of each vaccine component are as follows: Haemophilus parasuis S4 (410 nm, O.D 0.45), Haemophilus parasuis S5 (410 nm, O.D 0.45), Mycoplasma hyopneumoniae J / 101 (410 nm, O.D 0.1) and PRRS MN-HS (10 6.0 TCID 50 / ml). After mixing the vaccine composition, filter through a copper mesh. Then, use aluminum hydroxide gel 20% (vol / vol) to adsorb the filtered composition, then additionally add oil adjuvant (IMS 1313NPR) 5% (vol / vol) and EDTA 0.14% (weight / volume), and Mixing was carried out at 1000 rpm for 30 minutes to obtain a mixture. Next, an amount of the mixture was dispensed into bottles and stored in a cold room at 2-7°C. The resulting mixed v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com