Photoelectric cathode and process for preparing vacuum ultraviolet electric device using said cathode

A technology of vacuum ultraviolet light and photocathode, which is applied in the direction of photoemission cathode, cold cathode manufacturing, electrode system manufacturing, etc., can solve the problems that cannot be carried out step by step, pollution, etc., reduce requirements and energy consumption, solve pollution, and facilitate The effect of using the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings.

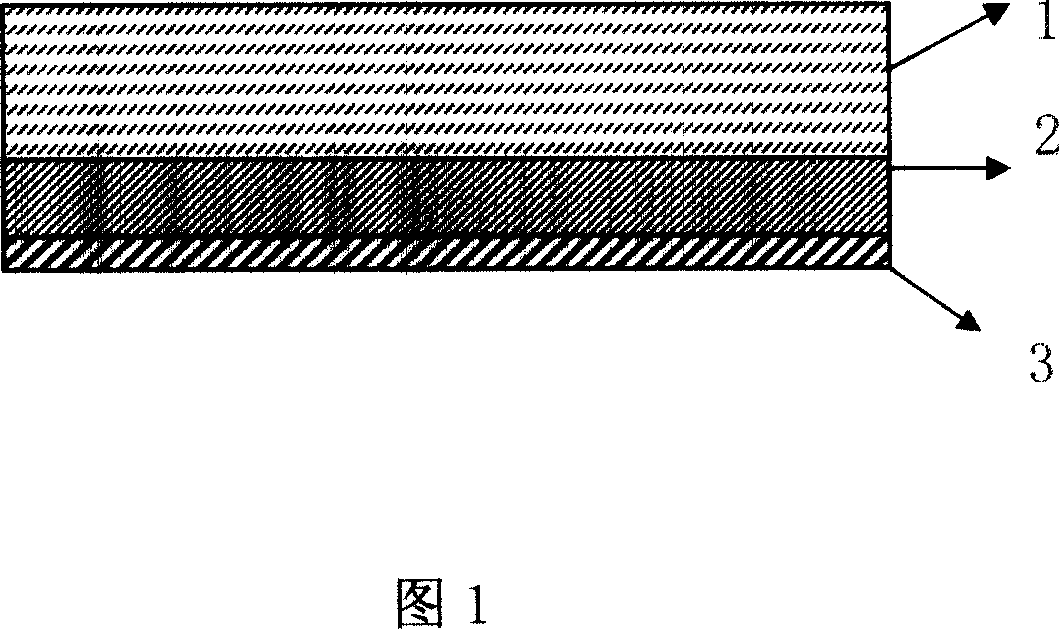

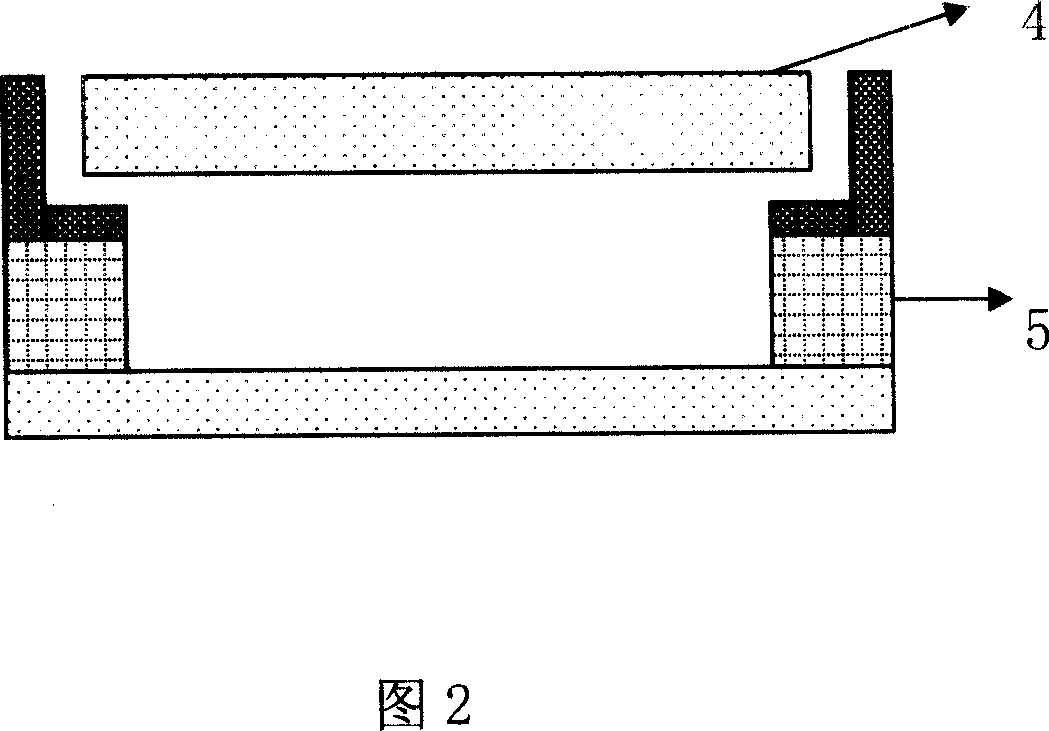

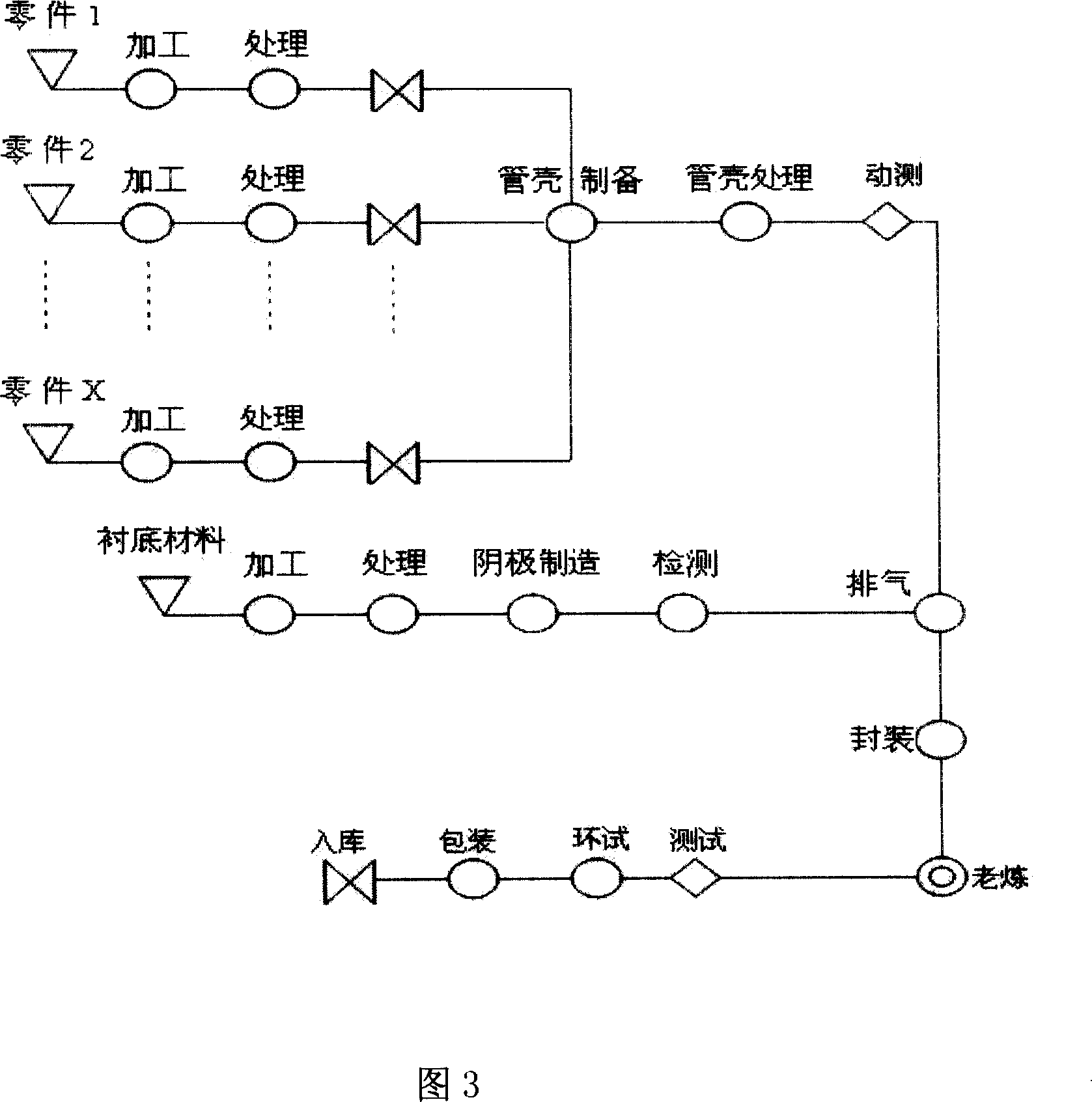

[0039] Fig. 1 is the structural representation of the zinc oxide photocathode provided by the present invention, and Fig. 2 is the structural representation of the zinc oxide photocathode vacuum ultraviolet device provided by the present invention, wherein, 1, transparent purple base material, 2, transparent conductive layer film, 3. Zinc oxide thin film or nanowire array layer, 4. Photocathode, 5. Shell of photoelectric device. The photocathode is composed of three composite layers, the base layer is made of a transparent base material 1 with a small character distortion, the middle layer is a transparent conductive layer film 2, and a zinc oxide film or a nanowire array layer is arranged on the conductive layer 3. The purple transparent base material 1 is sapphire or quartz, the transparent conductive layer film 2 is metal chromium film or zinc oxide film, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com