Reuse technology of oil refining, chemical catalyst production waste water

A technology for producing wastewater and catalysts, which is used in biological water/sewage treatment, chemical instruments and methods, and multi-stage water/sewage treatment. cost, solving technical problems, and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

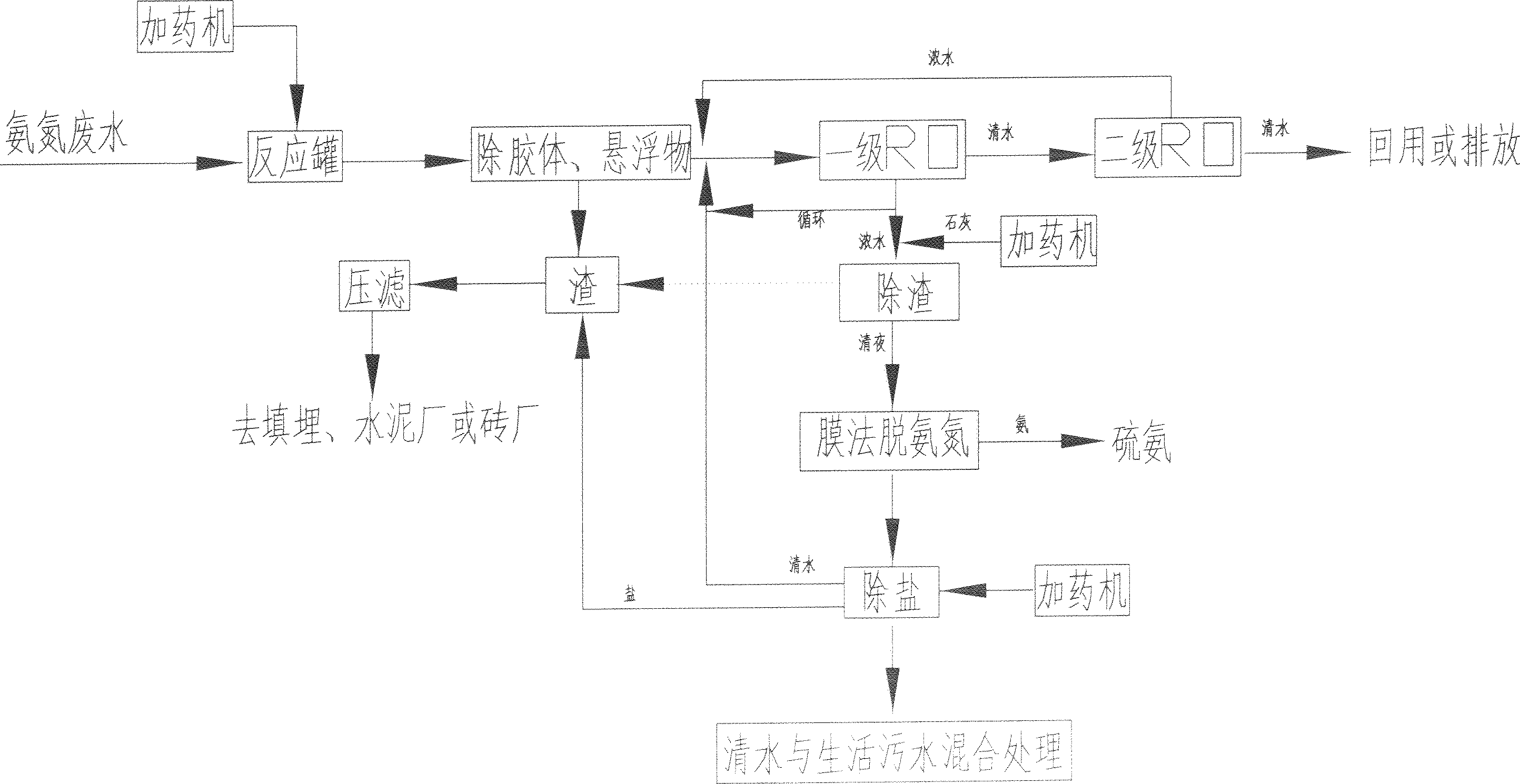

[0033]Ammonia nitrogen wastewater is pumped into the reaction tank, and chemicals A and B are added to the reaction tank to form large particle flocs of silicon, aluminum and suspended solids, and then enter the degumming and suspended solids removal device. The content of silicon and aluminum in the effluent is less than 10ppm, suspended The clean water with less than 50ppm of solids enters the primary reverse osmosis system, and the waste residue formed by colloids and suspended solids is transported to landfill, cement factory or brick factory; the clean water treated by the primary reverse osmosis system is used as the feed water of the secondary reverse osmosis system. The salt content of the clean water in the secondary reverse osmosis system is below 1ppm, the ammonia nitrogen is 0, and the turbidity is 0. The clean water can be directly reused or discharged, and the concentrated water of the secondary reverse osmosis system is returned to the water inlet tank of the prim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com