Novel three dimension fabric knitting machine

A technology of three-dimensional fabrics and knitting machines, applied in the field of knitting machines, which can solve problems such as increased resistance, long intermediate transmission chains, shuttle movement and poor positioning accuracy, and achieve reduced machining volume, low processing costs, and small mechanical friction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

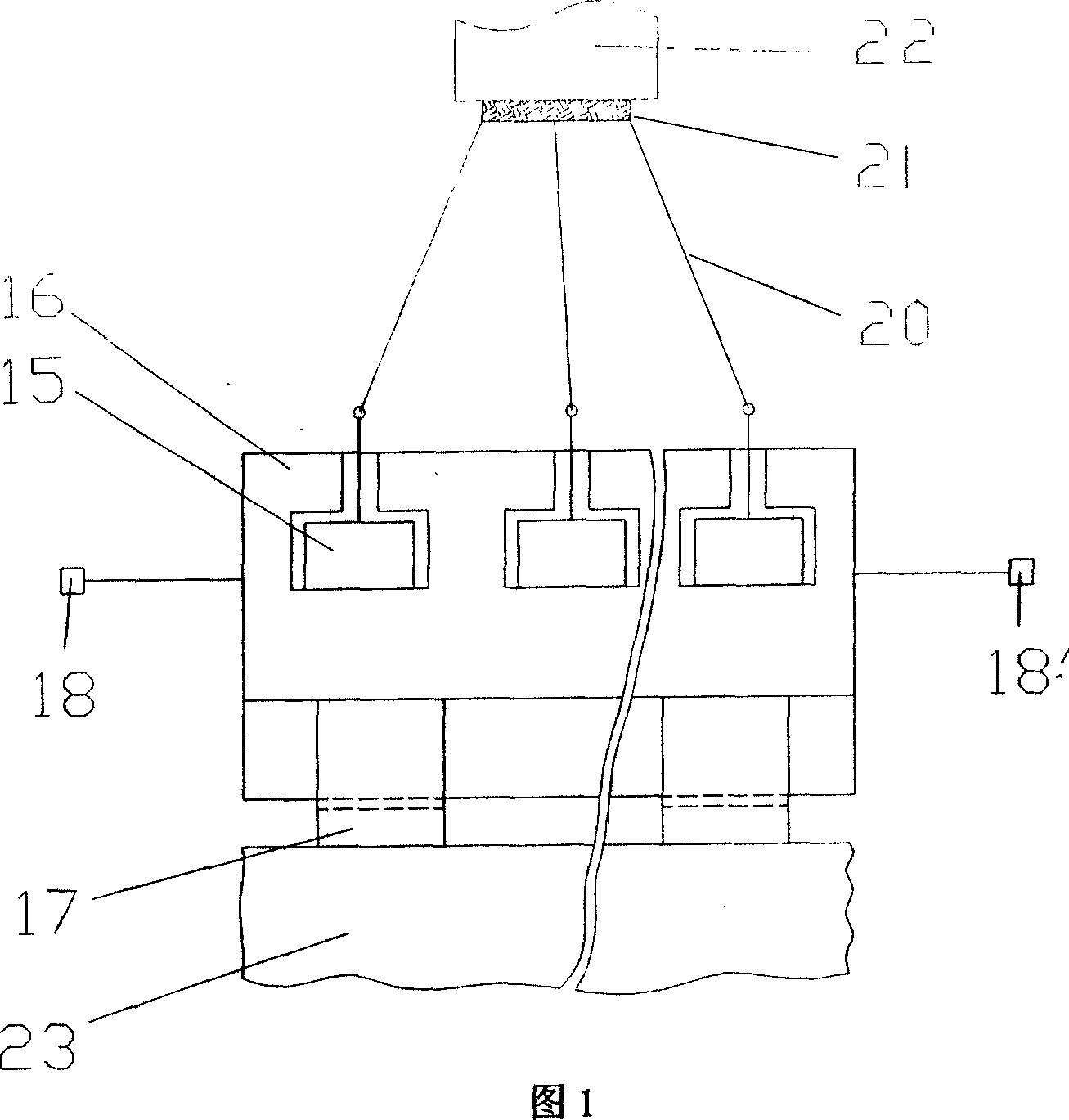

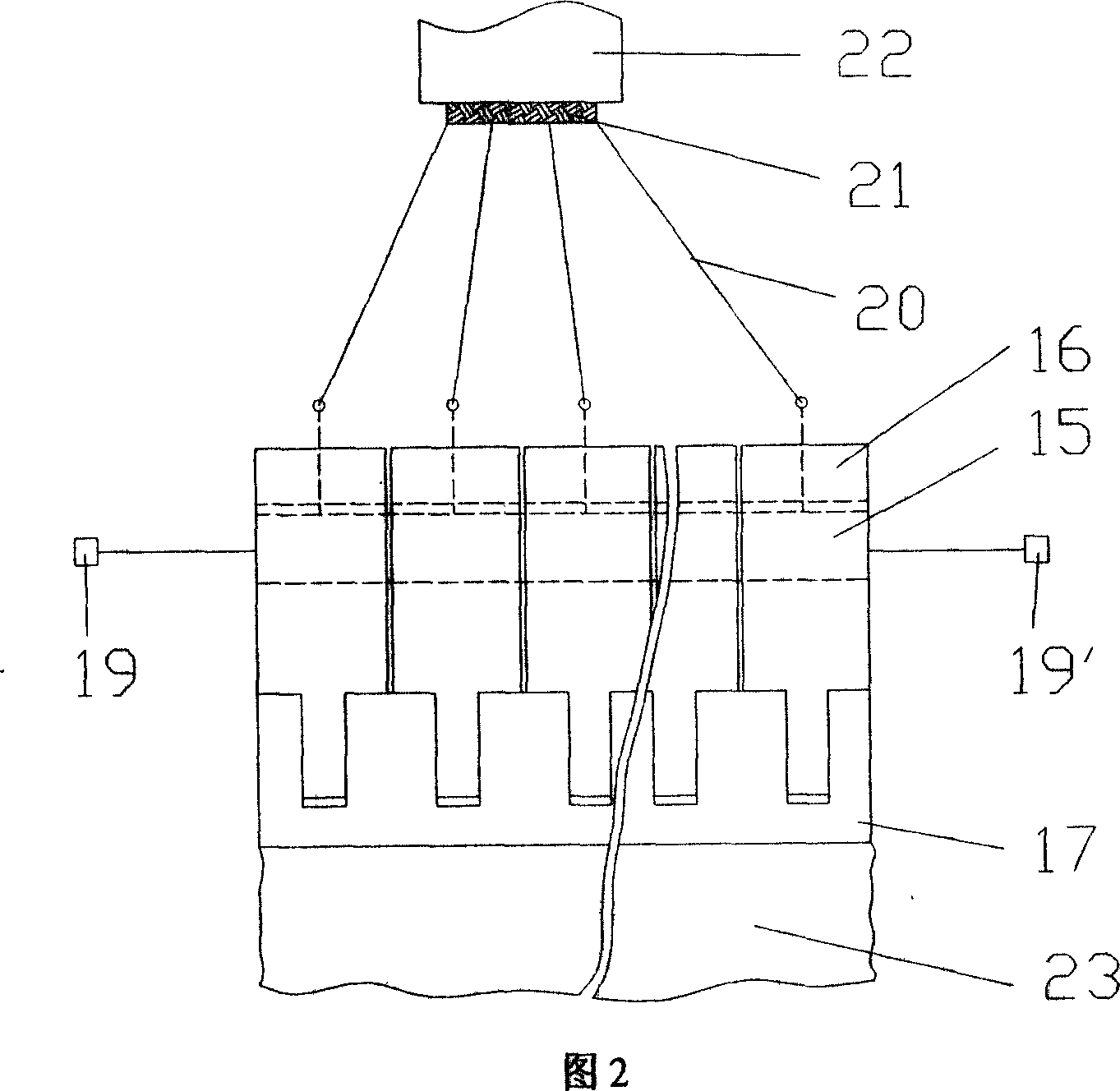

