Solid alcohol fuel and its preparing method

A solid alcohol and fuel technology, applied in solid fuel, fuel, petroleum industry and other directions, can solve the problems of short duration, storage, and insufficient combustion vacuum, and achieve good combustion performance, wide application range, and high combustion calorific value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

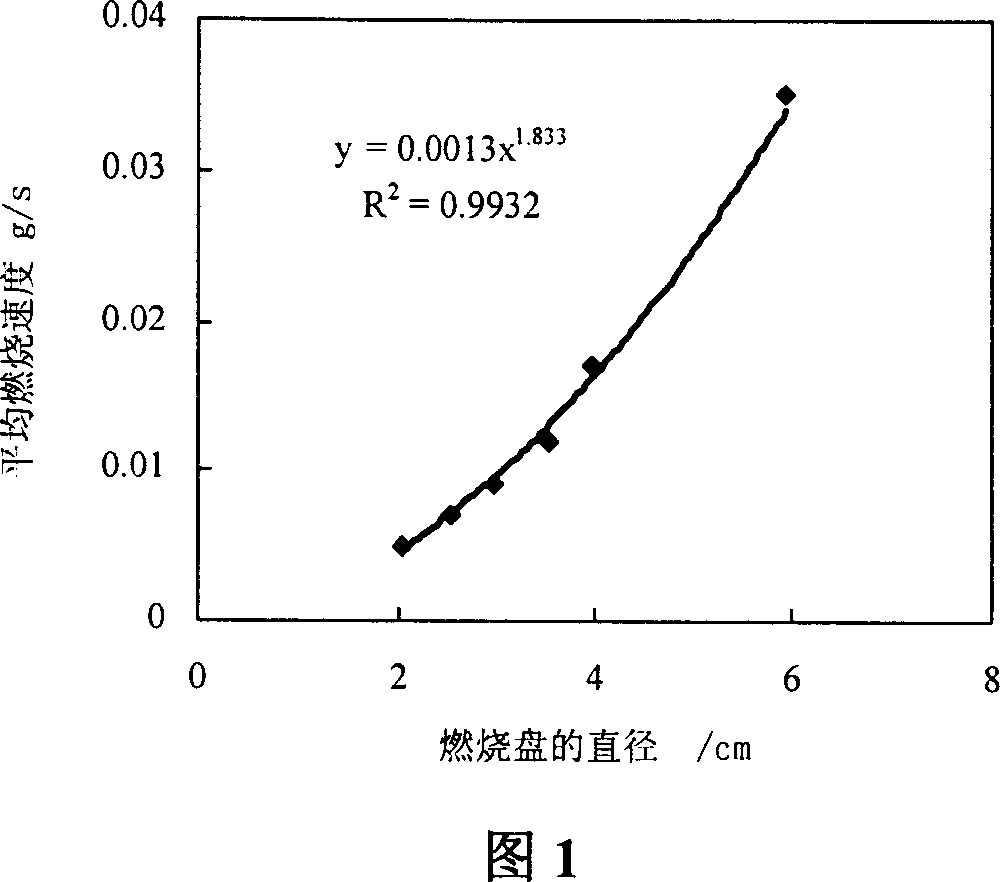

Image

Examples

Embodiment 1

[0038] Embodiment 1, the preparation of solid alcohol fuel

[0039] Raw materials: 1.3 grams of paraffin, 4.76 grams of stearic acid, 0.62 grams of NaOH, 90.73 grams of industrial alcohol, and 2.59 grams of distilled water.

[0040] Adopt two-step method to prepare solid alcohol fuel, experimental procedure is:

[0041] In the first step, stearic acid is dissolved in alcohol. The specific operation is as follows:

[0042] ①The temperature of the water bath in the fixed constant temperature water tank is 70°C, and the stirring speed of the electric stirrer is 250r / min.

[0043] ② Weigh stearic acid, paraffin and 50.55 grams of industrial alcohol respectively, and add them into a three-necked flask in turn. Then install an electric stirrer, a thermometer and a reflux condenser on the three-neck flask.

[0044] ③Heat and stir the three-necked flask in a water bath. A small amount of evaporated alcohol is condensed by the reflux condenser and returned to the three-necked flask...

Embodiment 2

[0049] Embodiment 2: the influence of each factor when preparing solid alcohol fuel

[0050] This example examines in detail the factors that have an impact on the quality of solid alcohol fuel products. In this experiment, the heating time in the water bath was 10 minutes, the mixing reaction time was 2 minutes, and the mechanical stirring speed was 250 r / min. Wherein the alcohol (alcohol 1) consumption is 50.55g in the three-necked flask, and the alcohol (alcohol 2) consumption is 40.18g (the whole material benchmark is 100g) in the Erlenmeyer flask.

[0051] 1. The influence of temperature

[0052] Based on the melting point of stearic acid being 67-70°C, the experimental temperature t=60°C, 65°C, 70°C, and 75°C were taken as four levels to investigate the influence of temperature on the experiment and the product.

[0053] The amount of raw materials required for the experiment is as follows:

[0054] raw materials and

stearic acid

Paraffin

Alcohol ...

Embodiment 3

[0079] Embodiment 3, the performance test of solid alcohol fuel

[0080] The solid alcohol fuels of the present invention used in this example are prepared by optimizing the process conditions and raw material ratios in Example 2. The similar product (reference substance 1) of contrast, raw material industrial alcohol 500ml, sodium hydroxide 2.5g, stearic acid 14.5g, paraffin 4.0g, water 10g are that main raw material is processed with the same process with embodiment 2. The control sample urotropine (reference substance 2) military solid fuel was purchased from Beijing Dongxin International Health Products Co., Ltd.

[0081] 1. Melting point experiment of solid alcohol fuel:

[0082] Experiment method: carried out in a stable super constant temperature water bath, the specific operation steps are as follows:

[0083]Before the measurement, lower the temperature of the water bath to 40°C, fix the small Erlenmeyer flask with the sample in the water bath, and heat it slowly. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com