Preparation method of cellulose film

A cellulose film and cellulose technology, applied in the field of cellulose film preparation, can solve the problems of unsuitability for expanded reproduction, not suitable, long time, etc., and achieve low production cost, increased reactivity, and fast degradation speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

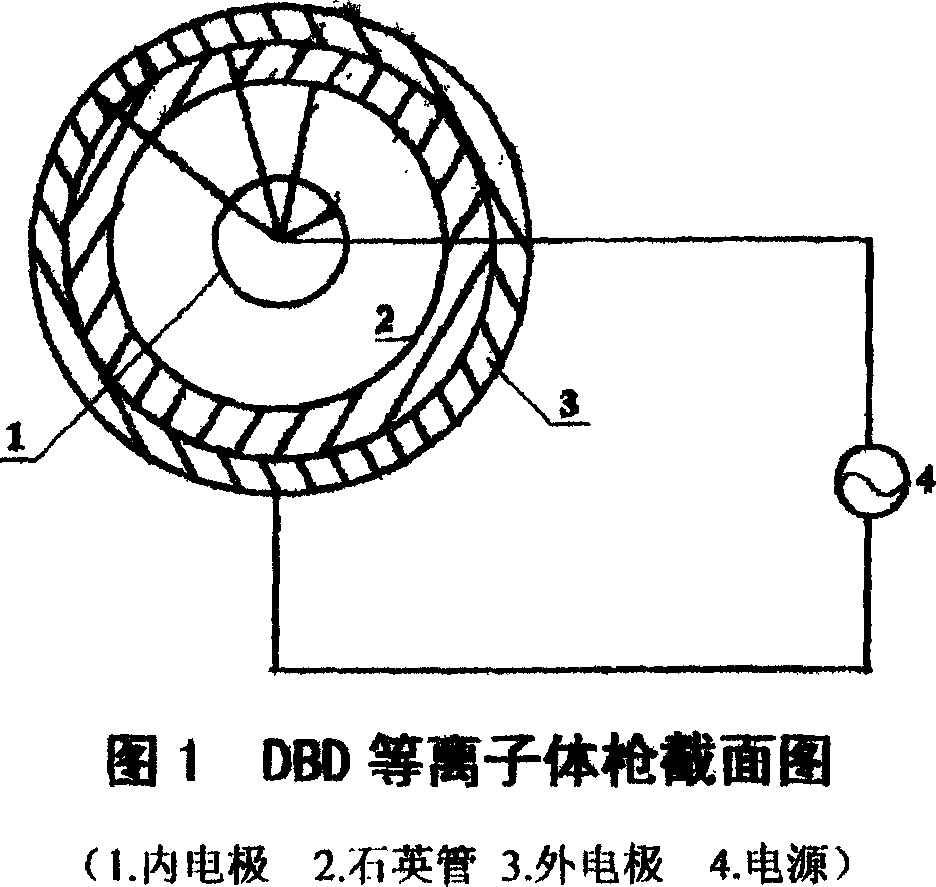

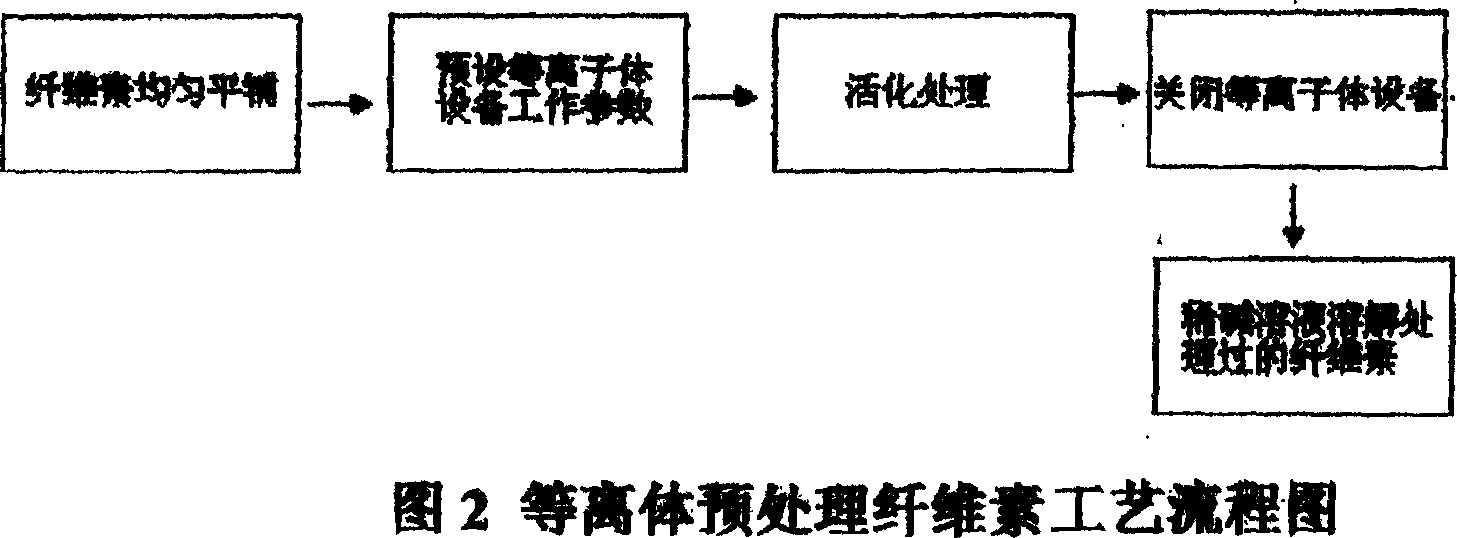

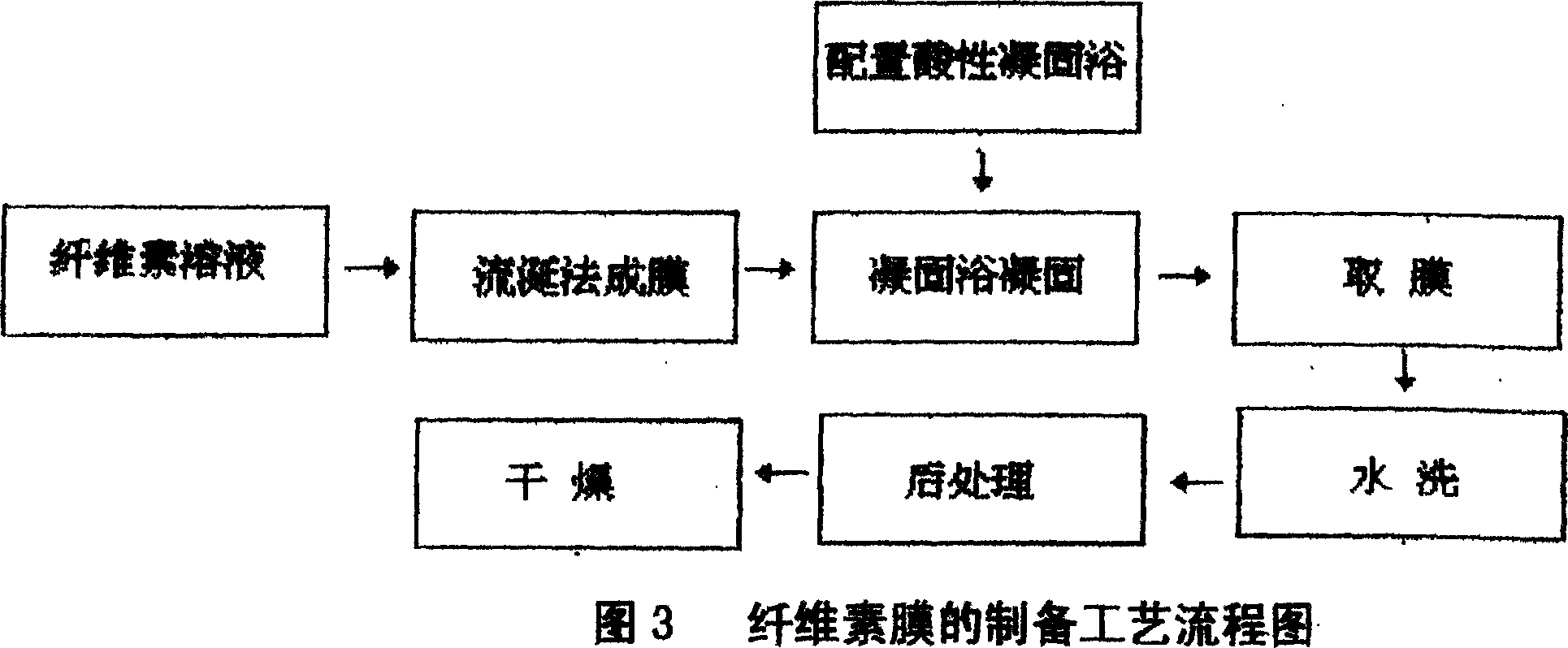

[0032] Spread 20g of cotton cellulose pulp with a degree of polymerization of 450 into a uniform thin layer and put it in a plastic tray with a thickness of 2-3mm. Place the plastic tray directly under the plasma gun. The output power of the adjustable voltage power supply is 120w and the frequency is 25KHz. , open the gas valve to pass Ar gas, the gas flow rate is: 10L / min, and the lignocellulose pulp is irradiated. After irradiating for 30 seconds, turn off the power and gas valve. Then the irradiated lignocellulose pulp was dissolved in 500 liters of 6% NaOH aqueous solution, and stirred and dissolved with a 1 liter three-neck flask. The mixer is at 60 rpm, and the stirring