Lift force control method of rotating wing fan and vertiautomobile

A technology of a rotor fan and a control method, which is applied to convertible aircraft, rotorcraft, aircraft, etc., can solve the problems of questionable reliability and safety, high cost, and difficulty in adapting to long-distance driving on roads.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0004] The purpose of the present invention can be achieved through the following technical solutions:

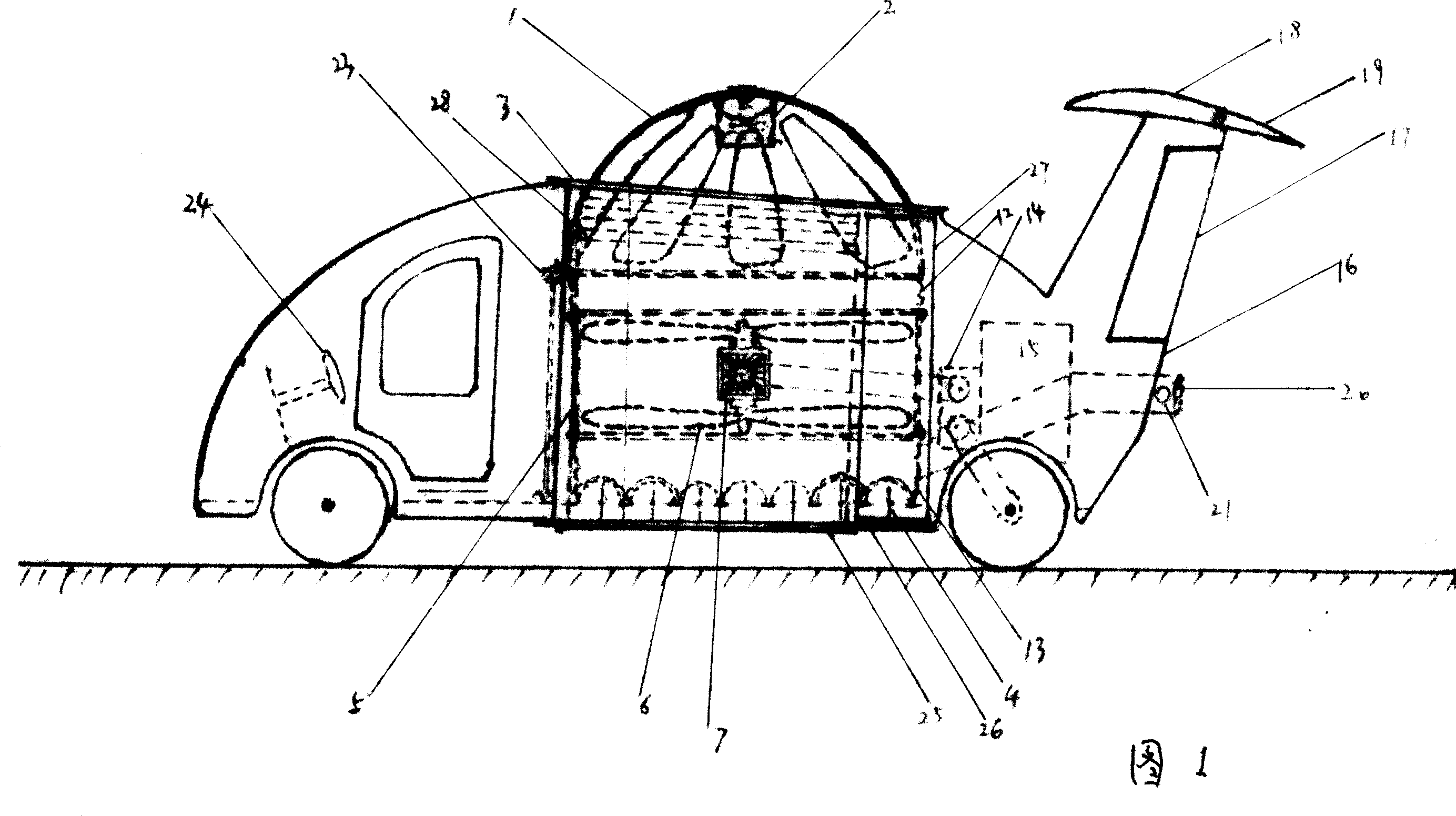