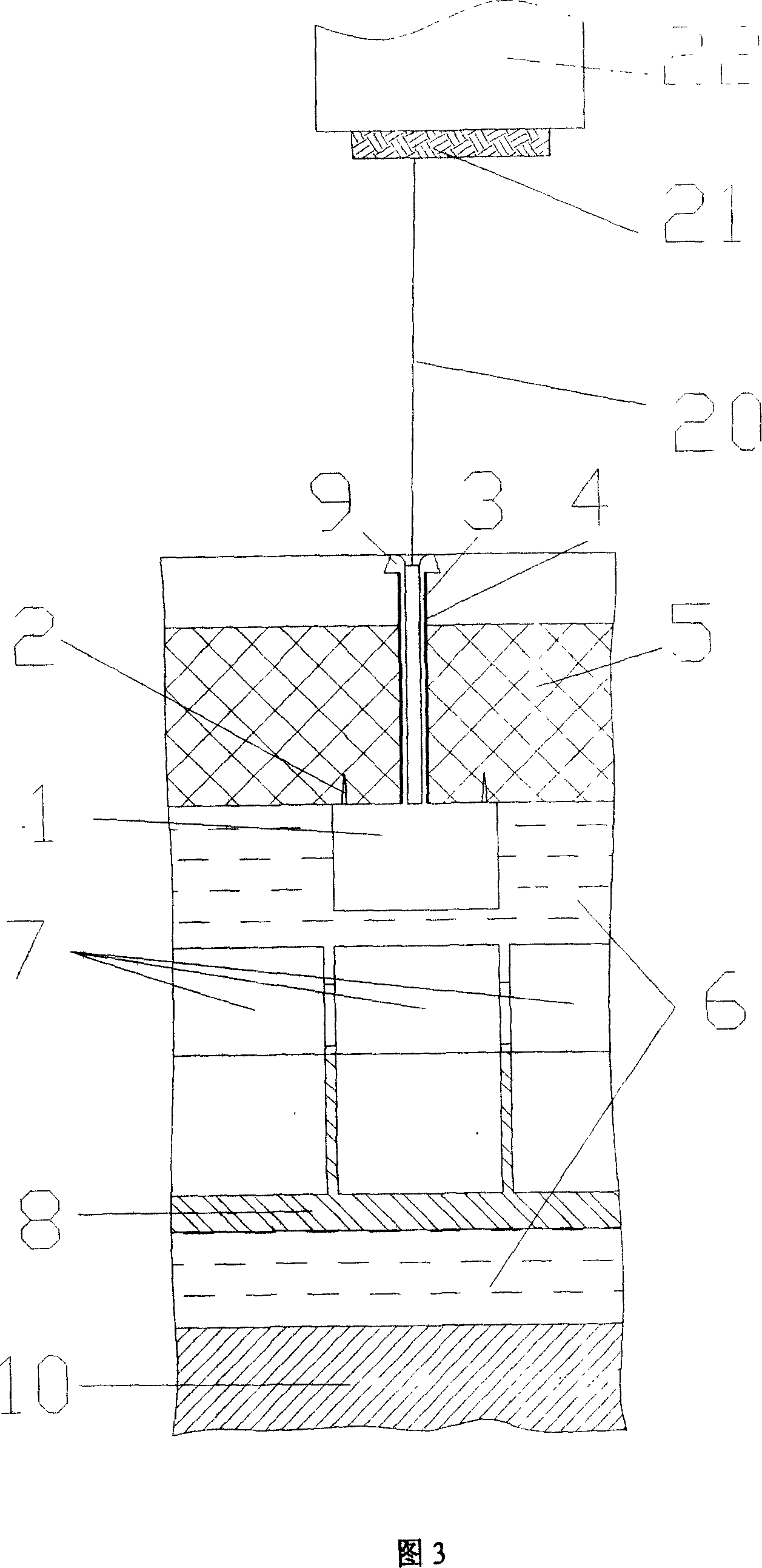

[0025]The knitting machine of the present invention keeps the structural form of the fabric forming device 22 in the traditional three-dimensional fabric knitting machine basically unchanged, and its key point is to redesign the chassis of the knitting machine (see Fig. 3). The solid-liquid two-phase chassis is composed of two different material layers, the upper and lower layers. The chassis function is completed through the specific material properties of the upper and lower material layers. Among these two layers, the upper layer 5 is called the solid phase layer, and the lower layer 6 is called the solid phase layer. liquid layer. Shuttle is made up of yarn storage device 1, yarn bobbin 3, heating wire 4, increases the fixed cone 2 and stop cap 9 that play auxiliary role simultaneously. Shuttle is driven by driving arm 8, and driving hand 7 realizes various knitting motions. There is a detachable docking interface between the yarn storage device 1 of the shuttle and the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com