temperature is around 0°C. The stirring and dissolving time is about 30 minutes. Then let it stand for degassing for 3 hours to obtain a transparent lignocellulose film-forming liquid for subsequent use. Then scrape the dissolved lignocellulose film-forming liquid into a film with a thickness of 0.2 m...

Embodiment 2

[0035] Spread 20g of wood cellulose pulp with a polymerization degree of 500 into a uniform thin layer and put it in a plastic tray with a thickness of 2-3mm. Place the plastic tray directly under the plasma gun. The output power of the adjustable voltage power supply is 120w, and the frequency is 25KHz. , open the gas valve to pass Ar gas, the gas flow rate is: 10L / min, and the lignocellulose pulp is irradiated. After irradiating for 30 seconds, turn off the power and gas valve. Then the irradiated lignocellulose pulp was dissolved in 500 liters of 6% NaOH aqueous solution, and stirred and dissolved with a 1 liter three-neck flask. The mixer is at 60 rpm, and the stirring temperature is around 0°C. The stirring and dissolving time is about 30 minutes. Then let it stand for degassing for 3 hours to obtain a transparent lignocellulose film-forming liquid for subsequent use. Then scrape the dissolved lignocellulose film-forming liquid into a film with a thickness of 0.2 mm on...

Embodiment 3

[0038] Spread 20g of cotton cellulose pulp with a degree of polymerization of 450 into a uniform thin layer and put it in a plastic tray with a thickness of 2-3mm. Place the plastic tray directly under the plasma gun. The output power of the adjustable voltage power supply is 120w and the frequency is 25KHz. , open the gas valve to pass Ar gas, the gas flow rate is: 10L / min, and the lignocellulose pulp is irradiated. After 60 seconds of irradiation, turn off the power and gas valve. Then the irradiated lignocellulose pulp was dissolved in 500 liters of 6% NaOH aqueous solution, and stirred and dissolved with a 1 liter three-neck flask. The mixer is at 60 rpm, and the stirring temperature is around 0°C. The stirring and dissolving time is about 30 minutes. Then let it stand for degassing for 3 hours to obtain a transparent lignocellulose film-forming liquid for subsequent use. Then scrape the dissolved lignocellulose film-forming liquid into a film with a thickness of 0.2 mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com