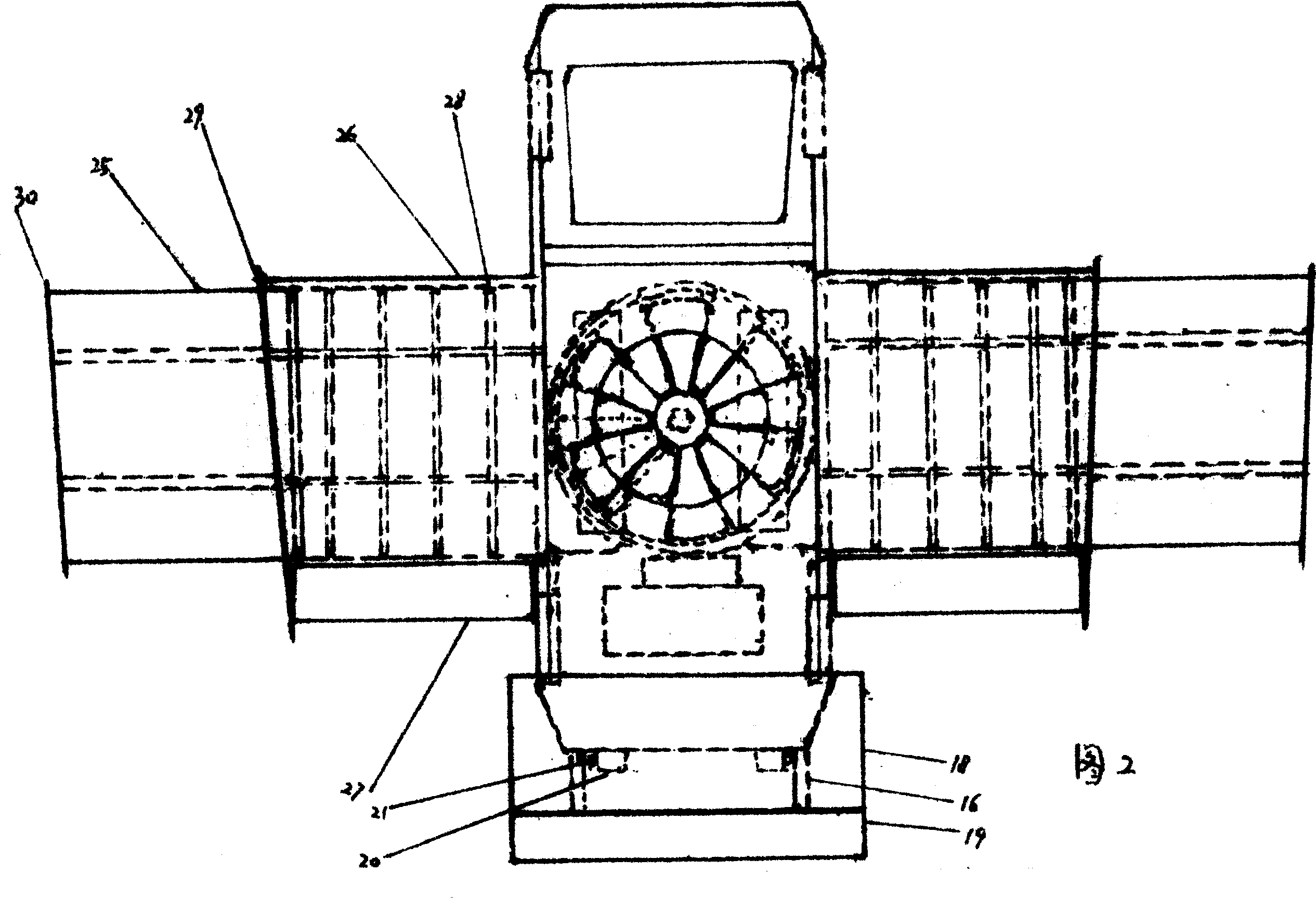

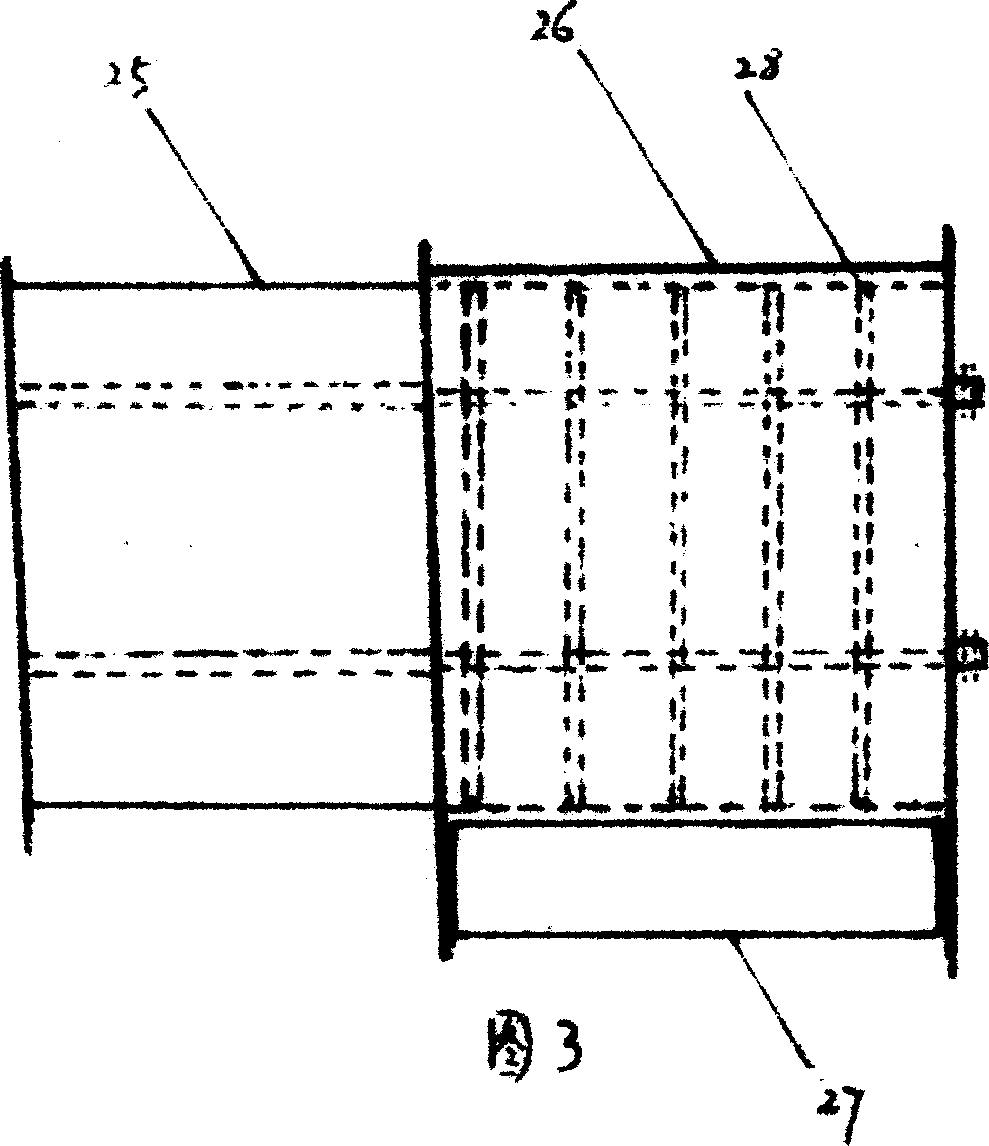

[0005] On the air inlet of the reciprocally reversible double-rotor ducted lift fan cylinder 5, (connected through the bendable compensation joint 12) is installed a relatively rotatable double layer (made of light metal, alloy or composite material with equally spaced louvers) The air intake volume (air flow) control valve 1 (Fig. 8) formed by a hemispherical shell (or semi-ellipsoidal shell) is directly regulated by the opening and closing of the actuating mechanism 23 by relatively rotating the hemispherical shell (semi-ellipsoidal shell) and adjusting the ventilation area of the louver. Air volume (linkage regulation engine throttle) controls the lift that fan rotor 6 (Fig. 13) produces. There is an emergency parachute storehouse 2 in the center of the top of the shell, and the parachute is folded and stored, and can be compressed air (or the explosive method of burni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com